Henan HTX Group Co., Ltd. |

|

Verified Suppliers

|

|

Product Description

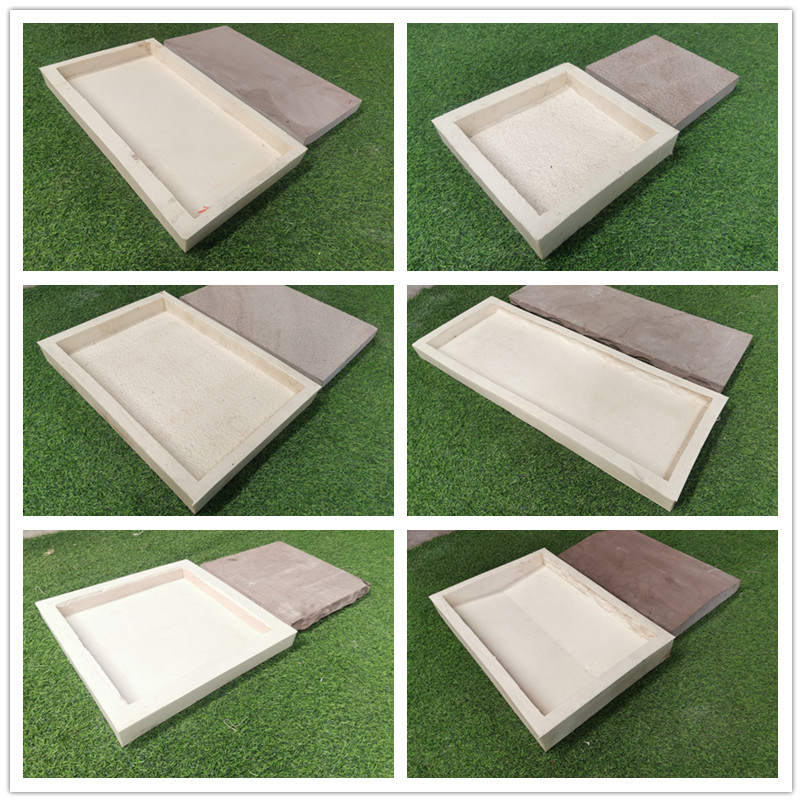

Wet cast concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .The mold is turned over from one conveying platform to another conveying platform through the turning frame, so as to realize the turning of the mold and prepare for the subsequent demoulding. Also we have many kinds of designs silicon mould for make artificial stone. The silicon moulds are very durable. Each mould can be used 2000 times at least. Turning over the pallet with molds by 180C,place the molds and catch back the empty pallet to the main hydraulic conveyor. · Hydraulic(turning) +Pneumatic (pallet&molds control) · Pallet turning speed is adjustable(frequency motor controller) · With transport roller conveyor for shipping the molds to the demolding machine Here are some cultural stone molds. If you are interested, we can send you relevant catalogs and more styles

Specifications

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Wet Cast Machinery | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Applications

Auto Wet Conrete Dosing System Production line advantages:

1.More efficient production, can achieve 800M2 Per day(8hrs)

2.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

3.Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4. The auto spray painting machine, has function for mold oil sparying, stroll color painting and full color painting, also it can be turned on/off separately.

Feature advantage

Henan HTX Group Co Ltd, specialized in designing, developing, producing and marketing of artificial stone molds, paving tile molds, concrete stamp molds, pillar molds, roman column molds, and relative machines and production lines.we have more than 200 mould designs and sizes. The updated silicone material make the stone mold more durable and have good characteristic. After use again and again,our updated silicone mould still have a clear & natural texture and without any deformation.

Related Products

Certificate