Changzhou Daye Energy Technology Co., Ltd. |

|

Hydrogen generator HHO hydrogen water generator Engine Carbon Cleaning Machine for the car

Comparing with other suppliers, we have below advantages:

For example, high precision vibration sensor with flameout protection.If engine accidentally stops during the decarbonizing procedure, the hho gas will stop immediately to prevent too muchgas into cylinder to cause explode.

Comparison between Daye energy carbon cleaning system and traditional methods

| Item |

Daye Energy

| Chemical Drip Method | Chemical Foam Method |

| Medium |

Oxy-hydrogen gas

| Chemical additive | Chemical additive |

| Procedure time |

15mins

| 30-40mins | 30-40mins |

| Environment Issues |

None

| Air pollution +waste water | Waster water |

| Advantages / Disadvantages | Simple to connect the engine runs at idle | The engine runs at idle while chemical additive drips into the engine | Complicated and repetitive; Carbon removal incomplete; |

| Cost ( Retail ) | Carbon Cleaning Process | Chemical Drip Engine oil Engine oil filter | Chemical Foam Engine oil Engine oil filter |

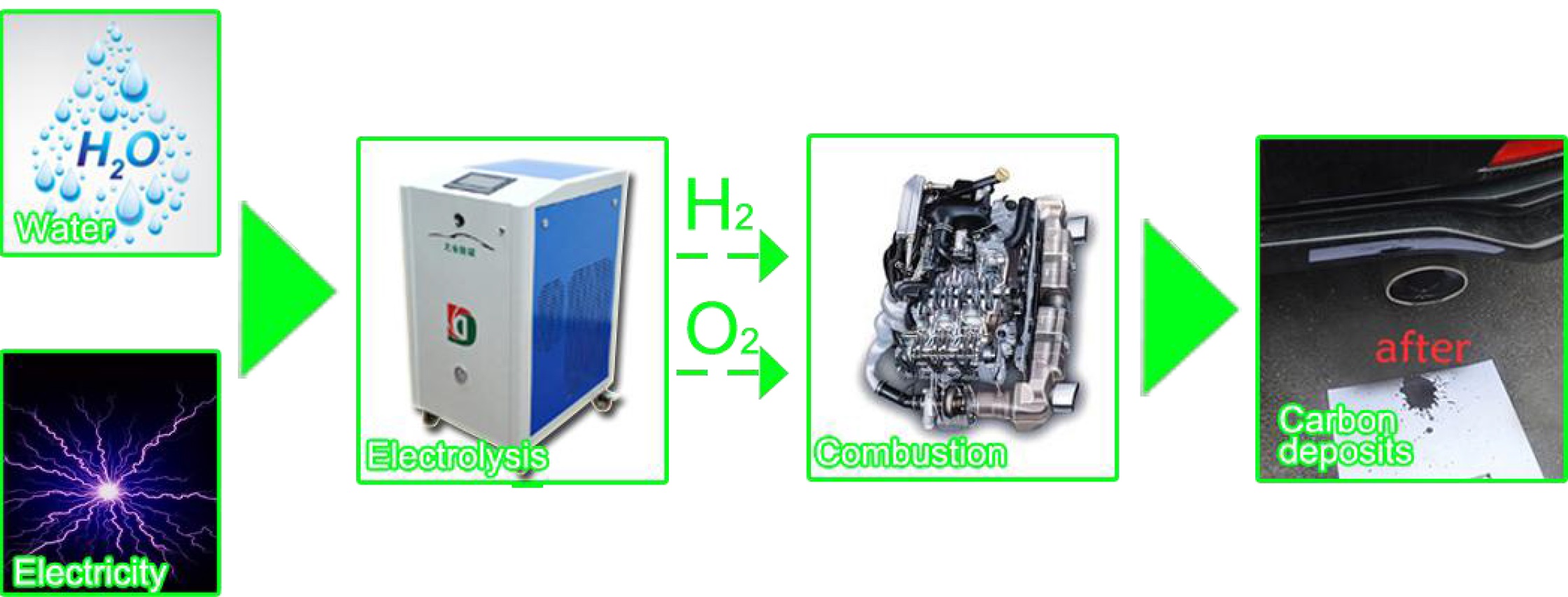

HHO Carbon Cleaning Machine Principle

Daye Energy carbon cleaning machine produce oxy-hydrogen gas from water ,the gas enter into the car engine,

after burning it into high temperature water vapor to soften and clean the carbon deposit.

How to operate?

Our Support

Daye has passed ISO9001:2000 international quality management system, and the machine passed CE certification.

We guarantee 30 days refund, 1 year replacement, lifetime warranty ater-sales service.

For personal

For distributors

Comparison between Daye energy carbon cleaning system and traditional methods

| Item |

Daye Energy

| Chemical Drip Method | Chemical Foam Method |

| Medium |

Oxy-hydrogen gas

| Chemical additive | Chemical additive |

| Procedure time |

15mins

| 30-40mins | 30-40mins |

| Environment Issues |

None

| Air pollution +waste water | Waster water |

| Advantages / Disadvantages | Simple to connect the engine runs at idle | The engine runs at idle while chemical additive drips into the engine | Complicated and repetitive; Carbon removal incomplete; |

| Cost ( Retail ) | Carbon Cleaning Process | Chemical Drip Engine oil Engine oil filter | Chemical Foam Engine oil Engine oil filter |