Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Lower price andalusite brick anode baking furnace

Profiles made from andalusite calcined can be used in key parts

such as hot blast stove, hot air tower, reheat frying, etc., can

also be used in a variety of auxiliary pouring and operating

equipment, and can also be used in the production of kiln

facilities, high-temperature aluminosilicate insulators, and

foundry mold fabrics.

Andalusite firebrick made from andalusite can save 30 ~ 50% energy

compared with refractory or light brick lining.The use of

andalusite firebrick can not only reduce the fuel consumption and

increase the stability, but also save more than 40% of the

consumption of common refractory materials.

As a high temperature structural material, hot blast stove brick requires very strict creep rate at high temperature.Andalusite and sillimanite have excellent high temperature structural strength properties.Table 1 lists the performance comparison between andalusite and mullite, bauxite, corundum and other refractory products.It can be seen from Table 1 that the high temperature creep rate of andalusite brick is better than that of bauxite, corundum and most mullite bricks. Andalusite is one of the ideal materials for low creep refractories.

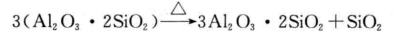

Sillanite, andalusite and kyanite have the same heating phase

transformation behavior, and they all decompose to form mullite and

SiO2 phases, the latter can form either quartzite or glass

phase.The difference is that the volume expansion of sillimanite

and andalusite into mullite is small.While kyanite is very large,

its reaction is carried out as follows:

Since sillimanite and andalusite have only a small volume effect in

the hot mullite process, they can be directly used to make

bricks.It can be burnt or not.The content of Al2O3 of sillimanite

brick is generally 50% ~ 60%. Its remarkable advantages are higher

volume stability at high temperature, softening point under load

and thermal shock resistance than that of high alumina brick.In

modern large melting furnace, in order to ensure the stability of

the melting furnace structure must use sillimanite brick.

Sillimanite bricks are usually fired below the temperature at which

sillimanite decomposes.In the use process, if the use temperature

is slightly lower than the sillimanite decomposition temperature,

the brick volume stability is very good, there is no obvious volume

effect;If the temperature is higher than the decomposition

temperature, sillimanite will decompose into mullite and liquid

phase, and a little volume expansion can offset the contraction

phenomenon caused by the production of liquid phase, and maintain a

relatively stable volume.

Mullite products can be obtained by high temperature firing, that

is, firing at a temperature higher than the decomposition

temperature of sillimanite and andalusite, and the volume expansion

of brick during firing can be controlled well, and the products

with superior performance can be obtained.The results show that the

microstructure of brick made by sillimanite and andalusite without

prefiring is better.This can be explained as: the pre-fired clinker

forms a mullite crystal network, which will be destroyed when

crushed, and it is impossible to form a mullite binding network

during further sintering, which will reduce the compactness and

high temperature performance of the product.

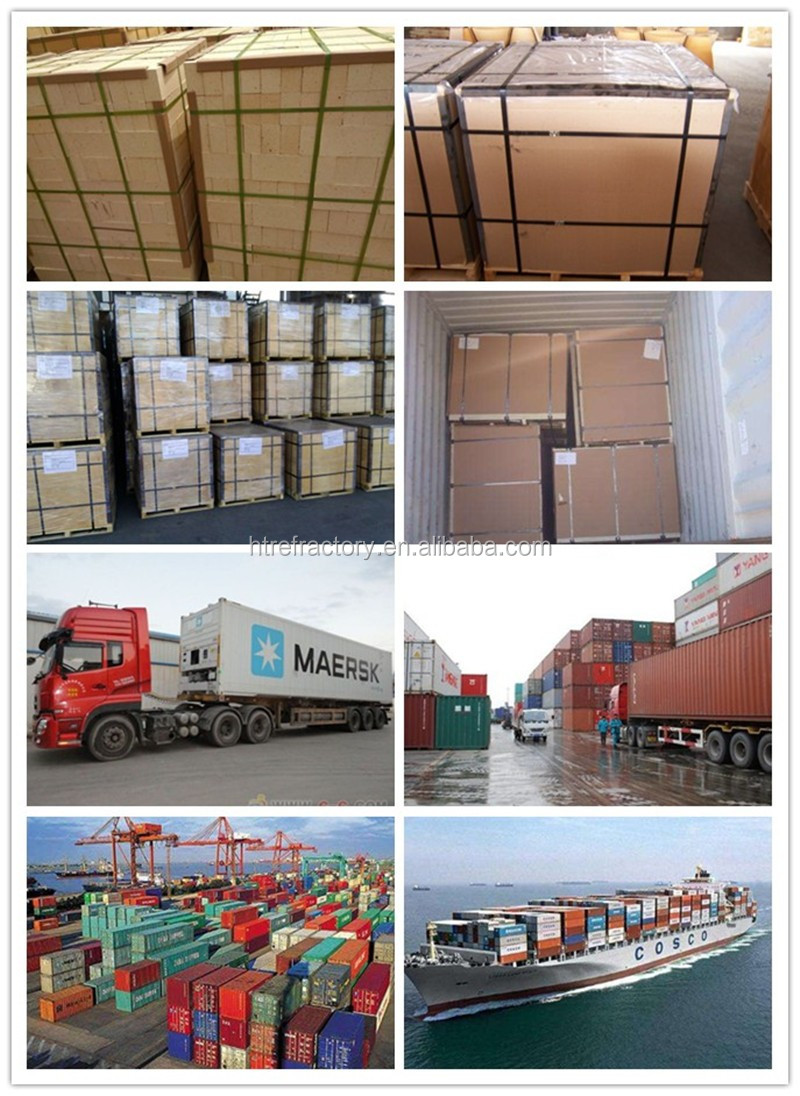

Packaging

1. 1 ton bags in container, 25 MT/20'FCL.

2. 25kg bags in container, 25 MT/20'FCL

3. 25kg bags in ton bags, then in container, 25 MT/20'FCL

4. as the customer' request

Packaging of SK37 High Alumina Refractory Brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

Shipping of SK37 High Alumina Refractory Brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quality and quantity

guaranteed, and also in accordance with the contract and customer's

requirement completely.

Delivery:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods, etc.

Your inquiry related to our product & price will be replied

within 24 hours.

Export:

Our products have been exported to many countries: Australia,

Chile, USA, Russia, UK, Indonesia, etc., good quality have be

approved by our clients.

1.Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand,quickly respond mails and provide solutions.

2.Free sample of dry ramming mass

Sample and trial order are accepted for the quality evaluation

3.Strict quality control

Arrange production on time and control quality strictly.

4.Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5.Professional Services

Provide all the detailed news and pictures from order to delivery;offer relative export documents and original certificate if needed;warm and considerable after-sale service.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our

aim."Scientific management, strong technical force, perfect testing

means, advanced technological equipment and stable product quality

are the guarantee of quality service.Henan hongtai kiln

refractories co., LTD sincerely hopes to cooperate with you hand in

hand and in good faith.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium

corundum brick, fireproof ball lightweight insulation brick,

wear-resistant pouring material, corundum pouring material, low

cement high strength pouring material, impermeable material,

self-flowing material, plastic material, and various types of

refractory materials.For different industries, the cement industry

with anti-flaking high-alumina bricks, alkali resistant bricks,

phosphate bricks;Boiler industry USES all kinds of brand

wear-resisting brick, corundum brick, mullite brick and other

finalizing materials.The company insists on "product quality is the

life, enterprise integrity is the foundation", in the fierce market

competition, won many users' trust and praise.The products are sold

all over the country, as far as Vietnam, India, Korea, Pakistan,

kazakhstan and other southeast Asian countries and regions.

Henan hongtai kiln refractory co., LTD. Is well aware that there are thousands of demands from customers, which can be summarized in four aspects: reliable quality, timely delivery, reasonable price and considerate service.The company will continue to adhere to the corporate spirit of "contributing to society and serving customers" and the business philosophy of "mutual benefit, win-win, integrity, efficiency, preciseness and responsibility".Our company is willing to develop a wide range of technical exchanges with colleges and universities and colleagues from all walks of life at home and abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement high strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.For different industries, the cement industry with anti-flaking high-alumina bricks, alkali resistant bricks, phosphate bricks; Boiler industry uses all kinds of brand wear-resisting brick, corundum brick, mullite brick and other finalizing materials.The company insists on "product quality is the life, enterprise integrity is the foundation", in the fierce market competition, won many users' trust and praise.The products are sold all over the country, as far as Vietnam, India, South Korea, Pakistan, Kazakhstan and other southeast Asian countries and regions.

Henan hongtai kiln refractory co. LTD. : "quality first, reputation first, customer first" is our aim .Scientific management, strong technical force, perfect testing means, advanced technological equipment and stable product quality are the guarantee of quality service. Henan hongtai kiln refractories co., LTD sincerely hopes to cooperate with you hand in hand and in good faith.