Guangzhou Changfeng Steel Co., LTD |

|

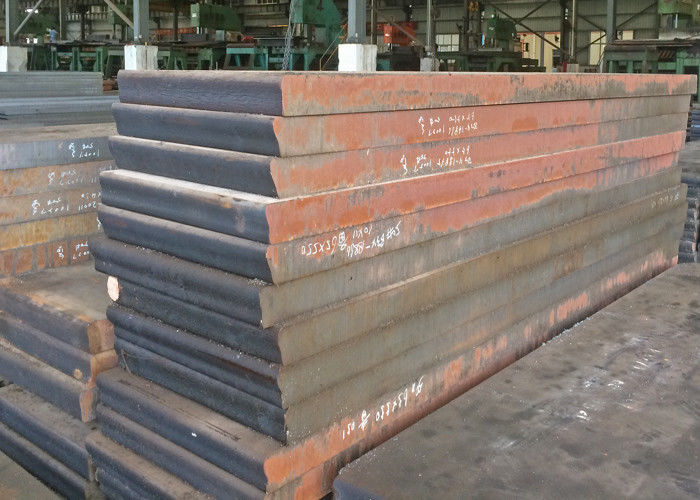

Die-casting Hot Work Tool Steel Flat Bar DIN 1.2344 Thickness 20-250mm

Introduction:

H13 / 1.2344 / SKD61 Hot Work Mould Steel is the pressure resistant hot work die steel. The electroslag remelting of the steel is of uniform material, good hardenability, excellent mechanical and polishing properties, high toughness and plasticity, good high and low temperature wear resistance, and high temperature fatigue and heat resistance.

Available size(mm):

| Flat Bar Size(mm) | Round bar Size(mm) | |||

| Thickness | Width | Length | Diameter | Length |

| 16-260 | 205-610 | 3000-6000 | 16-200 | 300-6000 |

Chemical Composition(%):

| Grade | C | Si | Mn | P | S | Cr | Mo | V |

| H13 | 0.32-0.45 | 0.80-1.20 | 0.20-0.50 | ≤0.030 | ≤0.030 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 |

| SKD61 | 0.32-0.42 | 0.80-1.20 | 0.20-0.50 | ≤0.030 | ≤0.030 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 |

| 1.2344 | 0.38-0.42 | 0.80-1.20 | 0.30-0.50 | ≤0.015 | ≤0.020 | 4.80-5.50 | 1.20-1.50 | 0.90-1.10 |

| 4Cr5MoSiV1 | 0.32-0.45 | 0.80-1.20 | 0.20-0.50 | ≤0.030 | ≤0.030 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 |

Feature:

1) Electroslag remelting steel, the steel has a high hardenability

and thermal cracking resistance, the steel contains a higher

content of carbon and vanadium, good wear resistance, toughness is

relatively weakened, with good heat resistance.

2) High temperature with good strength and hardness, high wear

resistance and toughness, excellent comprehensive mechanical

properties and high resistance to tempering stability.

3) Good resistance to high temperature tempering performance,

hardness steady working under 600℃, dimensional accuracy stability

durability.

4) Cold and hot fatigue resistance, strong ability to resist crack.

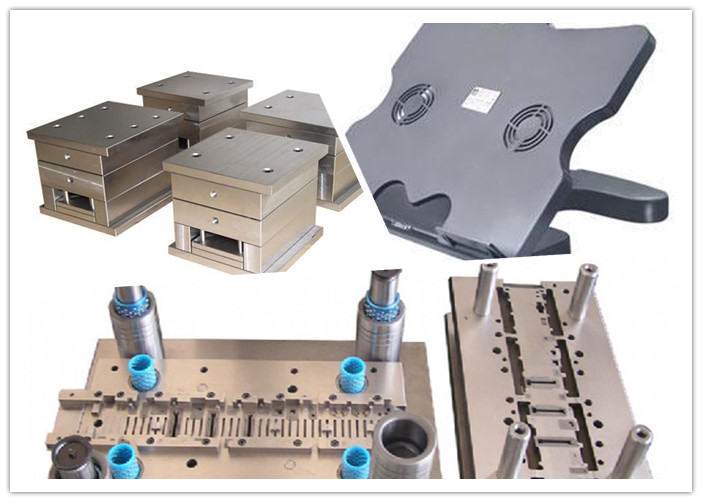

Applications:

1) Full hardness (52-54Hrc) plastiy moulds with igh polishing and

long lifetime requirements, (such as bakelite plastic mould).

2) Lead Zn and Al alloy die casting moulds (such as engine

radiater, lights ang other decoration products).

3) Aluminum extruded moulds (such as Aluminum window frame,

computer radiator).

4) Hot forging moulds (such as auto connecting rod, crank,

stainless dinner knife).

5) Cu alloy extruded, die casting moulds.

Recommend heat treatment:

| quenching | tempering | ||||||

| Heating temperature/℃ | Cooling way | Hardness (HRC) | Tempering temperature/ºC | Tempering number | Hardness (HRC) | ||

| First preheating | Second preheating | Last heating | |||||

| 500-600 | 820-860 | 1010-1040 | Oil Cooling | 53-55 | 560-620 | 2 | 50-46 |

Technical service:

Die vacuum heat treatment and die surface treatment(N-O,C-N,carburize and nitridation surface treatment).

Terms of payment:

30% deposit T/T and the balance by L/C at sight, or T/T.

Delivery condition:

For abundant stock, 15-20 days.For customized products, 30-50 days.

Our service:

1, We are the professional supplier of stainless steel welded tubes or pipes;

2, Stock always kept for small scale emergency demand;

3, Small or big order can be delivered on time per customer’s requirement.