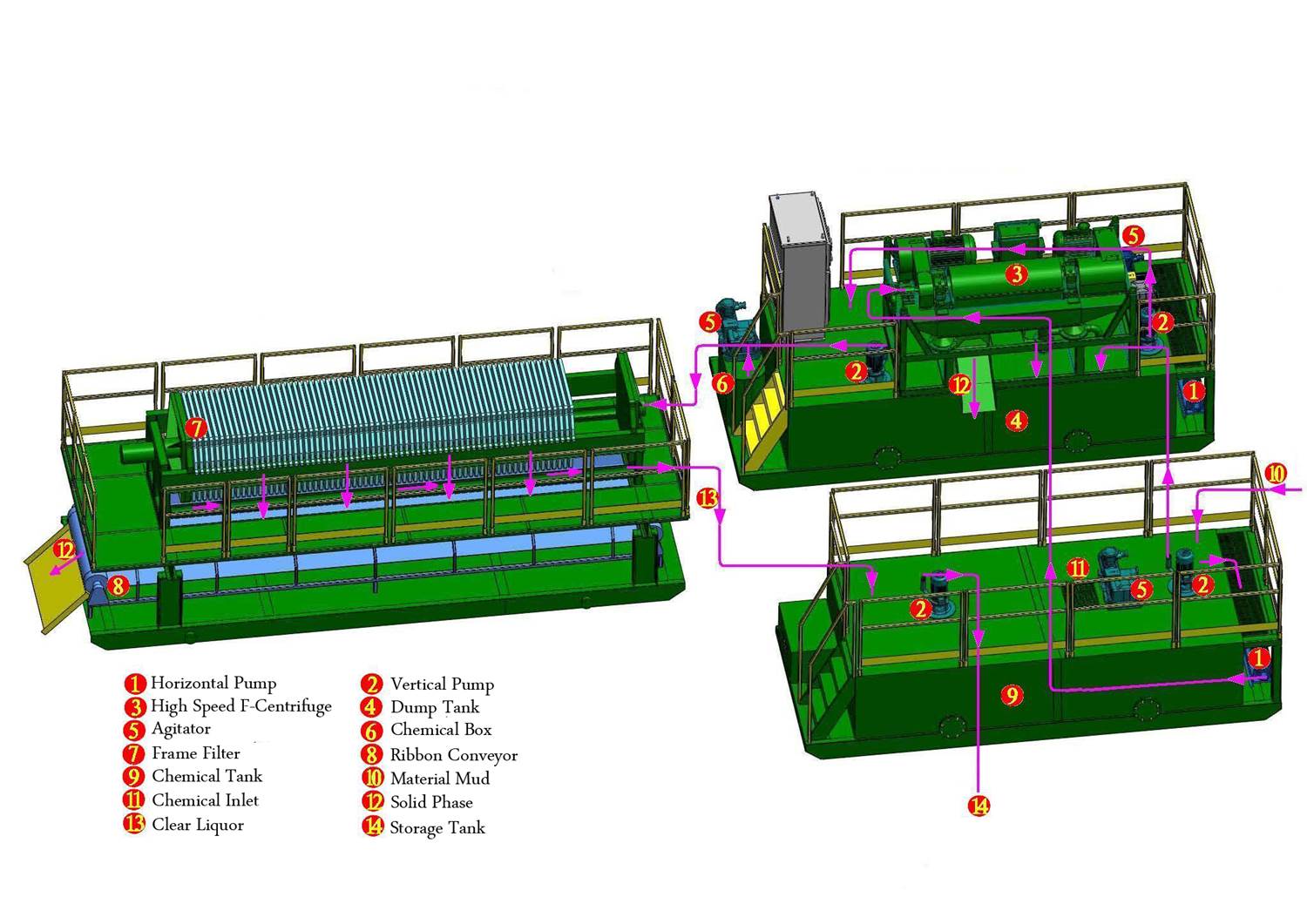

The water-based mud closed-loop treatment system is a collection of

cuttings, transmission, dosing, molding, gel breaking, solid-liquid

separation and other technical means, the cuttings discharged from

the solid control system during drilling and the drilling fluid

after drilling Collecting and processing to realize a system that

does not fall into the ground and is harmless. The system is mainly

composed of two parts: the cuttings processing system and the mud

processing system.

The system aims to process the water-based drilling fluid and

cuttings in the drilling process in real time to achieve the clean

production requirements of “the mud does not fall to the ground”.

★ Two-phase centrifuge model and technical parameters

Item |

Unit | LW250×1025B | LW350×1435B | LW450×1845B | LW520×2150B | LW580×2400B |

Throughput | m3/h | 0.5-3 | 3~10 | 8~15 | 15-20 | 20-30 |

Roller diameter | mm | 250 | 350 | 450 | 520 | 580 |

Length-to-diameter ratio | | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 |

Speed | rpm | 5000 | 4000 | 3200 | 3000 | 2800 |

Separation factor | | 3500 | 3136 | 2580 | 2620 | 2546 |

Differential speed | rpm | 1~50 | 1~35 | 1~34 | 1~34 | 1~36 |

Main motor power | kW | 11 | 22 | 30-37 | 45-55 | 75-90 |

Ancillary motor power (kW) | kW | 4 | 5.5 | 7.5 | 15 | 18.5 |

Weight | kg | 1250 | 2500 | 4200 | 5200 | 6500 |

Boundary dimension (L*W*H) | mm | 2500×800×1150 | 3700×1050×1200 | 4300×1150×1450 | 5100×1250×1600 | 5520×1450×1700 |

| Note: The throughput is related to material characteristics. |

After the system treatment, the cuttings become the expected

blocks; the drilling fluid is effectively purified or separated by

pressure filtration, and returned to the solid control system for

reuse or into the clear water tank as well production water. The

system mainly includes 7 functional units: drying sieve unit,

high-speed centrifuge unit, filter press dewatering unit, molding

machine unit, material transfer unit, dosing device, stirring

curing unit

Technical descriptions of the centrifuge

★ Extremely low infrastructure investment and good on-site operating

environment

Compared with the conventional filter-type equipment

(plate-and-frame filter, belt machine, etc.), the high-performance

centrifuge is compact and efficient, covering only about a third of

land, needless of auxiliary gas source, high-pressure water, and

with simpler pipe structures at the inlet and outlet. Moreover, the

operation environment is more humanized, and the skid-mounted

integrated device has the characteristics of compact structure,

convenient installation, low requirements for infrastructure, and

convenient movement. The centrifuge is widely used in the harmless

treatment of oily sludge in oilfield drilling.

★ Stable operation, low failure rate, and low maintenance cost

Compared with the filter type equipment, the centrifuge does not

require any filter cloth or filter screen, so as to avoid the

trouble of clogging and of replacing the filter cloth. The

operation and maintenance costs of the equipment are low.

★ Modular design, easy to operate

Our design philosophy: To lower the requirements on the skills,

educational level, and labor intensity of operators, and realize

one-button start and stop of the control system, fault

self-diagnosis, and safety self-protection.

★ Operator configuration and labor intensity

The high-performance centrifuge is an automatic and continuous

working mode for feeding-separating-slag (liquid) discharging. The

whole process requires no human intervention. Multiple sets of

equipment require only one inspector (in conjunction with other

positions). Unlike frame and plate-and-frame filter, the slag

discharging process does not require manual cutting, greatly

reducing the labor intensity of the operator.

★ Ingenious, unique, and diversified heavy liquid-phase discharging

structure

The heavy liquid phase separated by the three-phase centrifuge can

adopt two different liquid discharging modes, namely gravity

discharging and discharging through the built-in centripetal pump

with pressure, wherein the latter includes liquid layer fixed mode

and the online adjustable mode of heavy phase liquid layer, which

is selected according to the process conditions.

★ High performance wear-and corrosion-resistant cemented carbide

As the oily sludge contains a lot of hard particles and impurities

such as sand, glass, and metal, if the centrifuge does not adopt

reliable wear-resistant configuration, its service life and running

stability will be seriously affected. The wear-resistant solution

is completely targeted. According to the material characteristics

(pH value, corrosive substance, solid particle size hardness,

etc.), cemented carbide or ceramic can be selected, and the

cemented carbide can be either YG6, YG8, or various modified

tungsten-cobalt alloys with the hardness of 89~93 (HRA), which can

fully meet the application fields of the centrifuge.

★ High performance stainless steel

The high-performance three-phase centrifuge can recover oil by

90%~95% and adapts to the liquid density difference (oil and water

comparison) of the gas and oil of different densities (0.1~0.08

g/cm3). The centrifuge needs more than 3000G separation factor to

achieve better separation. To ensure the stability and the service

life of the centrifuge, high-strength corrosion-resistant duplex

stainless steel SAF2205 is used.

★ High-dryness screw conveyor and drum structure

The dehydration of solid particles relies mainly on strong

centrifugal force, high-torque screw extrusion force (pushing

torque), and ultra-long solid particle dehydration length. The

centrifuge can generate centrifugal force exceeding 3000G, 30 ~ 50%

higher than the screw pushing torque of common centrifuges. The

screw pusher torque, and the drum dehydration length is 10 ~ 20%

longer than that of common centrifuges.

★ High torque involute planetary gear differential

The ultra-high pushing torque requires a high-torque involute

planetary gear differential as the foundation. The differential

equipped on the centrifuge features high torque, high speed, low

heat generation, and excellent heat dispersion, which ensure that

the centrifuge can be used for a long time and stably.