CHENGDU ZK SEPARATION TECHNOLOGY CO., LTD. |

|

High Capacity Food Processing Centrifuge For Kitchen Food Waste Disposal

Our company specialize in the design of petroleum, chemical engineering, coal chemical industry, steel, food, resin, fermentation, medicine, excess sludge of water supply and drainage, etc., completing the R&D, manufacturing and sales of dozens of products and auxiliary equipment including the solid-liquid two-phase, liquid-liquid-solid, solid-liquid-solid three-phase with different parameters explosion-proof centrifuge with flammable and explosive liquids as medium and the online real-time centrifuge with adjustable liquid layer.

We have various unique techniques such as high-efficiency sewage concentration, dehydration treatment, three-phase separation of crude oil, kitchen waste, sludge and medical extract, wear-resistant energy-saving, explosion-proof sealing and interlock control. Our centrifuge has distinctive advantages including small covering area, simple process pipeline; high degree of automation; high safety protection measures; good on-site operating environment; strong material adaptability; and stable and reliable operation.

Centrifuge Features:

★ High performance stainless steel

After the high temperature hydrolysis of the kitchen waste slurry, due to finer solid particles and 0.1-0.08 g/cm3 liquid density difference (compared with oil and water), the centrifuge needs a separation factor of more than 3000G to achieve the best separation effect. Model SAF2205 with high strength and corrosion resistance is adopted to ensure the stability and service life of the centrifuge.

★ High-dryness screw conveyor and drum structure

The dehydration of solid particles relies mainly on strong centrifugal force, high-torque screw extrusion force (pushing torque), and ultra-long solid particle dehydration length. The [ZK Separation] centrifuge can generate centrifugal force exceeding 3000G, 30 ~ 50% higher than the screw pushing torque of common centrifuges. The screw pusher torque, and the drum dehydration length is 10 ~ 20% longer than that of common centrifuges.

★ High torque involute planetary gear differential

The ultra-high-precision torque box is based on the high-torque involute planetary gear differential. The differentials equipped for the [ZK Separation] centrifuge have high torque, high speed, low heat generation and excellent heat loss. To ensure long-term, stable operation of the centrifuge.

★ CIP washing system

The fully automatic control system is equipped with a CIP washing system, which can effectively solve the problem that it is not completely cleaned during the shutdown process and effectively avoid the equipment troubles caused by artificial factors.

Good adaptability

The main part receives design optimization in exclusiveness and adjustability, fully considering all special requirements of centrifuge for material and process. The most applicable model can be provided for customers according to their materials.

High automation level

Procedures of the centrifuge such as material feeding, separation and material unloading are all automatically carried out in a continuous way during operation. The programmable logic controller is applied to realize the automatic control of centrifugal separation and automatic flushing.

Good corrosion resistance

All parts of the centrifuge that would be in contact with material are made of high-quality stainless steel. Drum and helical components of the centrifuge can be welded by 304/316/316L stainless steel, hastelloy, and titanium material, or be made by centrifugal casting using 304 stainless steel, 2205 stainless steel, etc. Multiple advanced abrasion proofing technologies are applied to protecting the helical blade and the material unloading part of drum, such as tungsten carbide coating, tungsten carbide bead welding, cemented carbide insert, and cemented carbide bushing, highly increasing the service life of the whole machine.

Safe and reliable

The centrifuge is equipped with multiple protections such as overcurrent control, vibration protection and temperature protection, to ensure safety and reliability during operation.

Beautiful appearance

The machine employs the structure of profile welding, and has a smooth and flat surface, and a beautiful appearance.

★ Three-phase centrifuge model and technical parameters

| tem | Unit | LWS250×1025C(X) | LWS350×1435C(X) | LWS450×1845C(X) | LWS520×2150C(X) | LWS580×2400C(X) | LWS650×2600C(X) |

Throughput | m3/h | ≥1 | ≥3~5 | ≥5-10 | ≥10-15 | ≥15-20 | ≥20-30 |

Roller diameter | mm | 250 | 350 | 450 | 520 | 580 | 650 |

Length-to-diameter ratio | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4 | |

Speed | rpm | 5000 | 4000 | 3500 | 3200 | 3000 | 2800 |

Separation factor | 3500 | 3136 | 3087 | 2982 | 2948 | 2854 | |

Differential speed | rpm | 1~50 | 1~35 | 1~34 | 1〜34 | 1~30 | 1~28 |

Main motor power | kW | 11 | 22 | 30 | 45 | 55/75 | 75/90 |

Ancillary motor power (kW) | kW | 4 | 5.5 | 7.5 | 15 | 18.5 | 22 |

Weight | kg | 1250 | 2500 | 4000 | 5200 | 6500 | 8000 |

Boundary dimension (L x W x H) | mm | 2500×800×1150 | 3700×1050×1400 | 3800×1150×1600 | 4800×1250×1800 | 5300×1750×1382 | 5600×1850×1500 |

Note: The throughput is related to material characteristics.

X" indicates that the heavy phase liquid is discharged by the centripetal pump with back pressure; the overall dimensions vary with the liquid discharging way of the centrifuge.

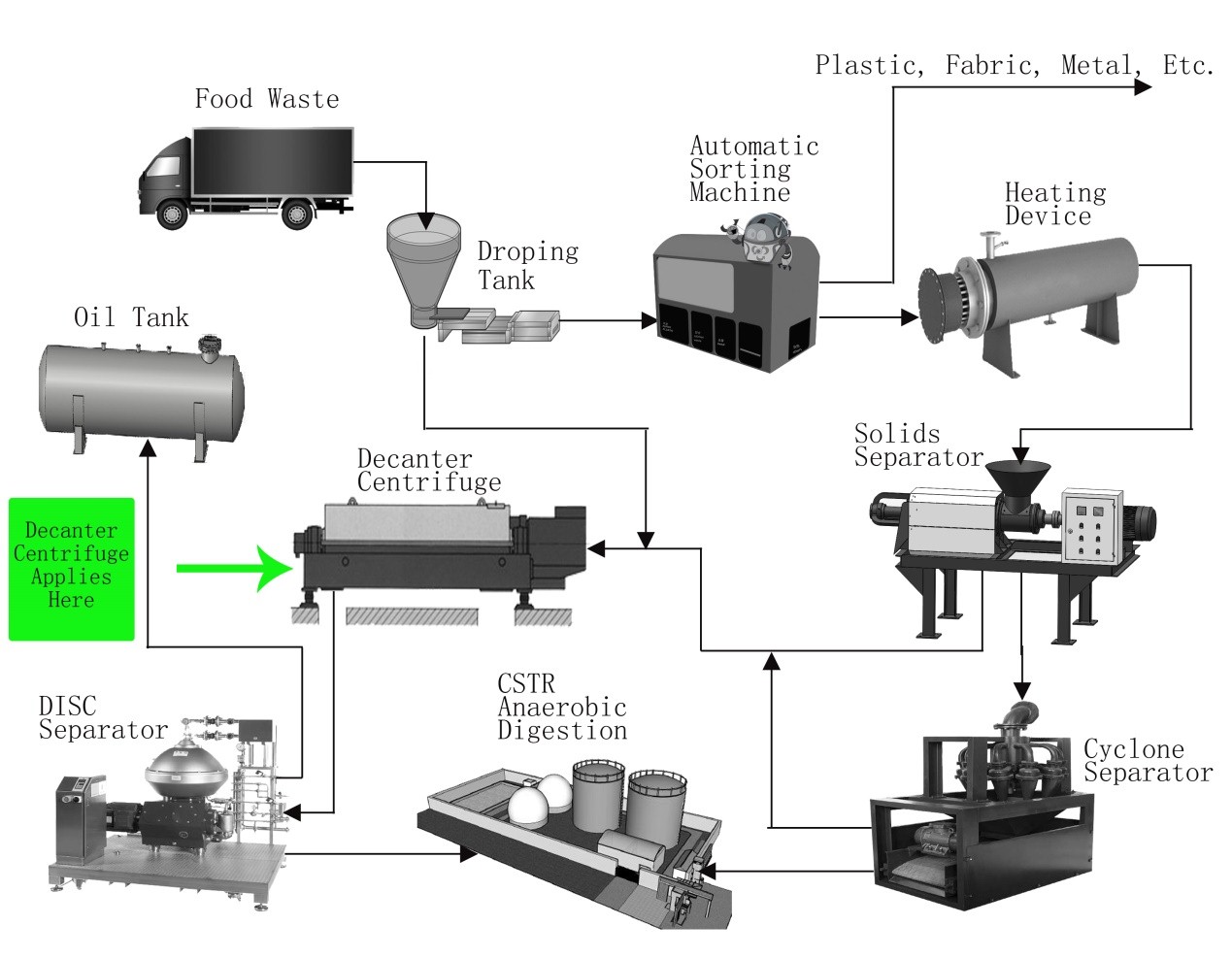

IV. Kitchen wastes water treatment system

Kitchen wastes commonly known as hogwash and also swill and pigwash, as well as wastes (residues) from food processing and edible residue residues, are complicated in composition, mainly oil, water, peels, vegetables, cooked rice and noodles, fish, meat, bones, and a mixture of waste utensils, plastics, paper towels, and the like. In respect to chemical composition, there are starch, cellulose, protein, lipids, and inorganic salt.

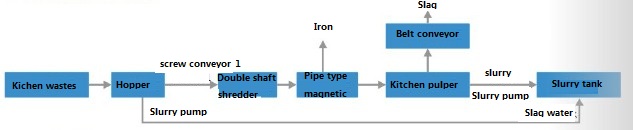

I. Kitchen wastes pretreatment system

II. Kitchen wastes deoiling system

The kitchen wastes after sorting, crushing, pulping, heating, and three-phase separation in the centrifuge are as follows:

S/N | Name | Parameter | Remarks |

| 01 | Solid phase (waste residue) solid content % (W/W) | ≥20-25 | Related to regional eating habits |

| 02 | Light liquid phase (crude oil) water content % (W/W) | ≤3~5 | |

| 03 | Heavy liquid (kitchen water) solid content % (W/W) | ≤1~2 | |

| 04 | Heavy liquid phase (kitchen water) oil content | No macroscopic oil | |

| 05 | Oil recovery rate % | ≥95 |

★ 2phase Centrifuge model and technical paramete

| Centrifuge model | mm Drum diameter mm | Length-to-diameter ratio | rpm Speed rpm | Separation factor | rpm Differential speed rpm | kW Main motor power kW | kW Ancillary motor power (kW) | m3/h Throughput m3/h | kg Weight (kg) | mm Boundary dimension: (L x W x H) |

| LW250x1025C | 250 | 4.1 | 4500 | 2835 | 1~50 | 11 | 4 | 2~5 | 1250 | 2500×800×1150 |

| LW350x1435C | 350 | 4.1 | 3500 | 2435 | 1~35 | 15-22 | 5.5 | 5〜10 | 2500 | 3700×1050×1200 |

| LW450x1845C | 450 | 4.1 | 3200 | 2580 | 1~34 | 30-37 | 7.5-11 | 8~15 | 4200 | 4300×1150×1450 |

| LW520x2150C | 520 | 4.1 | 3000 | 2620 | 1~34 | 55-75 | 11-15 | 15-25 | 5200 | 5100×1250×1600 |

| LW580x2400C | 580 | 4.1 | 2800 | 2546 | 1~30 | 75-90 | 15-18.5 | 20-35 | 6500 | 5520×1450×1700 |

| LW650x2600C | 650 | 4 | 2600 | 2460 | 1~28 | 90-110 | 22 | 35-45 | 7800 | 6250×2000×1550 |

| LW750x2800C | 750 | 3.7 | 2200 | 2033 | 1~28 | 110-160 | 30 | 40-60 | 11000 | 6500×2200×1600 |

The length dimension varies with motor power.