Jiangsu Shengman Drying Equipment Engineering Co., Ltd |

|

Verified Suppliers

|

|

DWT-1.2-10 Garlic Onion tomato dehydrator Drying Machine/Nuts Dryer Conveyor Belt Dryer

Description

This machine is a continuous penetrating flow drying equipment applied for drying pieces strip and particles state materials with good ventilation. The machine is suitable for the materials such as de-watering vegetable, fruit, herbal medicine of traditional Chinese medicine and others, for which the water contents are high and high drying temperature is not high. The machine owns the advantages, of fast drying speed, high evaporation capacity and good product quality. The de-watered & filtered cake state paste material should be made into particles or strips before drying process.

Working

The materials are evenly displayed on the mesh-belt by the material feeder. The mesh-belt uses generally 12-60 mesh stainless wire net and it is drawn and moved inside the drier by a transmitting device. The drier is composed of several units. For each unit, the hot air is circulated separately. Some exhausted gas is discharged with a special moisture elimination blower. The waste gas is controlled through an adjusting value. The hot air passes through the mesh-belt covered with the material from the top to the bottom or from the bottom to the top and this will complete the transmitting of heat and mass. This process will bring water away from the material. The mesh-belt moving slowly, running speed can be easily adjusted. According to the material temperature. The final products after the drying will fall into the material collector continuously. The upper and lower circulating units can be freely equipped according to the users’ requirements.

Technical parameters

| spec | unit | DWT-1.6-1 | DWT-1.6-2 | DWT-1.6-3 | DWT-2-1 | DWT-2-2 | DWT-2-3 |

| fed table | middle table | discharge table | Fed table | middle table | discharge table | ||

| belt width | m | 1.6 | 1.6 | 1.6 | 2 | 2 | 2 |

| drying length | m | 10 | 10 | 8 | 10 | 10 | 8 |

| thickness of material | mm | ≤100 | |||||

| temperature | ℃ | 50-150 | |||||

| steam pressure | Mpa | 0.2-0.8 | |||||

| drying time | h | 0.2-1.2 | |||||

| power | kw | 15.75 | 512.75 | 9.55 | 20.75 | 16.75 | 12.55 |

Remark:

1. Parameters above in the table are regular model for reference;

2. We could make special model / size according to the customer's actual situation or requirement, please contact sales team to konw more details about vegetable dryer.

Application

De-watering vegetables, particle feed, gourmet powder, fine coconut mash, organic plastics, compound rubber, acrylic acid fiber, medicine product, medicine material, small wooden product, plastic product, aging and solidification for the electronic components and devices.

Features

1. In the mesh belt dryer system, the following data can be a special set and adjusted in order to achieve the best drying effect: heating temperature, air flow, staying time.

2. Agility specified: we can add mesh belt washing system and product cooling system in mesh belt dryer system.

3. Agility operating: after conveying on mesh belt, wet material is dried in a totally sealed chamber during the whole drying process. Working condition is good because the system does not have powder leaking outside.

4. When wet material loaded in conveying belt, the relative position between every single material is quite stable. So for every single material, drying time is almost the same. This is especially suitable for drying that product that needs good color and uninformed water content. Additionally, during a drying process, the product will not be heavily shocked and vibrated, so granule size of granule will not break down. So this kind of mesh belt dryer is especially suitable for that product that should keep the good shape.

5. Our mesh belt dryer can also bake, cook and cooling raw material besides other than drying function.

6. Our mesh belt dryer designed intelligent air distribute construction in order to separate hot air into every single material uninformed.

7. Total construction is not complicated by Rank design. Through our human design principle, mesh belt dryer is easy for assembly, each for maintenance and transportation.

Company Introduction

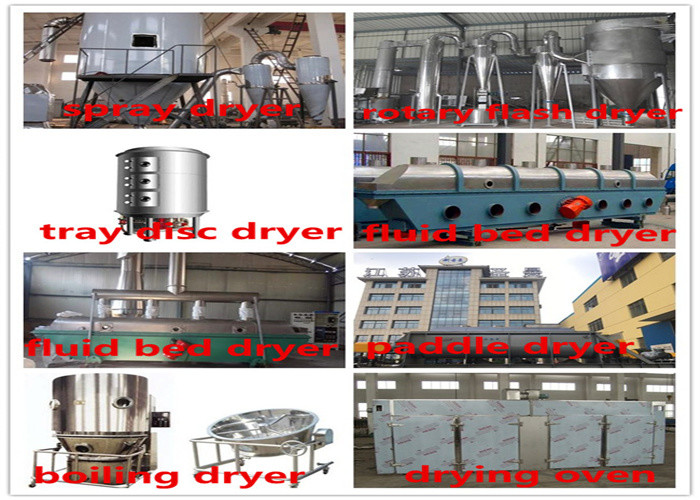

Jiangsu Shengman Drying Equipment Engineering Co.,Ltd, established in 2011, known as a local leading high-tech enterprise, is located in Zhenglu town, Changzhou, Jiangsu, China. Shengman is a large-scale production enterprise in China drying industry with a registered capital of 35,000,000 RMB, specialized in designing &manufacturing various kinds of dryers, granulators, mixers, grinders ,dust removers, etc. Shengman owns an area of over 200,000㎡, and realizes annual sales of over 70,000,000RMB for consecutive years. Shengman has passed European Union CE authentication, ISO 9001 quality management system certification and got good bank credit for AAA. Now Shengman has been one of the largest drying equipment production enterprises in East China and keeping leading the drying industry’s development.