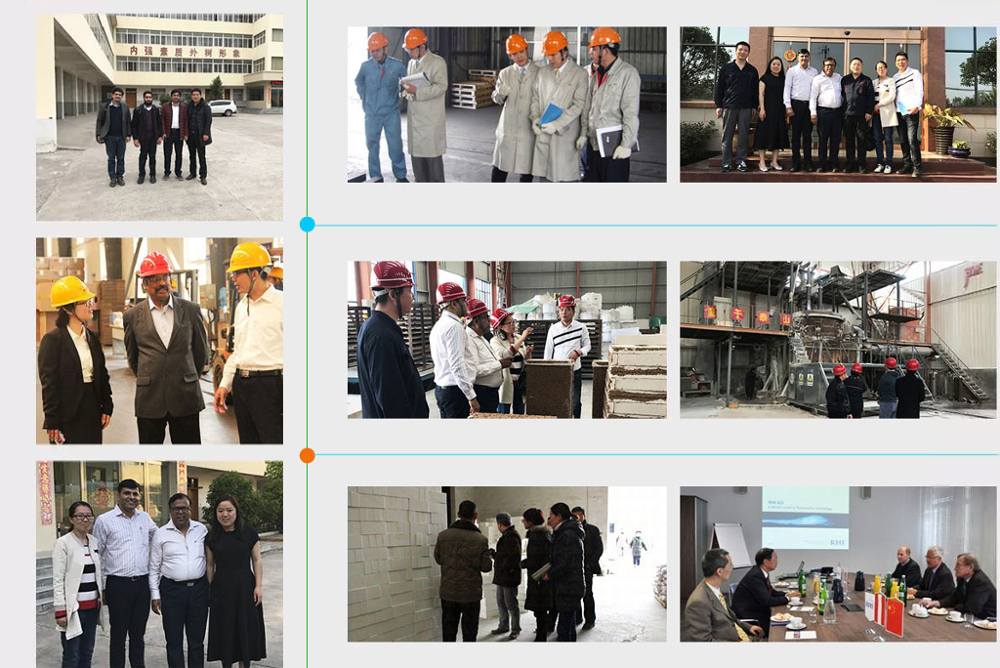

Henan hongtai kiln refractory co., LTD. Is well aware that there

are thousands of demands from customers, which can be summarized in

four aspects: reliable quality, timely delivery, reasonable price

and considerate service.The company will continue to adhere to the

corporate spirit of "contributing to society and serving customers"

and the business philosophy of "mutual benefit, win-win, integrity,

efficiency, preciseness and responsibility".Our company is willing

to develop a wide range of technical exchanges with colleges and

universities and colleagues from all walks of life at home and

abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. Main products are high

alumina brick, clay brick, mullite brick, fused zirconium corundum

brick, fireproof ball lightweight insulation brick, wear-resistant

pouring material, corundum pouring material, low cement high

strength pouring material, impermeable material, self-flowing

material, plastic material, and various types of refractory

materials.For different industries, the cement industry with

anti-flaking high-alumina bricks, alkali resistant bricks,

phosphate bricks;Boiler industry USES all kinds of brand

wear-resisting brick, corundum brick, mullite brick and other

finalizing materials.The company insists on "product quality is the

life, enterprise integrity is the foundation", in the fierce market

competition, won many users' trust and praise.The products are sold

all over the country, as far as Vietnam, India, South Korea,

Pakistan, Kazakhstan, Malaysia and other southeast Asian countries

and regions.

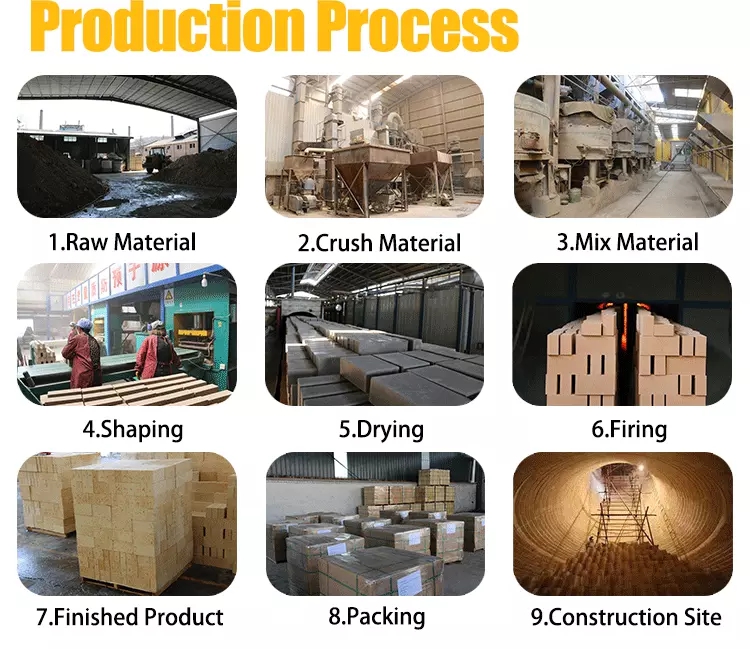

Henan hongtai kiln refractory co., LTD. : "quality first,

reputation first, customer first: it is our aim."Scientific

management,

strong technical force, perfect testing means, advanced

technological equipment and stable product quality are the

guarantee of quality service.Henan hongtai kiln refractories co.,

LTD sincerely hopes to cooperate with you hand in hand and in good

faith.