Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Lightweight Fire clay Porous insulation refractory bricks

Clay brick is the refractory brick with 30%- 48% alumina content. Clay brick is weak acid product. Because of its rich resources, simple production process, low cost, it is widely used.

Grade | 40 - 48% Alumina Fireclay Bricks | 30 - 35% Alumina Fireclay Bricks | ||

Recommended Service Temperature | 1600℃ | 1500℃ | ||

Bulk Density | g/cm3 | 2.2 | 2.1 | |

Apparent Porosity | % | 22 | 24 | |

Modulus of Rupture | kg/cm2 | 90 | 80 | |

Cold Crushing Strength | kg/cm2 | 300 | 250 | |

Linear Expansion @ 1350℃ | % | 0.2 | 0.2 | |

Refractoriness Under Load | ℃ | 1450 | 1300 | |

characteristics of fire clay bricks:

1,high density

2,good thermal shock resistance

3,excellent volume stability at high temperatures

Lightweight clay refractory brick is with a light weight, small thermal conductivity and high refractoriness. Its drawback is high air permeability, loose structure, low mechanical strength, anti-slag and poor anti-harmful gas erosion ability, easily to be damaged in long-term use. Therefore, the density of 0.4-0.8g / cm3 fireclay products are generally used as high temperature insulation components, the density of 1.0-1.3g / cm3 fireclay product as an insulation wall between industrial boiler pipe.

The chemical and physical index of lightweight insulation fireclay brick

Related information

Category of High Alumina Refractory Bricks:

a) According the made method, it can be divided into burnt brick, unburned brick, and electric smelting brick.

b) According the shape and size, it can be divided into standard brick, general brick and abnormal shape brick.

c) According the content of the Al2O3, it can be divided into fire clay brick and high alumina firebrick.

Lightweight Fire clay Porous insulation refractory bricks

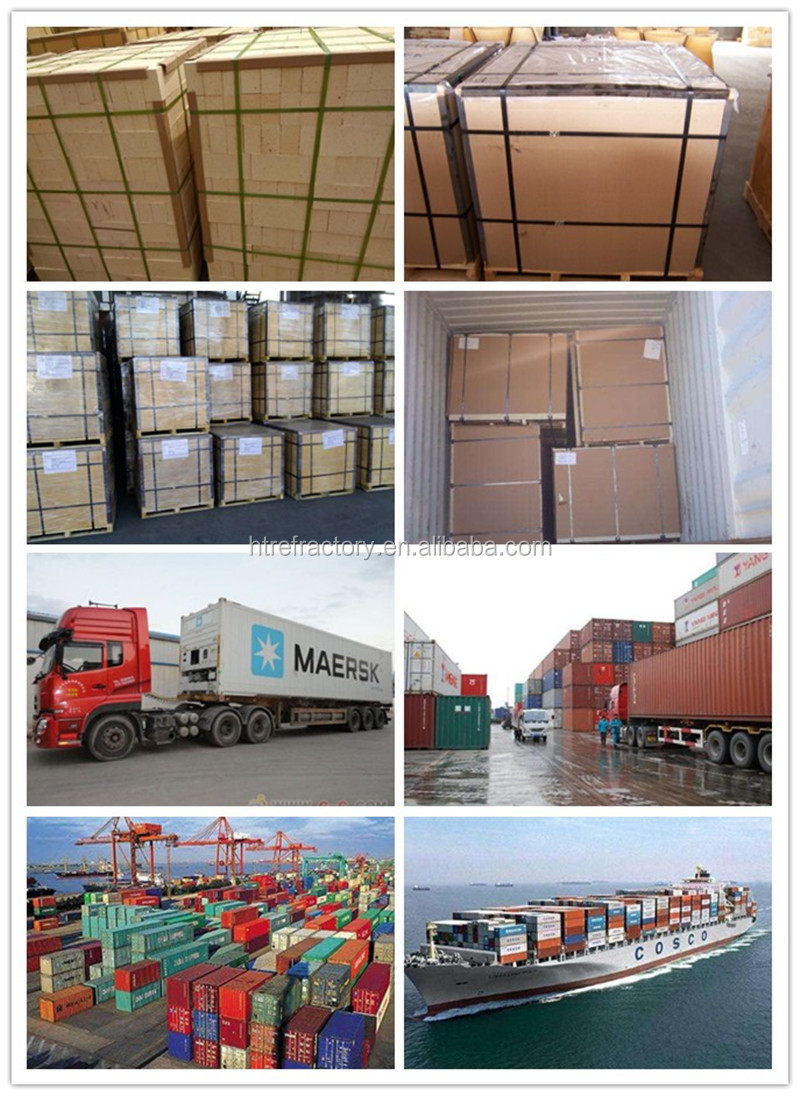

Packaging of fireclay bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of fireclay bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

Lightweight Fire clay Porous insulation refractory bricks

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to

the chemical content,raw materials are classified into different

levels to ensure quality of brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management: inspection of product

standardization of quality of each product by process control and

experimentation, taking corrective measures timely whenever

deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance,

physical and chemical properties of brick again in factory.

Lightweight Fire clay Porous insulation refractory bricks

1. Strong professional:

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory' s production materials, process control, quality supervision and package delivery, and ensure the products are 100% qualified.

1. How can I get your prompt quotation?

We can give you reply with quotation quickly if you kindly send the inquiry with the detail, such as the quantity, the specifications and the application of the products.

2. What is the MOQ (minimum order quantity)?

100 pcs is OK.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don't conform to customer's samples or have quality problems, our company will be responsible to make compensation for it based on enough evidences.

Contact Us about more information of refractory bricks and materials.

Contact: Marina Ma

Phone: +86 18838001797

Whats App: +86 18838001797

We chat: +86 18838001797

Email: sales04(at)firebricks-supplies.com