HK Risingsun Trade Co.,Limited |

|

Item No.: RS-TM-600-OD2

Rubber High Mold Temperature Controller/ Direct Cooling Oil Mold Temperature regulator

Description of the Oil Type Mold Temperature Controller,

The TM-O series of oil heaters are used to heat up the mould and maintain this temperature, although they can be used in other similar applications. High temperature oil from the mould is returned to the cooling tank and cooled by indirect cooling. It is then pressurised by the high-pressure pump, sent to the heating tank and finally to the mould with a constant temperature and accurate PID multi-stage temperature control system.

Features of the Oil Type Mold Temperature Controller,

PID multi-stage temperature control system can maintain a mould temperature with accuary of ± 1℃

Multiple safety devices can automatically detect abnormal performance and indicate this via visible alarm.

Reliable mains isolator to cut power supply in case of emergency.

High temperature heat transfer oil is stable up to 200℃,suitable for long and continuous operation.

Attractive appearance,easy to access and maintain.

Specification of the Dual Stage industrial oil mould temperature controllers,

Model | Max Temperature | Pump

Heatei <kW) | Pump Power <kV/) | Max pump Flow (L/rnin) | MaxPump Pressure

(bar) | Heating Tank Number | Main/sub oil tank (L) | Cooling Method | Mould Coupling (Inch) | Demensions (HxWxD) (mm) | N.W. Kg |

TM-600-D | 200°C | 6x2 | 0.55x2 | 27x2 | 3.8 | 2 | 6x2/3.2x2 | Direct | 3/8"(4x2) | 655x560x740 | 130 |

TM-900-D | 9x2 | 0.75x2 | 42x2 | 5.0 | 2 | 6x2/3.2x2 | 3/8"(4x2) | 655x560x740 | 140 |

Note,

1) “ D” stands for dual-heating zones, “ HT ” stands for high temperature;

2) Pump testing standard:Power of 50Hz,purified water at 20

3),Power Supply:3⊙ ,400V,50Hz

Application of the industrial oil mould temperature controllers,

The Mold Temperature Controller is suitable for Reaction kettles, extrusion forming equipment, rubber forming machinery, cast film production lines, cable extrusion production lines, the dies for precise plastic molding, the dies for the compression casting of magnesium/aluminum/zinc alloy, roller pressing applied in rubber/plastic and leather industries, crude oil heating of the oil sinks on tank ships, paper making industry, bottle blowing, and so on.

The Mold Temperature Control System has been designed to maintain a constant temperature, using water or oil as medium. Mold temperature controller is used to control temperature in various industrial fields.

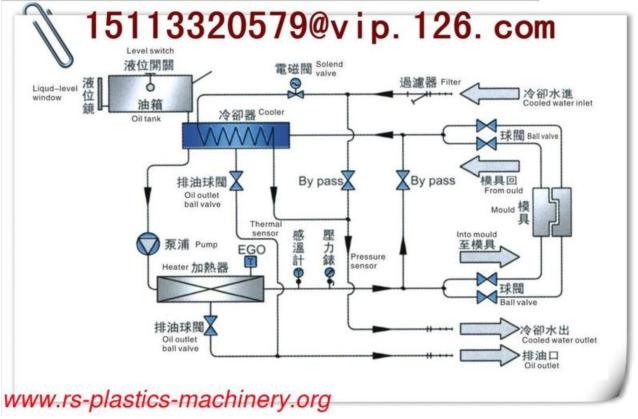

Working Principle of the industrial oil mould temperature controllers,

High temperature oil returns to the machine and then be pressured by pump to the heaters, After being heated, oil will be forced to mould and continue the circle. In the process, if the temperature is too high, the system will activate the solenoid valve to let return oil cool down the temp, directly till the oil temp, is down to the system requirement. If the temp, keep rising and reach to the set point of EGO, the system will alarm and stop working if cooling water pressure doesn't reach set point.

Model Selection Guide for Oil Mold Temperature Controller,

Mould Clamping Force (T) | Moulding Capacity Kg/hr | Pump Flow L/min |

| |

25U Below 25T | 3T Below 3T | 10 |

| |

25-50 | 3-6 | 25 |

| |

200-300 | 25-40 | 40 | ||

300-650 | 40-80 | 60 | ||

650 above | 80 above | 120 | ||

Machine color--- blue or white, or others;

Machine brand--- factory brand, OEM brand or no brand;

We do OEM!

We do B2B, B2C!

We do Paypal,West Union, T/T and L/C!

RS Plastics Machinery Co.,LTD (Zhongshan·China) | |||

Contact Person | Mrs. Pearl Zhu | Position | Export Manager |

Mobile Phone | 0086-13590932590 | 263567704 | |

Wechat APP | zhhy18 | Skype | PEARL20128 |

E-mail-1 | |||

E-mail-2 | |||

Website | |||

For more details of the China Dual Stage Oil Mold Temperature Controller, please contact us for E-sheets!

For more choice of China Mold Temperature Controllers, China plastic industry machinery manufacturers products, please contact us for E-catalogue and Price Lists!

If there are any questions on China plastic industry machines, please feel free to contact us.

We can provide all kinds of China plastics machinery manufacturer solutions to meet your special demands accordingly at one-stop purchasing!