Wuxi YBT Machinery Equipment Co.,Ltd. |

|

Automatic Guide Roller Shutter Door Making Roll Forming Machine

The shutter door roll forming machine can make metal steel shutter doors,the shutter door can be used for shop, workshop, garage.Normally, the raw material of shutter door is the galvanized steel,the regular thickness is from 0.8mm to 1.2mm.

Details of Shutter Door Roll Forming Machine

Working Material :Galvanized Sheet(Gi),Cold Roll Steel(CRC),Hot Roll

Thickness:0.8-1.2mm

Decoiler:Manual/Hydraulic for Options

Housing:H200 Beam

Cutter Material:Cr12 Tool Steel

Transport Package:Naked and Covered by Plastic Film Into Container

Output:About 15 Meters Per Minute

Forming Station:14

Side Wall Thickness:18mm

Details of Roller Shutter Door Roll Forming Machine

| Material Thickness(&):0.6--1.2mm |

| Raw material:Galvanized Steel Coils, Cold Rolled Coils,yield strength 245Mpa or 550Mpa |

| Transport Package:Naked and Covered by Plastic Film Into Container |

| Delivery time :45-60 working days |

| Forming speed approx.15-18m/min |

Machine Components

A. Manual Decoiler: one set

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max. 3Ton

B. Cold Rolling Mills

Rollers manufactured from bearing steel GCr15,precision machined,Motor Driving,Gear chain transmission,

Main Motor=5.5KW , Frequency speed control

C.Hydraulic Cutting device

hydraulic motor: 2.2KW, Hydraulic pressure range: 0-16Mpa

Cutting tool material: Cr12, Heat treatment

D. PLC Control System :Brand Siemens,Schneider,Mitsubishi Electric

Services

1 .We can send our technicians to install and train the workers in the clients' factories with extra cost.

2 .The warranty of YBT Shutter Roll Forming Machine is one year after the client receives the machine.Within the one year, we will offer the replacement parts to the client free of charge.

3 . We offer technical support for the entire life of our machines.

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

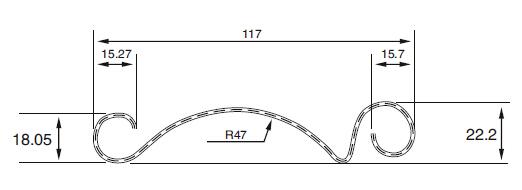

Show us your drawing of shutter door

After-sale service:

We supply one year guarantee for the machine. The parts of the roll forming machine are free to send you and

you will pay the cost of freight. And you can aslo solve it if you ordered more parts for your rol forming machine

We supply all life tech support of our roll forming machines, Any questions, you can contact me by whatsapp.

( I suggest that whatsapp or wechat is good. Because i can get your words timely) Important thing, or you can write mail to me.

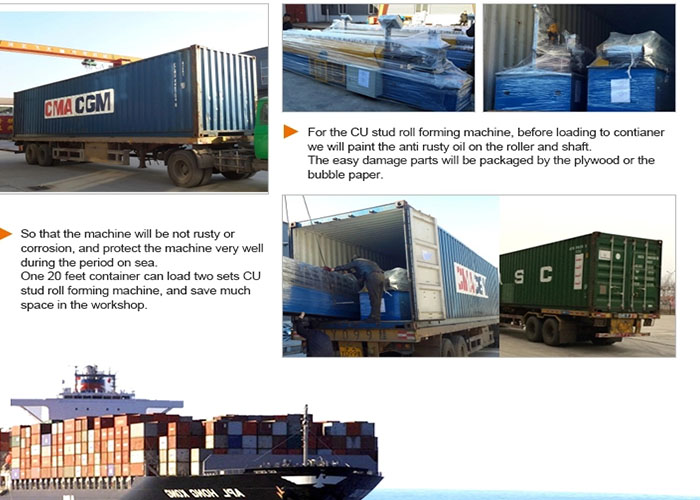

Package

(1) Main body of Shutter Door Roll Forming Machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into container and steadily fixed in 1x40GP container with steel rope and lock catch suitable for long-distance transportation,

(2) spare parts are covered by plastic film.

(3) With even lifting point in the machine for easy container loading and uploading.