Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Silica Brick for Coke Oven or Hot Blast Stove

A brief introduction of Silica Brick

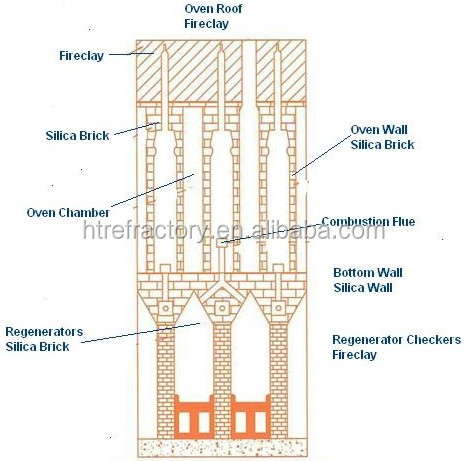

Silica Brick is a kind of acid refractory mainly made from tridymite, cristobalite and a small amount of residual quartz as well as glass phase. The raw material is natural silica sand whose SiO2 content should be more than 96%. The higher SiO2 content in silica sand, the higher temperature Silica Bricks resist. Silica Bricks are used in the roof and superstructure of glass melting tanks as well as for hot repairs.

Applications

Silica brick for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace of regenerator and a sediment chamber, soaking furnace, glass furnacerefractory brick materials and ceramic firing kiln kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Our Silica Brick advantages

--Adopts high quality silica and advanced technology, our Silica Bricks enjoy the advantages of high purity, long service life, good thermal conductivity, high refractoriness under load, and good creep resistance.

--In addition, it has accurate size tolerance, pure color and luster appearance.

--Because of the good thermal shock resistance of Silica Brick, it is mainly used in the continuous operating furnace.

--Supporting the use of other high quality refractories, our Silica Brick can extent the service life of float glass furnace to 8 years and double the service life of bottle glass furnace.

Refractory Silica Bricks Size

| Straight Type | Arch Type | Wedge Type |

| L×W×H (mm) | L×W×H/h (mm) | L×W×H/h (mm) |

| 230×114×65 | 230×114×65/55 | 230×114×65/55 |

| 230×114×75 | 230×114×65/45 | 230×114×65/45 |

| 230×114×32 | 230×114×65/59 | 220×110×75/65 |

| 220×110×60 | 220×110×65/50 | 220×110×60/40 |

| 220×110×50 | 220×110×75/65 | |

| 220×110×40 | 220×110×60/40 | |

| 220×110×30 |

Specifications Of Silica Brick

1.Higher SiO2 content of more than 96%, with true density of 2.34g/cm3, thus it has good performance in corrosion of acid slag.

2.Excellent resistance in high temperature. The melting temperature under load is 1620-1670℃. Durable, with no deformation under high temperature.

3.Good thermal shock resistance, High heat conductivity.

4.At 1450℃, there is 1.5-2.2% overall expansion which makes the joint-cutting dovetailed, thus Silica Bricks have good air tightness and strong structure.

Technical Data Of Silica Brick

| Index | High quality Silica Bricks | Silica Bricks for coke oven | |||||

| XBG-96 | ZBG-96 | DBG-96 | JG-94A | JG-94B | JG-94Y | ||

| 15Kgs | 15-25Kgs | 25-40Kgs | |||||

| Refractoriness | 1690 | 1690 | 1690 | ||||

| Apparent porosity % | 22 | 23 | 24 | 22 | 24 | 22 | |

| True density | 2.34 | 2.34 | 2.34 | 2.35 | 2.35 | 2.35 | |

| Cold crushing strength MPa | 35(30) | 35(30) | 29.4 | 29.4 | 19.6 | 29.4 | |

| Refractoriness under load 0.2Mpa ℃ | 1680 | 1680 | 1670 | 1650 | 1650 | 1650 | |

| Permanent linear change % | 0-0.3 | 0-0.3 | 0-0.3 | 0.2 | |||

| 1450 | |||||||

| Index | BG-95A | BG-95B | BG-96A | BG-96B | GZ-94 | GZ-95 | Wall of stove | Check brick | |

| Refractoriness | 1710 | 1710 | |||||||

| True density | 2.34 | 2.34 | 2.35 | 2.35 | 2.38 | 2.37 | 2.35 | 2.35 | |

| Apparent porosity % | 22(24) | 22(24) | 22(24) | 22(24) | 23 | 22 | 22 | 23 | |

| Cold crushing strength MPa | 35(30) | 35(30) | 35(30) | 35(30) | 24.5 | 29.4 | 35 | 30 | |

| Refractoriness under load 0.2Mpa ℃ | 1660 | 1650 | 1680 | 1670 | 1640 | 1650 | |||

| Melting index% ≤ | 0.7(0.7) | 0.5(0.6) | |||||||

| Creep 0.2Mpa50h % | 15500.8 | 15500.8 | |||||||

| Thermal shock resistance at 1000℃ % | 1.26 | 1.26 | |||||||

| Remain quartz % | Data must be provided | ||||||||

| Chemical | SiO2 % | 95 | 95 | 96 | 96 | 94 | 94 | 95 | 95 |

| composition | Fe2O3 % | 1 | 1 | 0.8 | 1 | ||||

Silica Brick for Coke Oven or Hot Blast Stove

Applications Of Silica Brick

The Silica Brick can be widely used in coke oven, hot blast furnace, glass furnace and carbon furnace. In glass industry, it is mainly employed to build the doghouse crown, suspended wall of channel, top crown and inlet sealing. In detail, Silica Bricks plays the following role in different fields:

--being the partition walls in coke oven carbonization and burning chamber;

--metallurgy industry: used as refractories for steel making open hearth regenerator, slag pocket, soaking pit;

--arch crown and other weight bearing areas in ceramic kilns, hot blast furnace and acid open hearth;

--worked as building checker chamber, chute, combustion chamber, coking chamber and furnace arch in glass melting furnaces.

Packing:

Standard export wooden pallet with cardboard and PET strap.

1. Strong packing will protect the goods from any possible damage

during transit.

2. Solid packing and overall stuffing can prevent the cases from

vibration and jarring.

3. We must take necessary precaution that the packing can protect

goods from pilferage or rain.

4. We can confirm that we take every possible precaution to ensure

that our products reach our customers all over the world in prime

conditon.

Shipping:

By vessel or by train from any Chinese port, Samples can be delivered by International express.

Delivery:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods, etc.

Your inquiry related to our product & price will be replied

within 24 hours.

Export:

Our products have been exported to many countries: Australia,

Chile, USA, Russia, UK, Indonesia, etc., good quality have be

approved by our clients.

Silica Brick for Coke Oven or Hot Blast Stove

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to

the chemical content,raw materials are classified into different

levels to ensure quality of Silica Brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management: inspection of product

standardization of quality of each product by process control and

experimentation, taking corrective measures timely whenever

deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance,

physical and chemical properties of Silica Brick again in factory.

Henan hongtai kiln refractory co., LTD. Is well aware that there are thousands of demands from customers, which can be summarized in four aspects: reliable quality, timely delivery, reasonable price and considerate service.The company will continue to adhere to the corporate spirit of "contributing to society and serving customers" and the business philosophy of "mutual benefit, win-win, integrity, efficiency, preciseness and responsibility".Our company is willing to develop a wide range of technical exchanges with colleges and universities and colleagues from all walks of life at home and abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our

aim."Scientific management, strong technical force, perfect testing

means, advanced technological equipment and stable product quality

are the guarantee of quality service.Henan hongtai kiln

refractories co., LTD sincerely hopes to cooperate with you hand in

hand and in good faith.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium

corundum brick, fireproof ball lightweight insulation brick,

wear-resistant pouring material, corundum pouring material, low

cement high strength pouring material, impermeable material,

self-flowing material, plastic material, and various types of

refractory materials.For different industries, the cement industry

with anti-flaking high-alumina bricks, alkali resistant bricks,

phosphate bricks;Boiler industry USES all kinds of brand

wear-resisting brick, corundum brick, mullite brick and other

finalizing materials.The company insists on "product quality is the

life, enterprise integrity is the foundation", in the fierce market

competition, won many users' trust and praise.The products are sold

all over the country, as far as Vietnam, India, Korea, Pakistan,

kazakhstan, Iran and other southeast Asian countries and regions.

The products are sold all over the country, as far as Vietnam, India, Korea, Pakistan, kazakhstan, Iran and other southeast Asian countries and regions.