Guangzhou Changfeng Steel Co., LTD |

|

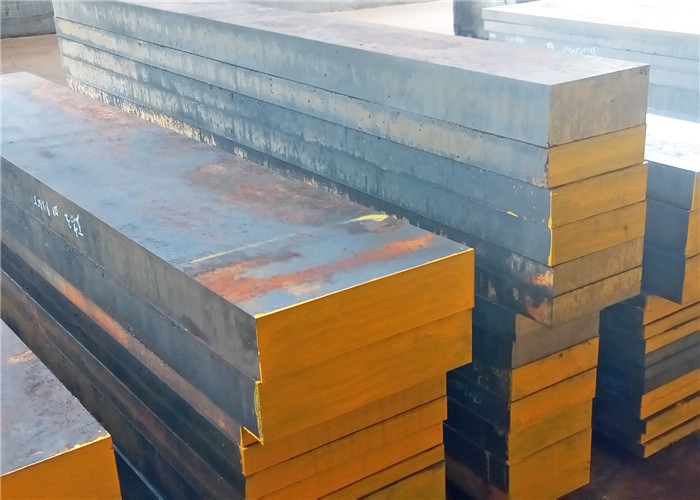

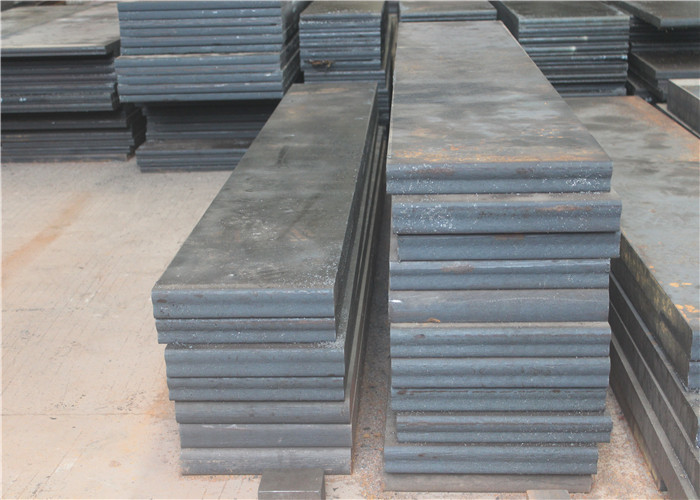

Upgraded Alloy Cold Work Tool Steels SKD1 / 1.2080 /D3

Equivalent grades

| GB | DIN | AISI | JIS |

| Cr12 | 1.2080 | D3 | SKD1 |

Chemical Composition(%)

| C | Si | Mn | Cr | Mo | Ni | Cu | P | S |

| 2.0-2.3 | ≤0.40 | ≤0.40 | 11.5-13.0 | 0.15-0.25 | 0.40-0.70 | ≤0.030 | ≤0.03 | ≤0.03 |

Recommend heat treatment

| Quenching | Tempering | ||||

| Heating temperature/℃ | Cooling way | Hardness (HRC) | Tempering temperature /ºC | Cooling way | Hardness (HRC) |

| 950-980 | Oil Cooling | 60-63 | 180-220 | Air Cooling | 60 |

| 400 | Air Cooling | 54-58 | |||

Features

D3 cold work tool steel bar is a kind of high-carbon, high chromium austenitic steel with high wear resistance, hardenability, toughness, thermal stability, compressive strength, micro-deformation and other characteristics.

D3 tool steel bar is a comprehensive performance, with good machinability and thermal oxidation resistance of cold die steel.

Wide adaptability, high wear resistance, three to four times higher than the average low alloy tool steel, dimensional stability after quenching good.

Typical applications

1. Mainly used as silicon steel die, for small dynamic load conditions require high wear resistance, simple shape drawing and blanking die.

2. For the manufacture of bending mode requires high wear-resistant, complex shape of the punch, die, insert, do punch, die when the proposed hardness of 60 ~ 64HCR.

3. For the production of drawing die wear-resistant die, the proposed hardness 62 ~ 64HCR.

4. For cold extrusion die punch aluminum, the proposed hardness of 60 ~ 62HCR.

5. For bending the carbon content of 0.65% ~ 0.80% of the bomb construction steel, hardness 60 ~ 62HCR.

6. Can be used for blanking die, punch, rolling wheel, scissors, cold pier mold, clay mold.

7. Can be used for thermosetting plastic molding and so on.

Delivery condition

EF or ESR, hot rolled or forged, black surface or milling.

Hardness: annealed, HB217-269

About us

Guangzhou Changfeng Steel Co., Ltd is a mould steel stockist, we have our own factory and trading company. Our main steels are carbon tool steel, plastic mold steel, hot work tool steel, cold work tool steel, alloy steel for mechanical, etc. All material are with high quality and competitive price.

We have different grades steel with different sizes in stocks all the time, shipment can be arranged fast. For customize items, we can also arranged the shipment within 30-50 days after receiving your prepayment or firm order.

We are here waiting for a cooperation chance between us, contact us and you will have one more loyal mold steel supplier!