Wuxi YBT Machinery Equipment Co.,Ltd. |

|

12-15m / min Door Frame Roll Forming Machine Easy to Operate Thickness 0.8-1.5mm

Production Description

Door Frame Roll Forming Machine is cold-rolled into various wave-shaped pressed plates. It is suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decoration of large-span steel structures. It has the characteristics of light weight, high strength, rich color, convenient and quick construction, anti-seismic, fireproof, rainproof, long life and maintenance-free. It has been widely used.

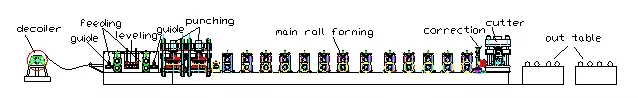

Production process

Decolier----> Punching----> Feeding guide----> Roll forming machine----> hydraulic following cutting----> Finished products on run out worktable

No. | Item | Description |

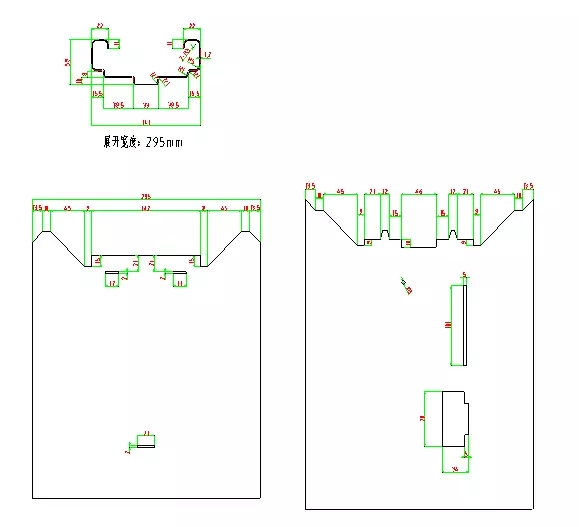

1 | Coil width | 295mm |

2 | Rolling speed | 12-15m/min(not include cutting & punching time) |

3 | Rolling thickness | 0.8-1.5mm GI, G550 |

4 | Control system | PLC (Panasonic) as list in the note |

5 | Un Coiler | 5T hydraulic decoiler |

6 | Leveling | Three rollers four |

7 | Punching | 4 sets |

8 | Shaft Material and DIA | ¢65mm, material is 45# forge steel |

9 | Roller stations | About 19 stations (according the final design) |

10 | Roller material | Gcr15, HRC55-60 surface coated with chrome |

11 | Post cutting | Hydraulic cutting after roll forming |

12 | Material Of Cutting | Cr12Mov quenching 58-62℃ |

13 | Maim Motor Power | 11kw |

14 | Hydraulic Station Power | 5.5kw |

15 | Hydraulic Pressure | 12-16Mpa adjustable |

16 | Sturcture Of The Stations | Wire-electrode cutting |

17 | Electric Source | 380V, 50HZ,3 phase According to customer's require |

18 | Way Of Drive | By chain |

Components and Technical Specification

1. Manual Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Inner diameter: 500-508mm

2. Feeding Table

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

3. Hydraulic System

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

4. Computer Control Cabinet

The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

5. Cutting System:

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

6. Output Table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Machine Details