Chengdu Hsinda Polymer Materials Co., Ltd. |

|

Verified Suppliers

|

|

Non Toxic Metallic Powder Coat Paint High Heat Dissipation For Mobility Wheelchairs

Application

· Powder coating can be applied to most metal components including

steel, Zinc, brass and aluminium.

· The durable finish provides a surface finish which is less prone

to chipping, marking and scratching.

· Powder coating can be applied to components used internally and

externally.

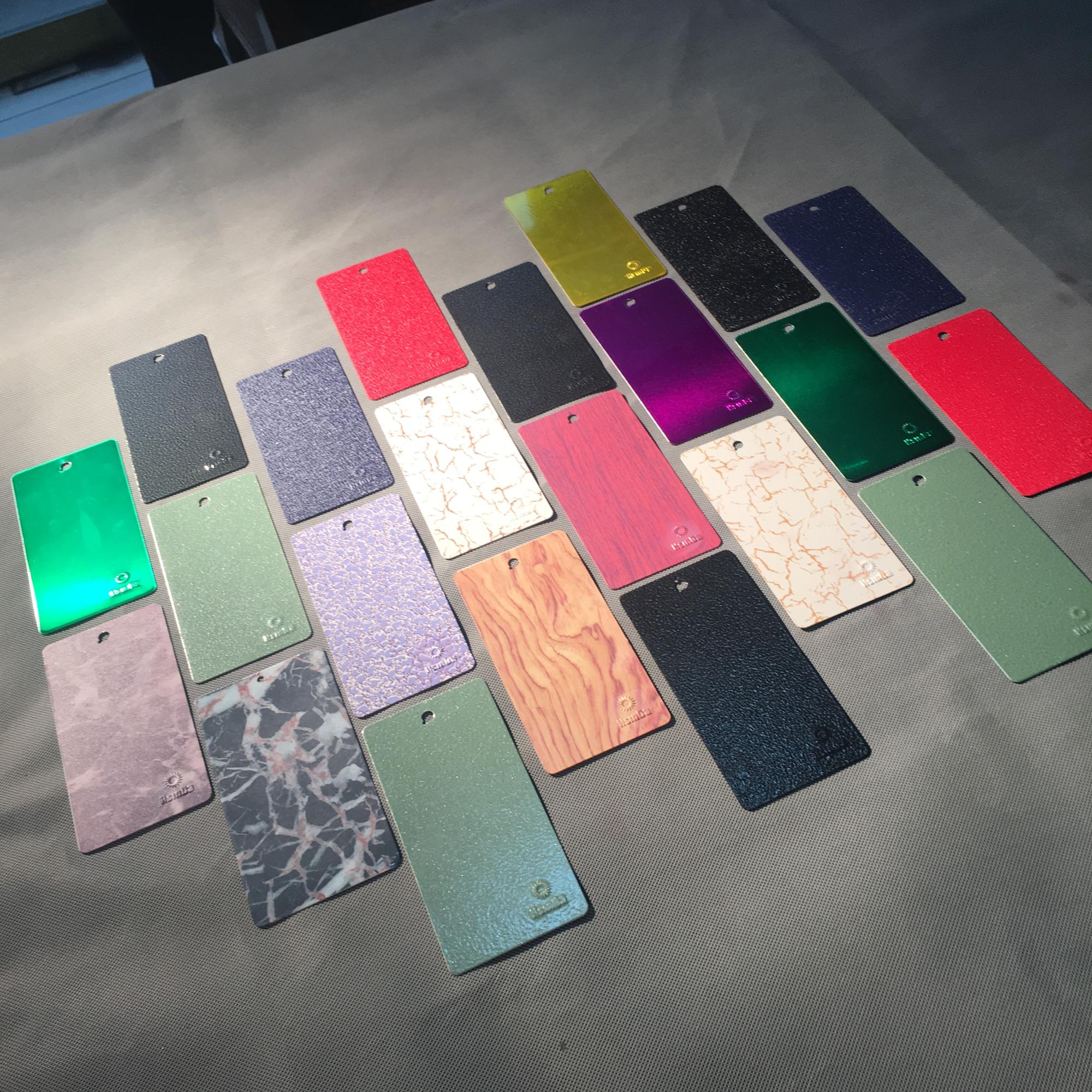

Classification of Powder Coatings

1, Functional powder coatings: powder coating of Antibacterial, Super weather resistance, Oil resistance, Dissipate heat, High temperature resistance etc.

2, Colorful powder coatings: Ral, Pantone, Customized colors

3, Special effects powder coatings: Candy, Glow in the dark, Clear top coat, Metallic, Chrome silver mirror effect, Thin coat, MDF powder coating etc.

4, Texture powder coatings: powder coating of Hammer, wood grain, water grain, crocodile skin, sand grain, wrinkle etc.

♦ Powder coatings are based on Resin,Pigments,Curing Agents,Additives.

♦ Resin(including Epoxy, polyester, hybrid)giving the basic performance to the coating.

♦ Pigments, Providing the colour and effects, such as metallic or hammer.

♦ Curing Agents, reacts with the resin to form a continuous protective film.

♦ Additives, can be used to promote variations in the performance or surface effects.

♦ Epoxy powder coating: offer the best corrosion protection.

♦ Polyester powder coating: offer the highest exterior stability and performance.

♦ Our products applied to indoor and outdoor.

♦ Our products with SGS,Tuv, Rohs, ISO Certificate.

Applications of Product

| ♦ Electrical Household Appliances | ♦ Aerospace Area |

| ♦ Automotive Electronics | ♦ Fitness Equipment |

| ♦ Track Traffic | ♦ Medical Devices |

| ♦ Petroleum Pipes, Valve | ♦ Tools & Hardware |

| ♦ LED Lights, Outdoor Lamps | ♦ Radiator & Heat Sink |

| ♦ Glass Decoration | ♦ External Facilities |

Product detail

| Test Item | Test Method | Test Result |

| Film Thickness | ISO2360 | 60-80um |

| Pencil Hardness | ASTMD 3363 | HB-H |

| Bending | ISO1519 | ≤10mm |

| Grid Test 1mm | ISO2409 | 0 Class |

| Impulse Test | ASTMD2794 | Pass |

| Cupping Test | ISO1520 | ≥8mm |

| Heat Resistance 1000 hours | ISO6270-1 | Popping<1mm |

| Salt Spray 1000 hours | ISO9227 | Corrosion Spreading<1mm |

| Trade Terms | FOB, CIF, CRF, CNF |

| Payment Terms | T/T, L/C, West Union, PayPal etc. |

| Delivery time | 3-7 days after payment |

| Packaging | Size: 39*26*43 (unit:cm) Weight: N.W. 25kg G.W. 26kg |

| Shipping | By sea, by air, by courier |

Benefits of Powder Coatings:

• Tough, durable, lasting coating for metals. Excellent hardness

and abrasion / impact resistance gives improved product performance

over most liquid coatings.

• Wide range of colors.

• Environmentally friendly outsourcing option to avoid permitting

for solvent-based paints.

• Less process variation results in consistent color and appearance

of the product.

• High film builds and excellent edge coverage gives better

resistance to corrosion with proper pretreatment.

• Coatings can be easily formulated for specific applications such

as prolonged exposure to sunlight, the ability to survive in highly

corrosive environments, flexibility to allow forming after coating,

or high durability and resistance to chipping.

We offer powder coating capabilities that include a wide spectrum of colors, thickness, textures, softness, edge coverages, flexibilities, machinabilities, smoothness and temperature ranges.

1. Wash hands before breaks and at the end of work.

2. Avoid contact with the eyes and skin.

3. Do not eat, drink, smoke or sniff while working.

4. Avoid inhaling the powder.

5. Provide for good ventilation.

6. Protection equipment for instance:

Dust mask, filter type P2, Protective gloves, Safety glasses, Light weight protective clothing.