Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

China refractory fused cast S5 EPIC azs brick for stacks, uptakes,

side walls, bottoms and forehearths of ceramic glaze furnace

Fused Cast S5 EPIC AZS brick as an important role used in Glass Furnace is made of pure alumina powder and zircon sand and is composed of three main chemical components of Al2O3, ZrO2 and SiO2. Fused Cast AZS refractory brick is manufactured through casting technology in RS Professional Factory.

AZS refractory brick, Alumina-Zirconia-Silica (AZS) refractories,

belong to sintered ZrO2_Al2O3_SiO2 products family along with

Zircon Mullite, Bonded AZS, Zirconia Corundum, and Rebonded Fused

Mullite bricks. Sintered ZrO2-Al2O3_SiO2 products such as AZS have

good resistance to alkali vapor and thermal shock. Mainly used in

glass furnaces, they can withstand aggressive conditions in contact

with molten glass.

Fused Cast AZS Refractory bricks products of AZS series of oxidation are made of qualified raw materials by using specially designed electric arch furnace and undergoing the casting process through long-arc melting furnace and oxidation. This kind of casting process hardly suffers any carbon pollution from the electrode.

Properties Of Fused Cast S5 EPIC AZS refractory brick

Dense micro structure

Strong resistance for high temperature and glass liquid

Good thermal shock resistance

High compression resistance

Wear and slag erosion resistance

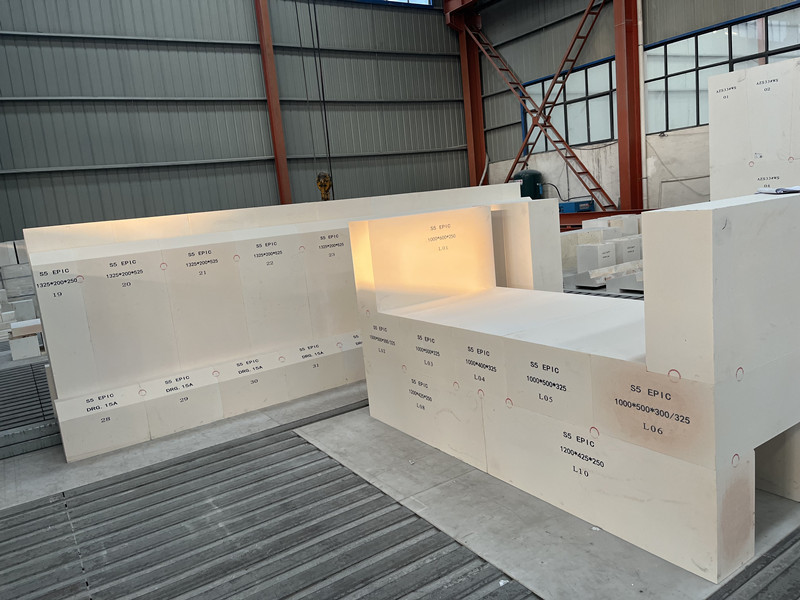

Shapes & Sizes Of Fused Cast S5 EPIC AZS refractory brick

Fused Cast AZS refractory brick can be customized to be straight or

approximate brick in a large size. Henan Hongtai can also

adopt special manufacturing process and technology to produce

special fused cast AZS Block according to your requirement for

application glass furnace.

Features Of Fused Cast S5 EPIC AZS refractory brick

1.Casted by melting raw material in the mold, then cooling and

solidification.

2.Strong glass corrosion resistance and high thermal shock

stability.

3.Good wear-resistance,slag-resistance and alkali corrosion

resistance.

4.High-purity raw material, barely no pollution.

5.Top quality, long service time.

Shapes and sizes: there are great variety of formats and shapes

which are available for different forming and special machine

processes.

China refractory fused cast S5 EPIC azs brick for stacks, uptakes, side walls, bottoms and forehearths of ceramic glaze furnace

| ITEMS | NR-AZS-41 | NR-AZS-36 | NR-AZS-33 | |

| ZrO2 (%) ≥ | 40.0-42.0 | 36.0-37.0 | 32.0-34 | |

| SiO2 (%) ≤ | 13 | 14 | 15.5 | |

| Al2O3 | ---- | ---- | ----- | |

| Na2O≤ | 1.3 | 1.4 | 1.5 | |

| Fe2O3≤ | 0.1 | 0.1 | 0.1 | |

| TiO2≤ | 0.05 | 0.05 | 0.05 | |

| B.D. (g/cm 3 ) ≥ | 4.12 | 3.89 | 3.8 | |

| C.C.S (Mpa) ≥ | 350 | 350 | 350 | |

| Bulk density(g/cm 3 ) | PT/QX | 3.55 | 3.45 | 3.4 |

| ZWS | 3.9 | 3.65 | 3.6 | |

| WS | 3.92 | 3.78 | 3.7 | |

| Apparent Porosity (%) | 1.3 | 1.5 | 2 | |

| Refractoriness ( C) | 1730 | 1710 | 1710 | |

| 0.2Mpa Softening temp. under load( C) | >1700 | >1700 | >1700 | |

| Exudation temp. of Glass Phase( C) | >1430 | >1420 | >1400 | |

| Corrosion Resistance of Glass Melt(mm/24h) | 1.1 | 1.2 | 1.3 | |

| Thermal Expansion(%), 100C | 0.8 | 0.8 | 0.8 | |

| Glass Phase (%) | 18 | 19 | 20 | |

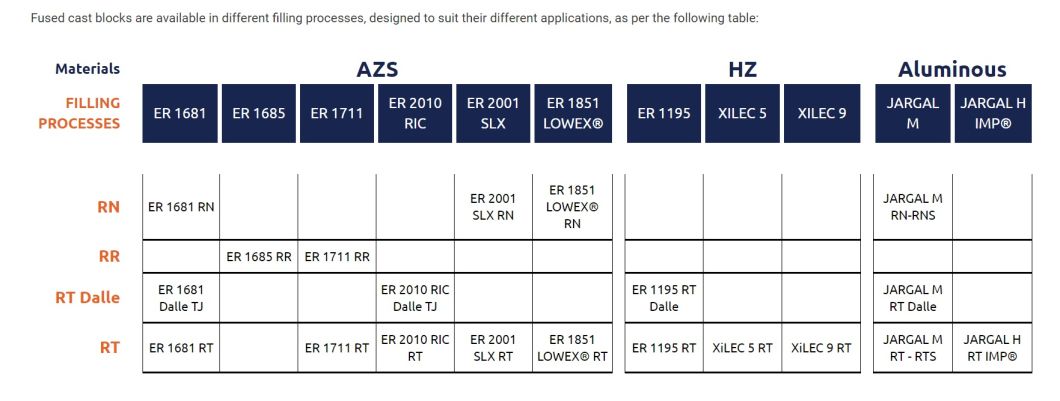

Saint-Gobain Fused Cast Equivalent Products Comparasion :

China refractory fused cast S5 EPIC azs brick for stacks, uptakes, side walls, bottoms and forehearths of ceramic glaze furnace

Manufacturing Process of S5 EPIC AZS refractory brick

There are four steps for manufacturing process of AZS refractory

brick including melting of raw materials, casting, cooling and

cutting.

Prefer proportions of 1:1 zircon sand and industrial alumina powder and add few volume of NaZO, B20 agent of fusion after mix perfectly through smelting and pouring into mould at high temperature of 1900~2000℃ resulting the fused cast brick contained 33% ZrO2 content. On the base, adopt part of desilicication zircon sand as the raw material to make the fused cast brick with 36%~41% ZrO2 content.

If the casting speed is too fast and the temperature is too high,

the air in the mold will not be exhausted and the bottom of the

mold will be broken, which will waste the casting time. So it is

very important to control the casting temperature and speed.

The quality of AZS refractory brick is subjected by the quality of

raw materials and manufacturing technology. Rongsheng Refractory as

a professional fused cast AZS refractory brick manufacturer can

provide customers with high quality AZS refractory brick at low

price based on our professional engineers, advanced technology and

equipment.

Due to the application of such casting technology and high-purity raw materials, AZS refractory brick of oxidated electrocast zirconia-alumina products are possessed of special and high quality of erosion resistance of glass liquids. In addition, it has the minimal pollution to the glass.

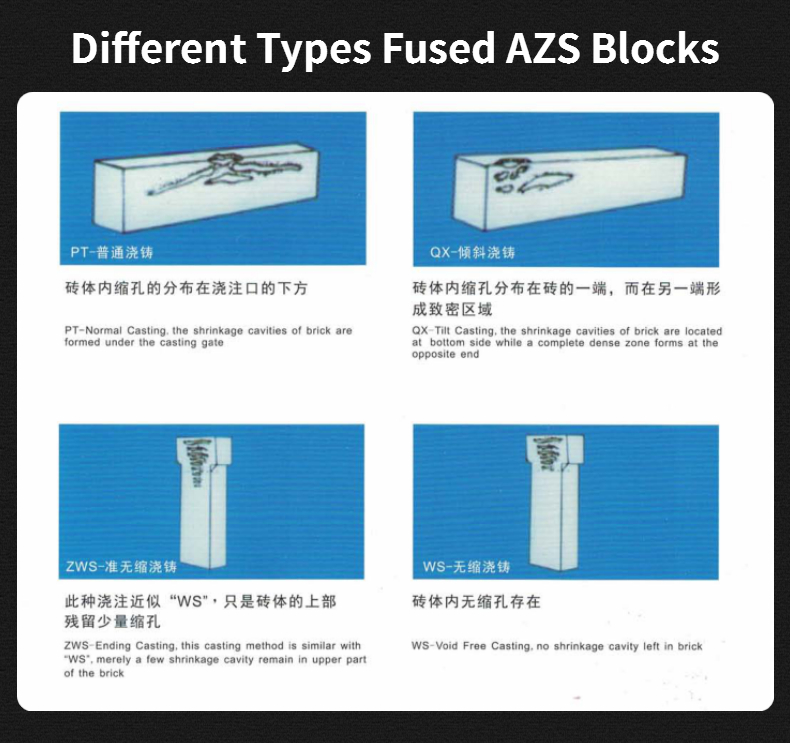

Besides, the fused cast AZS Blocks can be devied into different

types according its casting techniques, PT [normal casting], QX

[tilt casting ] , ZWS [reinforced casting ] and WS [void-free

casting].

WS while casting, the casting size is bigger than that is required.

Most of the voids concentrate in the header which is subsequently

cut off with a diamond saw, and then the block in required size is

left, most used in side wall and flow.

PT The brick made by normal casting has normal shrinkage void; it is

often used in the upper structure of furnace and the interface

parts which touch molten glass.

ZWS while casting, the casting size is bigger than it is required.

Most of the voids concentrate in the header which is subsequently

cut off with a diamond saw, and then the block in required size is

left, most used in side wall.

QX by tilt casting, shrinkage voids focus on one side, while the

other side is dense. This kind of bricks are usual sabity is

located towards the bottom, and of the block that used for

sidewalls.

Packaging of S5 EPIC Azs Refractory Brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons

Shipping for S5 EPIC AZS refractory brick

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods.

3. Customers specifying freight forwarders or negotiable shipping

methods!

4. Delivery Time:3 days for common shape samples;15 days for

special shape samples.Within 30 days for batch goods.

AZS Block Payment Terms

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance

before delivery or negotiations to solve.

2. MOQ: Usually 1Tons,Customers can order certain PCS

for corundum brick.

Henan hongtai kiln refractory co., LTD. Is well aware that there are thousands of demands from customers, which can be summarized in four aspects: reliable quality, timely delivery, reasonable price and considerate service.The company will continue to adhere to the corporate spirit of "contributing to society and serving customers" and the business philosophy of "mutual benefit, win-win, integrity, efficiency, preciseness and responsibility".Our company is willing to develop a wide range of technical exchanges with colleges and universities and colleagues from all walks of life at home and abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement high strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.For different industries, the cement industry with anti-flaking high-alumina bricks, alkali resistant bricks, phosphate bricks; Boiler industry uses all kinds of brand wear-resisting brick, corundum brick, mullite brick and other finalizing materials.The company insists on "product quality is the life, enterprise integrity is the foundation", in the fierce market competition, won many users' trust and praise.The products are sold all over the country, as far as Vietnam, India, South Korea, Pakistan, kazakhstan and other southeast Asian countries and regions.

Henan hongtai kiln refractory co. LTD. : "quality first, reputation first, customer first" is our aim .Scientific management, strong technical force, perfect testing means, advanced technological equipment and stable product quality are the guarantee of quality service. Henan hongtai kiln refractories co., LTD sincerely hopes to cooperate with you hand in hand and in good faith.

China refractory fused cast S5 EPIC azs brick for stacks, uptakes, side walls, bottoms and forehearths of ceramic glaze furnace

Q1.What is the difference between Refractoriness and Working temperature of AZS Block?

A1:Refractoriness:the AZS Block withstands high temperature without melting and softening performance in the absence of load resistance.Usually working temperature is less than refractoriness about 350-400°C.Q2.How are the AZS Block quality?

A2:White corundum fire brick will be strictly inspected before shipment, so the quality could be guaranteed.

Q3:What is the Warranty for the corundum mullite brick?

A3:For all the brick,we have 1 years warranty.If any quality problems on our side occured in this period ,we will take on the shipping cost and replacement.

Q4.What is the service life of the AZS Block?

A4:The service life of different bricks is unlike.It also depends on your using condition and method.

Q5:Are you a manufacture or trader?

A5:We are manufacture and we can supply good pre-sale service, after-sales service.

Q6.Can we visit your company?

A6:Sure,welcome at any time,seeing is believing.

Q7. Do you provide samples?

A7:Yes, samples are available.

Q8. Do you accept OEM?

A8:Yes, we can do OEM.

Q9.What's the MOQ of trial order?

A9:No limit,We can offer the best suggestions and solutions according to your condition.

Q10.What are the payment terms?

A10:Usually T/T,but L/C,Western Union etc are available for us.

Q11. How long is delivery time?

A11:The delivery time will be determined according to the quantity of the order.

Q12.How about your company's certification?

A12:ISO9001 and Test Report,also we could apply other necessary certification.