Ningbo Jiajie Electronics Co.,Ltd. |

|

Jiajie JT3 10A 125V Three Prong Power Cord for Laptop UL cUL

Approval American Canadian Cable

PRODUCT DESCRIPTION

Typical laptop type cable universally fits for American appliances. This three prong power cord plug’s rated current is 10A and rated voltage is 125V. The available wire gauge types are 14AWG, 16AWG and 18AWG. Sheath material can be PVC or rubber. And the blade material is nickel coated brass.

Before packing, we will have the tests of hi-pot, polarity and continuity. The color of power cord can be black, white, gray or customized, as well as the length. Our products have passed UL cUL certificates. And they are also environmentally friendly as we passed RoHS.

PRODUCT SPECIFICATION

| Items | Details |

| Plug Type | JT3 |

| Maximum Current rating | 10A |

| Maximum Voltage | 125V |

| Wire Gauge | 14/ 16/ 18 AWG |

| Jacket Type | 18 SJT, SJTW, SJTO, SJTOW, SJTOO, SJTOOW, SVT, SVTO, SVTOO, ST,

STW, STO, STOW, STOO, STOOW 16 SJT, SJTW, SJTO, SJTOW, SJTOO, SJTOOW, ST, STW, STO, STOW, STOO, STOOW 14 SJT, SJTW, SJTO, SJTOW, SJTOO, SJTOOW |

| Length | 3 , 6 , 10 Foot ( Custom Lengths Available - 24 hr. Turnaround ) |

| Color | Black is standard but any color available |

| Approvals | cUL, UL certification |

| Application | Used for laptop,camera or other home appliances |

| Blade Material | Nickel coated Brass |

| OEM | Yes |

| Environmental Certifications | ROHS |

| Testing | Hi-Pot (Dielectric Withstanding Voltage), Polarity (pinout) and Continuity |

| Package | Inner packing:PE bag or as per request |

| Outer packing:Carton packaging | |

| Shipping way | By express,By sea,By air |

| Payment terms | T/T or L/C |

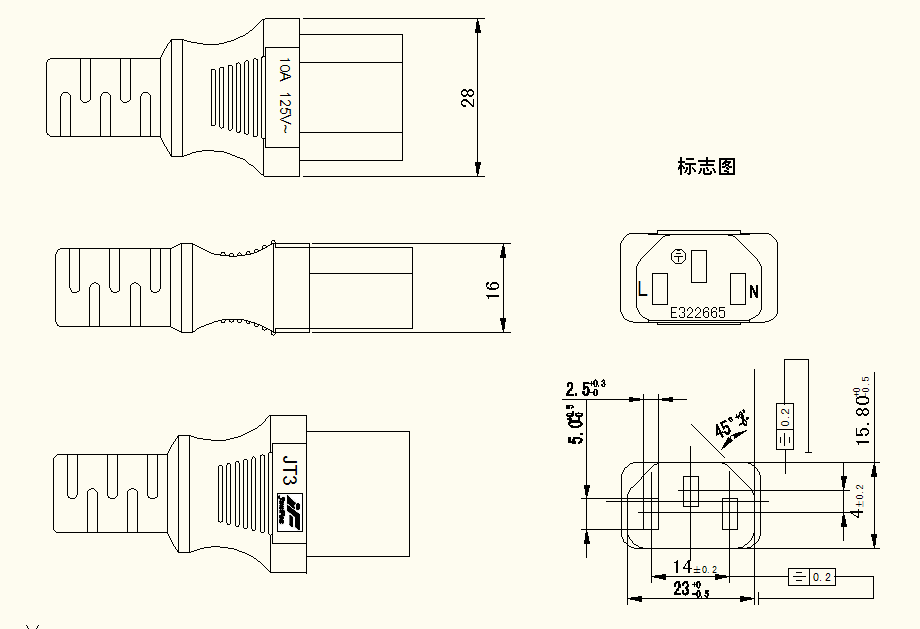

TECHNICAL DRAWING

AVAILABLE WIRE TYPES

| Wire Gauge | Wire Types |

| 18AWG | SJT, SJTW, SJTO, SJTOW, SJTOO, SJTOOW, SVT, SVTO, SVTOO, ST, STW, STO, STOW, STOO, STOOW |

| 16AWG | SJT, SJTW, SJTO, SJTOW, SJTOO, SJTOOW, ST, STW, STO, STOW, STOO, STOOW |

| 14AWG | SJT, SJTW, SJTO, SJTOW, SJTOO, SJTOOW |

PACKAGING INFORMATION

Internal Packaging:

1. 5/10 pieces each bundle (or according to length)

2. PP bags and vacuum package as per request

External Packaging:

1. Usually, we use high quality export carton to package the power cord.

2. Carton size: 52*30*22CM/ 43*30*28CM/ 43*30*24CM or customized

3. Packing (pcs/carton): It depends on the types of power cords and the length of power cords.

4. Or according to per customers' requirement, we can customize a new size carton in order to help customers save shipping fee.

P.S. Other special requirements are also available.

MANUFACTURING PROCESS

The production of power cord is a huge data, so its manufacturing technique must be very stable and reliable. The specific steps are as follows:

1. Wire Drawing

Power cords often use copper or aluminum material for its inner core. At normal temperature, rod shaped copper or aluminum passes through one or several die holes of drawing machine.

2. Wire Annealing

Copper and aluminum wire should be heated up to a certain temperature. The key of annealing process is to avoid the oxidization of copper.

3. Wire Stranding

In order to further increase the flexibility of the power cord, the conductive wire needs to be stranded by several single wires. the stranding process will use the pressure method to make the regular round shape into half round, fan-shaped, tile-shaped and tightly pressed round.

4. Power Cord Insulation Extrusion

The plastic power cord mainly use the solid insulation layer. And the main technical requirements of the extrusion of insulation are:

4.1 Lubrication Degree: the appearance of extruded insulating layer need to be smooth, can not be rough, burned or impure.

4.2 Density Degree: the cross section of the extruded insulation should be tight. There can not be visible pinholes or bubbles.

5. Power Cord Cabling

The stranding way of these wires is the same as the conductor’s. Cabling technology requires: first, avoid twisting of power cord caused by core wire’s turning over; second, avoid scratching on the insulating layer.

Part of the power cord has another two steps: one is padding which makes power cord rounding; the other is strapping, so that core wires are not loose.

6. Power Cord Sheathing

The main effect of the outer sheath is to increase the mechanical strength of the power cord, to prevent chemical erosion, moisture, water, and prevent the power cord from burning, etc.. According to the different requirements of the power line, this process should directly use extrusion machine to make the plastic sheath.

PICTURE