Suzhou Ellison Packing Machinery CO., LTD |

|

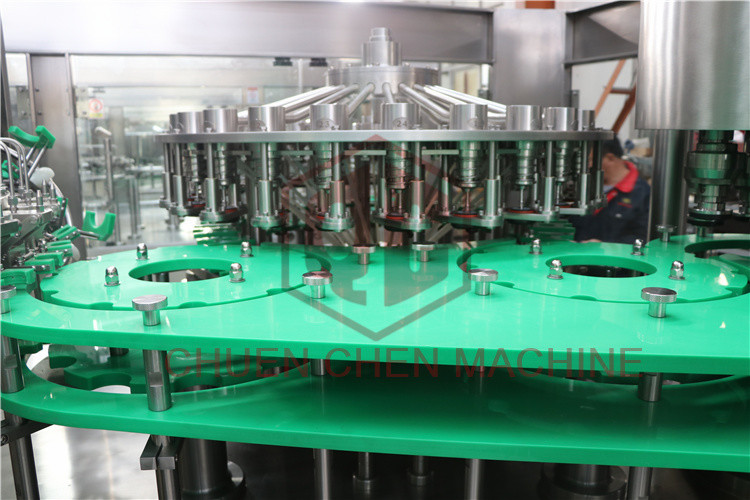

Automatic Juice Glass Bottle Filling Machine Twist Off Metal Caps

Machine description

The RGCF serious filling machine is used to fill Juice and

non-carbonated liquid into plastic bottle, glass bottles and

aluminum can. Please note that plastic bottle, glass bottle and

aluminum can can not adopt in same filling machine.

The filling machine is customized basing on the production capacity

per hour, filling liquid, bottle types and caps. Different liquid,

bottles and caps are different, the filling valve, filling nozzle,

bottle carry system are totally different.

The complete solution of juice production line includes:

1, Water treatment system

2, Juice processing line

3, Juice filling machine

4, Bottled juice pasteurizer

5, Bottled drink packing machine

General info

| Machine type | Monoblock Washing - filling - capping equipment |

| Filling liquid | Juice and non-carbonated liquid |

| Beverage type | Hot liquid |

| Capacity | 0 - 6000BPH / Customized basing on the requirement |

| Filling temperature | around 85-90 degrees celsius |

| Filling pressure | Gravity |

| Filling range | Glass bottle 500ml |

| Cap type | Twist off caps |

Auxiliary machines for filling machine

1, Liquid nitrogen injection machine

2, Cap elevator

3, Cap sorting machine

4, Online cap washing tunnel

5, Bottled juice pasteurizer tunnel

6, Option: air filter device

Characters

| Washing-Filling-Capping part | Washing unit |

Filling unit | |

Capping unit | |

| Conveyor system | Belt conveyor system |

Air conveyor system |

Technical specification

| Model | RCGF 24-24-8 |

| Capacity | 6000 BPH for 500ml bottle |

| Suitable bottle | Glass bottle |

| Bottle neck | Must be kept the same |

| Filling liquid | Juice and non-carbonated drink |

| Filling temperature | Around 85-90 degrees Celsius |

| Filling pressure | Gravity filling |

| Washing head | 24 |

| Filling head | 24 |

| Capping head | 8 |

| Air consumption | 0.5CBM / min |

| Air pressure | 6 bar |

| Total power | 5 kw |

| Voltage | 380V 3phase 50HZ / Customize |

How to get quotation?

Please write to us with below information for getting detailed

quotation sheet quickly:

- What is the filling material;

- What is your bottle type and cap type;

- How many bottle types that you have;

- How many bottles per hour you will produce;

FAQ

Q: Do you provide customized service

A: We can design the machines according your requirements(materil

,power,filling type,the kinds of the bottles,and so on),at the same

time we will give you our professional suggestion,as you know,we

have been in this industry for many years.

Q: What's your guarantee or the warranty of the quality if we buy

your machines?

A: We offer you high quality machines with 1 year guarantee and

supply life-long technical support.

Q: How long time for installation?

A: According your machines order, we will send one or two engineers

to your plant,it will take about 10 days to 25 days.

Detailed photo for ref

PLS CONTACT ME IF YOU NEED ANY HELP AND ANY DOUBT. WARMLY WELCOME

TO US.

CONTACT: VICKIE SUN

MOB (WHATSAPP): 0086 13584426100

SKYPE: vickiesunqiu

EMAIL: sunpiu2012@gmail.com