Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

high thermal conductivity silica brick for glass furnace / coke oven

high thermal conductivity silica brick for glass furnace / coke oven

The silica bricks are the main fire-resistant material of coke oven. In order to keep its high quality,we use the high purety quatz with the multistage batching and best grain matching, our semi-manufactured goods are produced by the pressing machine.

The bottom,Wall and top bricks are produced by 500tons bricks pressing machine. Every semi-manufactured and finished product-s are examined according to the national standard and marked it according to the tolerance.

silica bricks are used for coke and annealing furnace, covering the walls of the furnaces, in high heat areas of melting furnaces.

Advantages of refractory silica brick:

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point with temperature.

4) No shrink in burn repeatedly.

5) Temperature of refractoriness under load is above 1650º C Stable

Capability, High Quality, Excellent Service, Competitive price is

the most important advantage of our products.

Physical & Chemical indicator of refractory silica brick:

Application of refractory silica brick:

The silica brick can be widely used in coke oven, hot blast furnace, glass furnce and carbon furnace. In glass industry, it is mainly employed to build the doghouse crown/dome, suspended wall of channel, top crown and inlet sealing. In metallurgy industry, it is adopted as the nozzle brick.

high thermal conductivity silica brick for glass furnace / coke oven

Packaging details:

1.on wooden pallets with plastic cover: wooden pallet size :930*930 or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping details:

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

Payment Item :

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance

before delivery or negotiations to solve.

2. MOQ: Usually 1Tons

3. Quality Warranty: 1 years

Delivery time :

1.Stocks:Within 5-7 days after receive the deposit.

2.Customization:Within 15-30 days after receive the deposite.

high thermal conductivity silica brick for glass furnace / coke oven

Henan Hongtai Kiln Refractory Co., Ltd. is established in 2002, located in Xinmi City, 40kilometers southwest of Zhengzhou City in Henan Province, close to Jingguang, Longhai railway lines, with road transport facilities. Rich resources of Refractory materials, adequate and qualified fuel in this area, provide unique conditions for refractory production, shipping and refractory industry development.

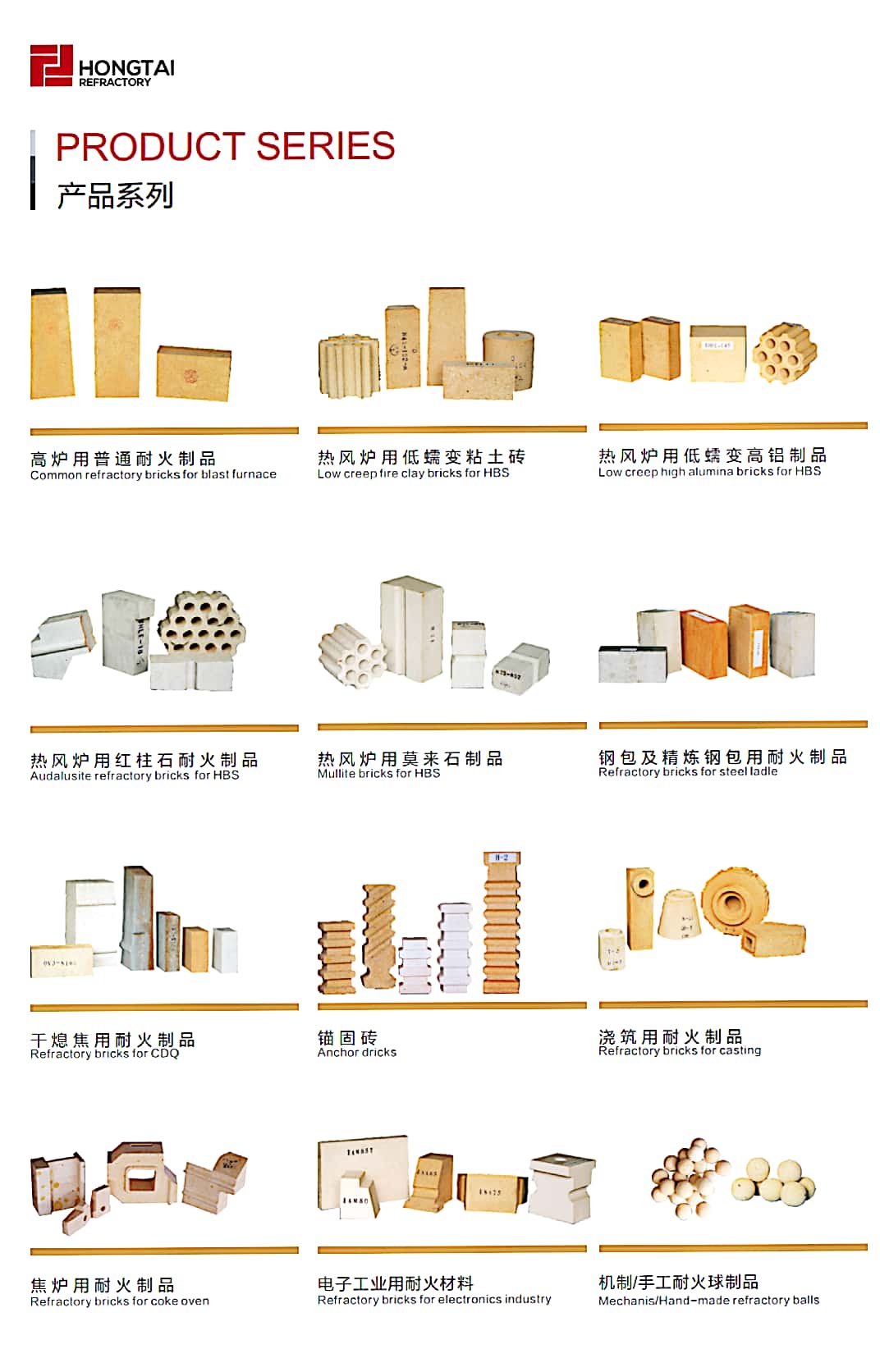

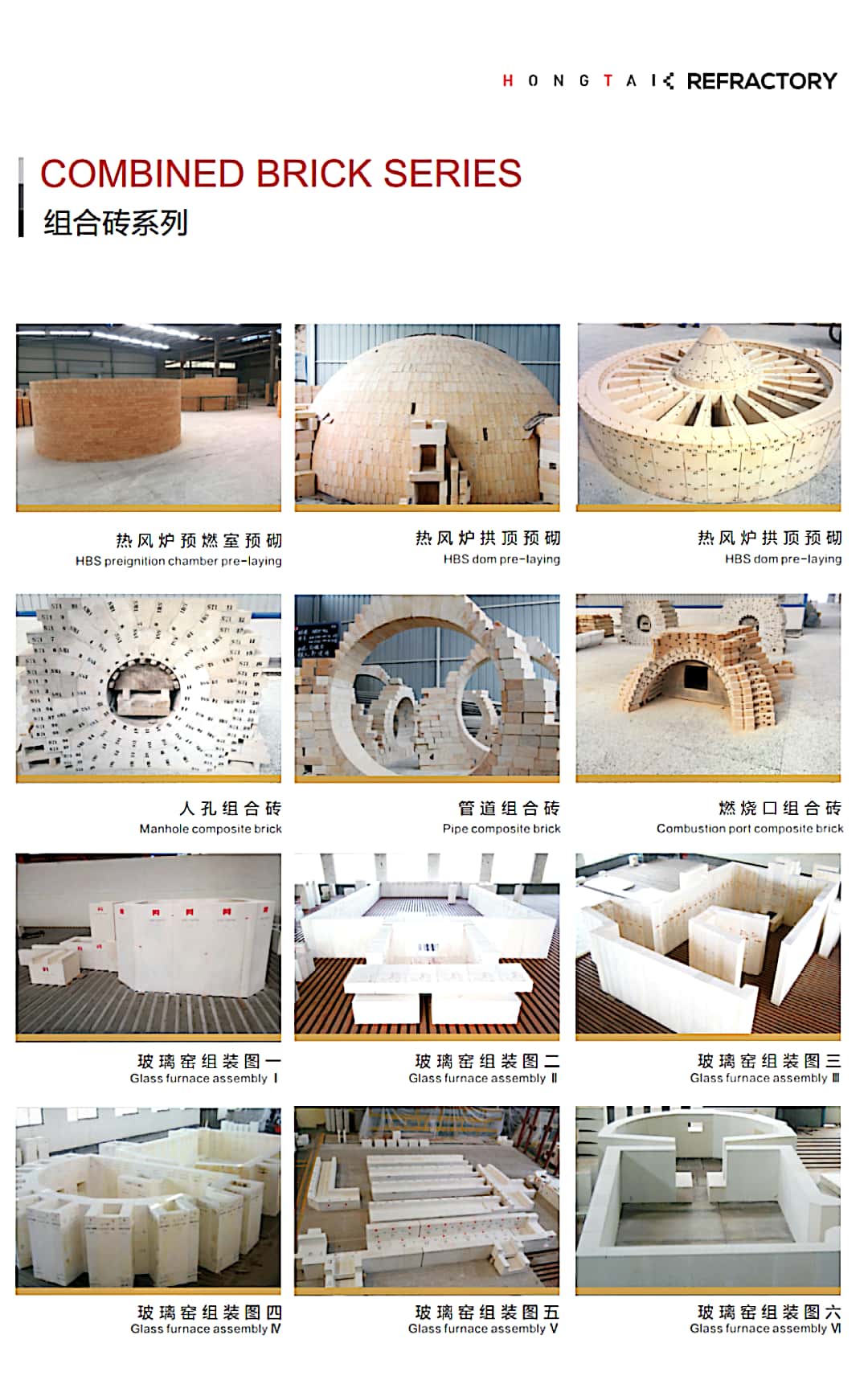

Main products include different kinds of refractory brick:Fire Clay Brick, High Alumina Brick, Light Weight Insulating Brick,Corundum Brick,Mullite Brick,AZS Bricks, Refractory Balls ,Refractory concrete,refractory castable,Acid resistant brick etc.They are widely used in Iron and steel, Nonferrous metals, Building materials(Cement,Glass,Ceramic), Petrochemical, Energy & Incineration etc industries. Our products have been exported to India,Turkey,Vietnam,Malaysia and Kazakhstan etc.“Science-Technology Innovation, Cooperation for Win-Win”

Service we can provide:

1. Quick and Positive reply after receiving your inquiry.

2. Free samples before shippment.

3. Quality control before and during shipment.

4. Loading photos as required.

5. Pompt shipment with right shipping line.

6. SGS and BV certification as required.

7. Packing according to Clients' requirement.

high thermal conductivity silica brick for glass furnace / coke oven

1.What's your payment terms?

Various payment will be supported

2.What's your delivery time?

Usually within 15-30 days after receive the deposit.

3.How about the packing?

25 kg/bag,outer woven bags with inner plastic lining.

4.What documents you provide?

Usually, we provide Commercial Invoice, Packing List, Bill of

lading, COA , TDS. etc.If your markets have any special

requirements, let us know.

5.How about the validity of the products?

According to the products you ordered.

6.What is loading port?

Usually isTianjin, Shanghai or Qingdao.

Contact person:Marina Ma

Tel:+86 18838001797

Wechat/Whats app:+86 18838001797

Viber/Telegram:+86 18838001797

Skype:Marina Ma

QQ:2262521614

Email:sales04(at)firebricks-supplies.com