Henan HTX Group Co., Ltd. |

|

Verified Suppliers

|

|

Product Description

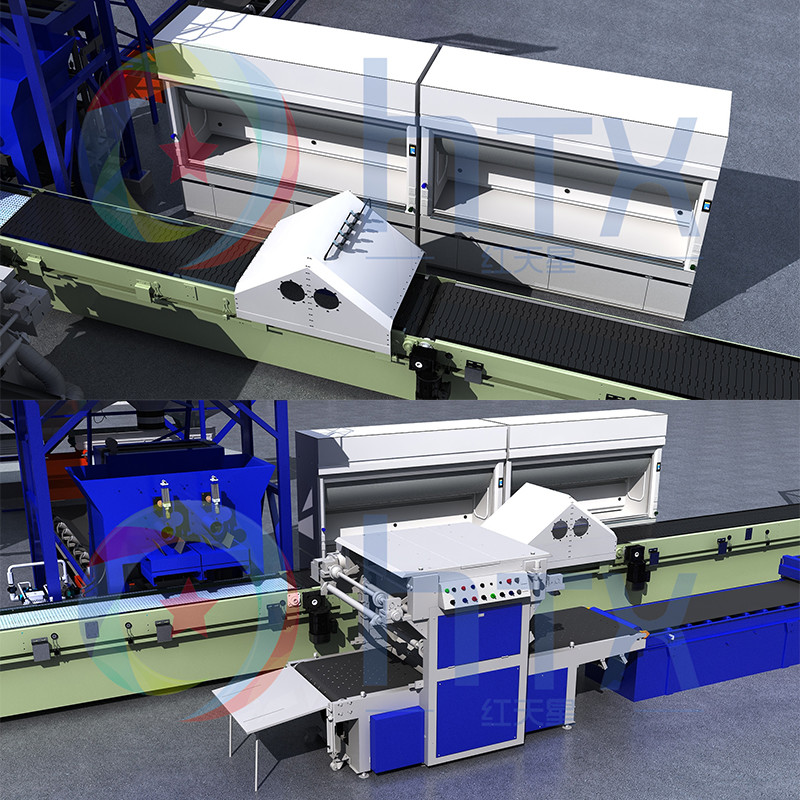

wet cast concrete machinery uses single-silo ingredients. Your cement can be directly

transferred to the mold through the silo, and conveyed through the

transmission belt to improve production efficiency. The daily

production output is 500-600 square meters, which is completely

impossible for manual production lines.The length of the entire

production line is 8 meters, which can be expanded to 15 meters

according to demand, requiring a workshop space of 300-400 square

meters; it has the functions of timing cutting, timing vibration,

and fixed-point transmission.

Specifications

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

|---|---|---|---|---|---|---|

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Applications

Specializing in the manufacture of fully automatic Wet Cast Equipment for more than ten years, which can be customized according to

customer requirements(the size of the factory, size of the molds

and shape of the molds), it is suitable for all kinds of precast

concrete molds of different quality,different specifications and

different shapes of cultural stone, wall and floor paving, 3D Wall

panel, terrazzo floor tile, etc .From formulated raw materials to

demoulding and packaging. All can be automated, save time and

effort.

Feature advantage

In order to improve the production rate, we designed two types of artificial stone production line. They are semi auto production line and full auto production line. It not only improve the production efficiency but also lower the labour quantity and cost. It will be a good choice for artificial stone producing.

We offer more than 300 coloring ingredient technical support, train your worker from the start to the end for artificial stone coloring process, this will help you make this business much easier.

Related Products

Certificate