CHENGDU ZK SEPARATION TECHNOLOGY CO., LTD. |

|

High Performance Solid Liquid Separation Machine with SS304 And SS316 Materials

Kitchen wastes commonly known as hogwash and also swill and pigwash, as well as wastes (residues) from food processing and edible residue residues, are complicated in composition, mainly oil, water, peels, vegetables, cooked rice and noodles, fish, meat, bones, and a mixture of waste utensils, plastics, paper towels, and the like. In respect to chemical composition, there are starch, cellulose, protein, lipids, and inorganic salt.

★ Three-phase centrifuge model and technical parameters

| tem | Unit | LWS250×1025C(X) | LWS350×1435C(X) | LWS450×1845C(X) | LWS520×2150C(X) | LWS580×2400C(X) | LWS650×2600C(X) |

Throughput | m3/h | ≥1 | ≥3~5 | ≥5-10 | ≥10-15 | ≥15-20 | ≥20-30 |

Roller diameter | mm | 250 | 350 | 450 | 520 | 580 | 650 |

Length-to-diameter ratio | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4 | |

Speed | rpm | 5000 | 4000 | 3500 | 3200 | 3000 | 2800 |

Separation factor | 3500 | 3136 | 3087 | 2982 | 2948 | 2854 | |

Differential speed | rpm | 1~50 | 1~35 | 1~34 | 1〜34 | 1~30 | 1~28 |

Main motor power | kW | 11 | 22 | 30 | 45 | 55/75 | 75/90 |

Ancillary motor power (kW) | kW | 4 | 5.5 | 7.5 | 15 | 18.5 | 22 |

Weight | kg | 1250 | 2500 | 4000 | 5200 | 6500 | 8000 |

Boundary dimension (L x W x H) | mm | 2500×800×1150 | 3700×1050×1400 | 3800×1150×1600 | 4800×1250×1800 | 5300×1750×1382 | 5600×1850×1500 |

Note: The throughput is related to material characteristics.

X" indicates that the heavy phase liquid is discharged by the centripetal pump with back pressure; the overall dimensions vary with the liquid discharging way of the centrifuge.

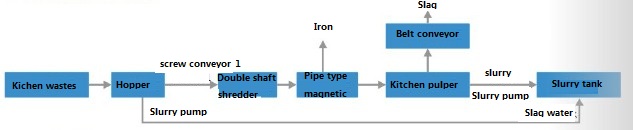

I. Kitchen wastes pretreatment system

★ Technical features:

1. With a wide range of applications and strong compatibility, it can handle all kinds of organic wastes, including kitchen wastes, rubbishes after dining, vegetable market wastes, and agriculture and forestry wastes.

2. With patented multi-stage crushing technology, it can achieve 100% crushing and utilization of organic matters to avoiding waste, enhance utilization of organic matters, and improve economic benefits.

3. With patented flexible limit crushing technology, it can realize the maximum separation of inorganic substances to avoid the inorganic substances from mixing with the organic slurry and prevent the inorganic substances from affecting the treatment effect of subsequent process, and to protect the normal operation of subsequent processing equipment.

4. The treatment process is safe and environmentally friendly, and free of pollution discharge such as wastewater and waste gas. The wastewater can be recycled after treatment, which is economical and energy-saving.

Our pretreatment system consists of a stainless-steel storage and feeding system, a double-shaft shredder, a screw conveyor, a pipe-type magnetic separator, a kitchen pulper, a belt conveyor, a slurry tank, a transfer pump, pipes, detection instruments, etc.;

The collected swill is poured into the stainless-steel storage and feeding system (with shaftless screw conveyor), and the solid is transported from the shaftless screw conveyor to the slag discharging port on top, and discharged to the double-shaft shredder for crushing. The liquid in the swill (containing fine slurry particles) enters the water tank through the screen of the stainless-steel storage and feeding system, which is furnished with a backwashing device that can effectively prevent the screen from being clogged. The stainless-steel bin has a grille net to prevent some large pieces (plastic barrels, glass bottles, etc.) from being mixed into the shaftless screw conveyor.

The solid discharged from the shaftless screw conveyor enters the double-shaft shredder for crushing. After crushing, the swill solid is transported by the screw conveyor to the slag discharging port on top, and discharged into the pipe type magnetic separator. The magnetically selected solid enters the kitchen pulper for pulverization and pulping. The screw conveyor has its own liquid collection bin and screen backwashing device. Part of the liquid passes through the screen of the shaftless screw conveyor and enters the water tank of the feeding system.

The kitchen pulper is filled with 80°C or higher water in the pulping process to clean its screen. The light materials like plastics crushed by the kitchen pulper are discharged from the slag discharging port of the kitchen pulper and sent to the inorganic collection box through a belt conveyor; the slurry generated is discharged from the slurry port of the kitchen pulper to enter a screw extruder with a filter to form a long strip-shaped large-grain type solid to be removed. After that, the slurry is discharged from the screw extruder to the slurry tank.

The slurry produced by the liquid collection bin of the stainless-steel feeding system, the liquid collection bin of the shaftless screw conveyor, and the screw extruder enters the slurry tank. After removal of large gravel, the slurry is sent to the heating tank with steam heating and stirring functions to be heated to above 80°C. After 30 minutes of heat preservation, the slurry in the heating tank is sent to the three-phase centrifuge by a screw pump for three-phase separation of oil + water + slag.

Stainless steel storage and feeding system double-shaft shredder

Kitchen pulper Screw extruder

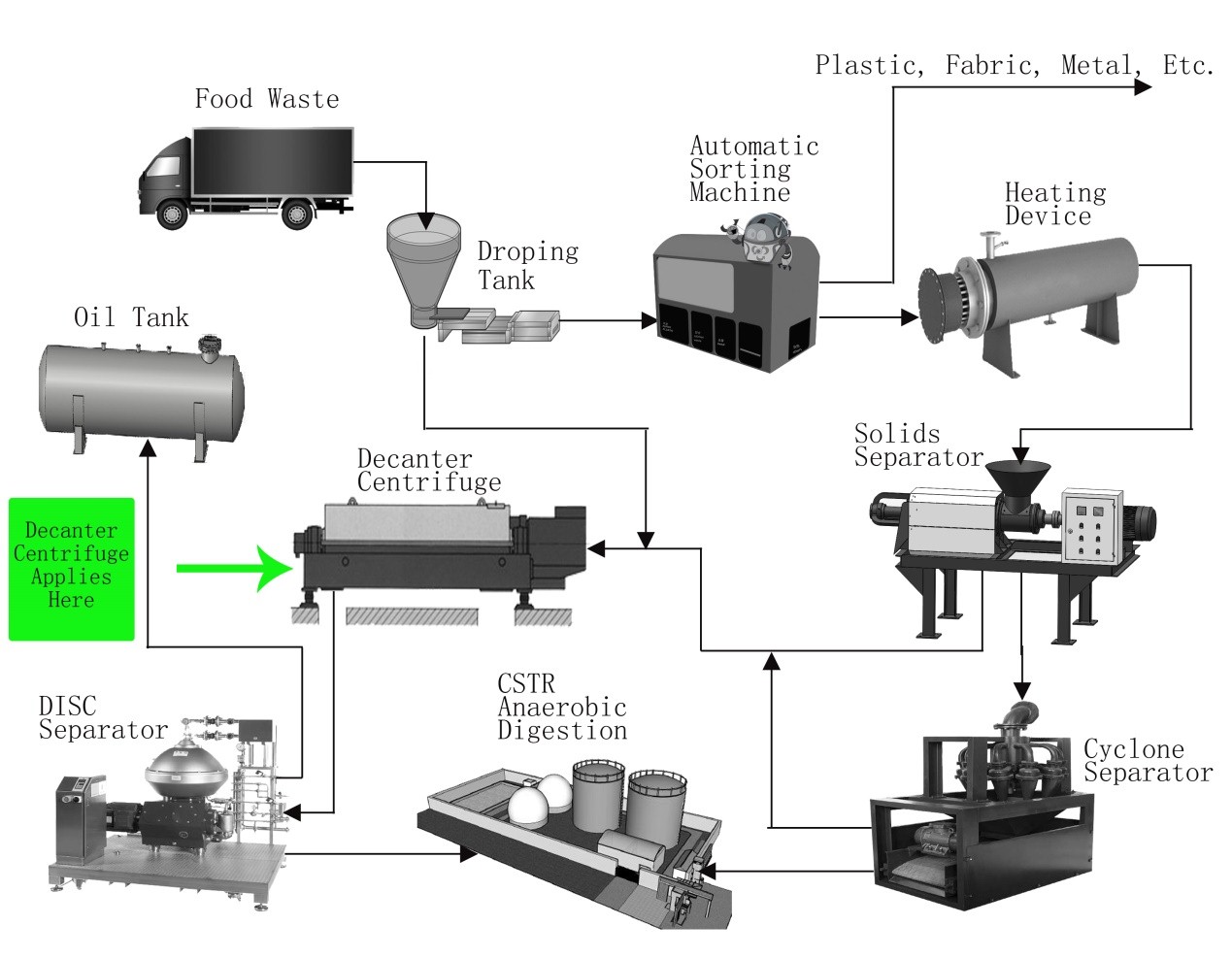

II. Kitchen wastes deoiling system

Effect of kitchen waste slurry after treatment by

The kitchen wastes after sorting, crushing, pulping, heating, and three-phase separation in the centrifuge are as follows:

S/N | Name | Parameter | Remarks |

| 01 | Solid phase (waste residue) solid content % (W/W) | ≥20-25 | Related to regional eating habits |

| 02 | Light liquid phase (crude oil) water content % (W/W) | ≤3~5 | |

| 03 | Heavy liquid (kitchen water) solid content % (W/W) | ≤1~2 | |

| 04 | Heavy liquid phase (kitchen water) oil content | No macroscopic oil | |

| 05 | Oil recovery rate % | ≥95 |

Effect after separation by the three-phase centrifuge

III. Characteristics of high-efficiency LWS series three-phase centrifuge

★ Ingenious, unique and diversified three-phase separation structure The liquid separated by the high efficiency three-phase centrifuge is discharged in two different modes, namely gravity discharging and discharging through the built-in centripetal pump with pressure, wherein the latter includes liquid layer fixed mode and the online adjustable mode of heavy phase liquid layer, which is selected according to the process conditions. |  |

★ Light phase liquid layer adjustment technology (company patent technology, patent number: 2018213324892)

The light phase liquid adjustment sheet is concealed, and the high-efficiency LWS series three-phase centrifuge adopts patented technology, so that adjustment can be completed without disassembling the machine.

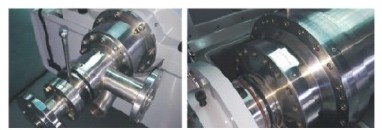

★ High performance wear-and corrosion-resistant cemented carbide

Because the kitchen waste slurry in the high temperature state contains corrosive and abrasive substances like salt, glass fragments, and sandstone, the [ZK Separation] centrifuge has a certain degree of pertinence in the selection of wear-resistant materials.

★ High performance stainless steel

After the high temperature hydrolysis of the kitchen waste slurry, due to finer solid particles and 0.1-0.08 g/cm3 liquid density difference (compared with oil and water), the centrifuge needs a separation factor of more than 3000G to achieve the best separation effect. Model SAF2205 with high strength and corrosion resistance is adopted to ensure the stability and service life of the centrifuge.

★ High-dryness screw conveyor and drum structure

The dehydration of solid particles relies mainly on strong centrifugal force, high-torque screw extrusion force (pushing torque), and ultra-long solid particle dehydration length. The [ZK Separation] centrifuge can generate centrifugal force exceeding 3000G, 30 ~ 50% higher than the screw pushing torque of common centrifuges. The screw pusher torque, and the drum dehydration length is 10 ~ 20% longer than that of common centrifuges.

★ High torque involute planetary gear differential

The ultra-high-precision torque box is based on the high-torque involute planetary gear differential. The differentials equipped for the [ZK Separation] centrifuge have high torque, high speed, low heat generation and excellent heat loss. To ensure long-term, stable operation of the centrifuge.

★ CIP washing system

The fully automatic control system is equipped with a CIP washing system, which can effectively solve the problem that it is not completely cleaned during the shutdown process and effectively avoid the equipment troubles caused by artificial factors.

IV. Kitchen wastes water treatment system

After the kitchen wastes are pretreated and deoiled, and organic matters are utilized, the remaining water must be treated harmlessly. With the rapid development of water treatment technology, whether it is the conventional water treatment process or the process of anaerobic fermentation to produce biogas, the LW series high-efficiency centrifuge (two-phase) has an indispensable role in the treatment of remaining sludge.

★ Technical features of high efficiency LW series centrifuge

• Not only equipment manufacturer but also system engineering service provider

With strong technical strength and rich engineering experience, we are fully qualified for the turnkey project of the sludge dewatering room. We are also willing to recommend the design layout of the sludge dewatering room for owners and design institutes.

• More economical in equipment investment and later-stage operation

Goal: Minimum equipment operation, maintenance and repair costs;

We are committed to creating the best quality and most cost-effective China-made centrifuge brand. We recognize that stable operation of equipment is the guarantee of greater benefits for customers, and outstanding suppliers and modern processing equipment are the basic guarantee for quality centrifuges. Advanced and unique technology is the guarantee to reduce operating cost, in addition to high-quality wear resistance, eddy current type spiral outlet, circular arc slag outlet, special spin structure, advanced electrical control technology, etc.

• Eddy current type spiral outlet

The outlet of the screw conveyor adopts a vortex type to accelerate the entry of materials into the rotating drum, thereby reducing the disturbance of the discharged materials to the formed solid phase layer and improving the processing capacity. In the industry of flocculant, it can effectively reduce the shearing effect of the discharge hole on the floccules under the high-speed discharging state, so as to reduce the consumption of chemical agent.

• BD board technology

The screw conveyor adopting BD board technology is the most advanced in the world for water content and improvement of solid recovery rate. The technology has the advantages of increasing the depth of the liquid layer, the effective settlement area, and the processing capacity of the centrifuge;

Reduce the moisture content of the sediment under the action of spiral high-pressure extrusion;

Improve solid recovery rate and make the clear liquid clearer;

Save the consumption of chemical agent and cut down equipment operating cost;

Compared with the common centrifuges of the same separation performance, it is lower in operating speed and requires less power consumption.

• High performance wear-and corrosion-resistant cemented carbide

There are inevitably small hard particles and impurities such as sand, glass, and metal in sewage. If the centrifuge does not adopt a reliable wear-resistant configuration, its service life and operational stability will be greatly affected. The wear-resistant solution is completely targeted. According to the material characteristics (pH value, corrosive substance, solid particle size hardness, etc.), cemented carbide or ceramic can be selected, and the cemented carbide can be either YG6, YG8, or various modified tungsten-cobalt alloys with the hardness of 89~93 (HRA), which can fully meet the application fields of the centrifuge.

• High performance stainless steel

Because the sewage contains some corrosive ions or substances, to ensure the stability and the service life of the centrifuge, AISI321, AISI316, AISI316L or duplex stainless steel SAF2205 with high strength and corrosion resistance are used.

• High-dryness screw conveyor and drum structure

The dehydration of solid particles relies mainly on strong

centrifugal force, high-torque screw extrusion force (pushing

torque), and ultra-long solid particle dehydration length. The

centrifuge can generate centrifugal force exceeding thousands of G,

30 ~ 50% higher than the screw pushing torque of common

centrifuges. The screw pusher torque, and the drum dehydration

length is 10 ~ 20% longer than that of common centrifuges.

• High torque involute planetary gear differential

The ultra-high pushing torque requires a high-torque involute planetary gear differential as the foundation. The differential equipped on the centrifuge features high torque, high speed, low heat generation, and excellent heat dispersion, which ensure that the centrifuge can be used for a long time and stably.

★ Humanized centrifuge configuration

1,Spiral bearing (in the drum, concealed) lubrication technology: the lubricant is filled from the outside of the hood.

2,The hood adopts a hinged opening structure and is equipped with a high-pressure gas strut to assist the opening.

Variable pitch technology is a relatively advanced technology in the world. It can effectively reduce the screw pushing torque, improve the processing capacity, and further reduce the sediment water content.

• High rigidity screw rotor technology

Decanter centrifuge is a typical high-speed rotating device with different speeds and two rotors. The rigidity of the screw rotor directly affects the stability and safety of the equipment. Through theoretical analysis and calculation, the working speed of the high-rigidity screw rotor is far from the first-order and second-order critical speeds, which can avoid the resonance state at high speed.

• Double-motor double-frequency conversion common DC bus

The main and ancillary motors of the centrifuge are controlled by a high-performance vector inverter, and the ancillary motor is always in the generator state under the action of differential speed. As The inverter adopts common DC bus technology, the auxiliary inverter can convert the electric energy generated by the ancillary motor into the power source to drive the main motor, thereby achieving the purpose of energy conservation.

Through the double-motor double-frequency conversion control technology, the stepless adjustment of the centrifuge differential speed can be realized. It features fast reaction speed, accurate torque detection, stable torque control, and low failure rate.

•• Constant torque control technology

The constant torque control of the centrifuge is the most advanced control mode in the world. The real-time monitoring of the actual output torque of the constant torque variable frequency motor through the high-performance auxiliary inverter is compared with the set torque value, and PID is used to adjust the material pushing speed of the screw conveyor in real time. The centrifuge can achieve continuous, stable, and economic operation.

★ 2phase Centrifuge model and technical paramete

| Centrifuge model | mm Drum diameter mm | Length-to-diameter ratio | rpm Speed rpm | Separation factor | rpm Differential speed rpm | kW Main motor power kW | kW Ancillary motor power (kW) | m3/h Throughput m3/h | kg Weight (kg) | mm Boundary dimension: (L x W x H) |

| LW250x1025C | 250 | 4.1 | 4500 | 2835 | 1~50 | 11 | 4 | 2~5 | 1250 | 2500×800×1150 |

| LW350x1435C | 350 | 4.1 | 3500 | 2435 | 1~35 | 15-22 | 5.5 | 5〜10 | 2500 | 3700×1050×1200 |

| LW450x1845C | 450 | 4.1 | 3200 | 2580 | 1~34 | 30-37 | 7.5-11 | 8~15 | 4200 | 4300×1150×1450 |

| LW520x2150C | 520 | 4.1 | 3000 | 2620 | 1~34 | 55-75 | 11-15 | 15-25 | 5200 | 5100×1250×1600 |

| LW580x2400C | 580 | 4.1 | 2800 | 2546 | 1~30 | 75-90 | 15-18.5 | 20-35 | 6500 | 5520×1450×1700 |

| LW650x2600C | 650 | 4 | 2600 | 2460 | 1~28 | 90-110 | 22 | 35-45 | 7800 | 6250×2000×1550 |

| LW750x2800C | 750 | 3.7 | 2200 | 2033 | 1~28 | 110-160 | 30 | 40-60 | 11000 | 6500×2200×1600 |

The length dimension varies with motor power.