Wuxi YBT Machinery Equipment Co.,Ltd. |

|

Flying Saw Cutter Downpipe Roll Forming Machine for Rainwater Downpipe with PLC

Introduction

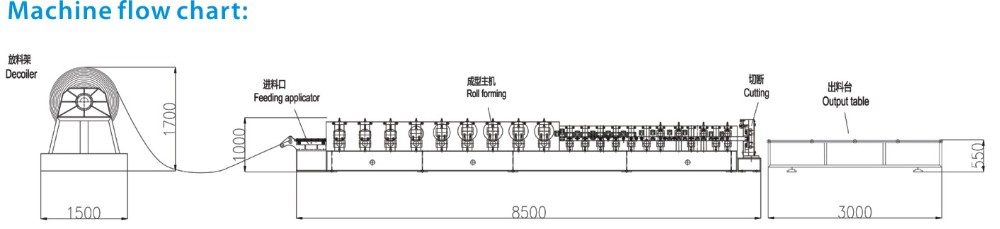

Downpipe roll forming machine consists of uncoiler, infeed guides, fixed position driven forming stations, shearing device, hydraulic station, PLC control console and so on. We can design different kinds of profile for downpipe machine, as per customers’ requirements. Closed type color coated steel downpipe is cold rolled and automatically edge interlocked by downpipe roll forming machine, the finished products are of many features, such as good interlocking, no leak, beautiful integrity, long time using and so on. This series machine is matched with downpipe bending (elbow) machine, used for bending and end narrowing. The angle of bending can be adjusted by manual according to engineering requirements. Colour coated steel downpipe is widely used in workshops, warehouse, hangar, gym, and so on for industry &civil buildings.

Profile drawing:

Main Specifications

Specification of Components

| No | Technical Specification & Remark | |

| 1 | Hydraulic Uncoiler |

|

| 2 | Main Roll Forming Machine |

|

| 3 | Machine structure: |

|

| 4 | Hydraulic cutting system |

|

| 5 | Hydraulic System |

|

| 6 | Computer Control Cabinet |

|

| 7 | Out table |

|

| 8 | Bending machine |

|

Guarantee:

1: Guaranteed against malfunctions due to manufacturing defects for 1 year after date of shipment. Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3: Air ticket, transportation cost, hotel, meals and 100$ per day shall be for purchaser’s account if manufacturer’s engineer has to be send to purchaser’s factory to maintain the machine during the guarantee period.