Anping County Hengyou Wire mesh Products Co., Ltd |

|

self furring metal mesh/expanded metal wire/how to install metal lath for sale/roll lath/ how to install stucco lath

High Ribbed Form work is manufactured from hot-dipped galvanized steel sheets. Because its meshes and U patterns, it has better anti-stress capability and forming flexibility than normal metal lath. This product has excellent engineering quality, construction security and widely used in tunnels bridges, valve basement systems, sewage systems, subways, retaining walls, nuclear power plants, shipyards, water pools and marine engineering works and high rise building projects and non-regular or bending pattern etc.

Specification of Expaned galvanized plaster rib lath:

| Thickness(mm) | mesh(mm) | Rib height(mm) | Rib distance(mm) | kg/m² | Width of panel(mm) |

| 0.30 | 16X11 | 8 | 150 | 0.85 | 600 |

| 0.35 | 16X11 | 8 | 150 | 1.00 | 600 |

| 0.40 | 16X11 | 8 | 150 | 1.14 | 600 |

| Thickness of panel(mm) |

mesh(mm) | Rib height(mm) | Rib distance(mm) |

kg/m² | Width of panel(mm) |

| 0.30 | 7X11 | 8 | 100 | 1.165 | 600 |

| 0.35 | 7X11 | 8 | 100 | 1.36 | 600 |

| 0.4 | 7X11 | 8 | 100 | 1.55 | 600 |

High Rib Lath

| Rib Height | Width | Length | Thickness | Materials |

| 3mm | 610 | 2000mm-2500mm | 0.25mm-0.50mm | Galv. |

| 4mm | 600mm | 2000mm-2500mm | 0.30mm-0.50mm | Galv. |

| 10mm | 600mm | 2000mm-2500mm | 0.30mm-0.50mm | Galv. |

| 3/8'' | 27'' | 97'' | 3.4lbs/sq yard | Galv. |

| 3/4'' | 27.5'' | 97'' | 5.4kg/sheet | Galv. |

| 25mm | 700mm | 2000mm-2500mm | 0.50mm | Galv. |

Specification:

| Product | Thickness (mm) | Weight (kg) | Width (mm) | Length (mm) | Rib Height (mm) | Rib Distance(mm) |

| High Ribbed Formwork | 0.21 | 1.70 | 450 | 2200 | 14-20 | 90 |

| 0.23 | 1.90 | 450 | 2200 | 14-20 | 90 | |

| 0.30 | 2.48 | 450 | 2200 | 14-20 | 90 | |

| 035 | 2.90 | 450 | 2200 | 14-20 | 90 | |

| 0.40 | 3.30 | 450 | 2200 | 14-20 | 90 | |

| 0.45 | 3.70 | 450 | 2200 | 14-20 | 90 | |

| 0.50 | 4.10 | 450 | 2200 | 14-20 | 90 |

The Usage of Rib Lath

1.Used as fire wall in high and low residential building;

2.Used to construct partition;

3.Used as floor slab or partition wall;

4.Used as inside and outside wall and enclosure of the permanent

house;

5.Used in protection against the tide;

6.Used in tunnel, sewer and fence;

7.Used in shipyard and retaining wall;

8.Used as panel and arch floor;

9.Used in nuclear power plant, storage bunker, etc;

10.Used in special projects, such as, landscaping, sculpture, etc;

11.Used in slope protection, claybank,etc.

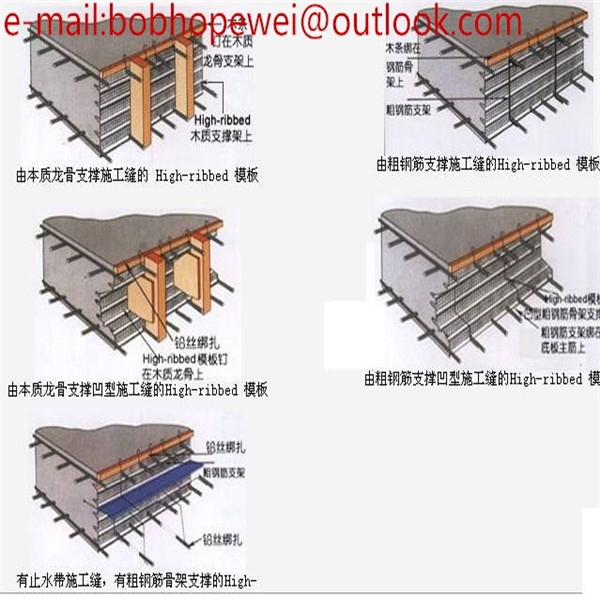

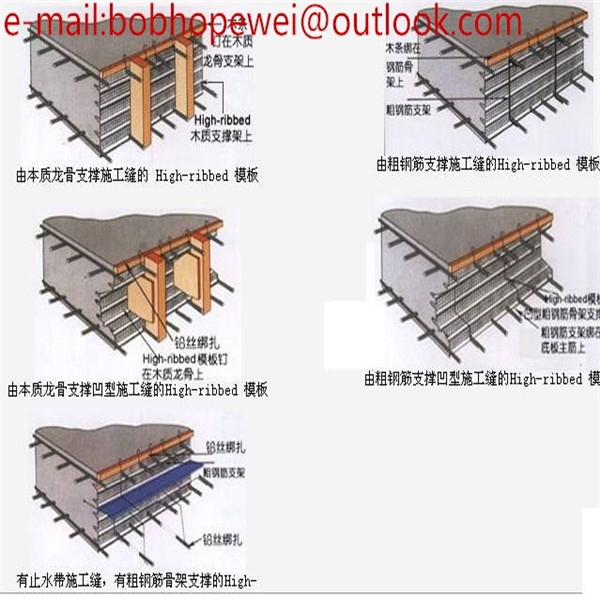

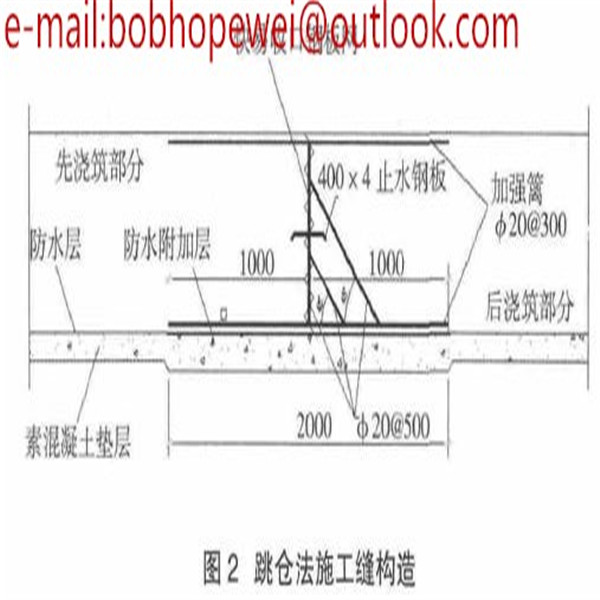

Installation:

Hi-rib lath is ideal for refurbishing damaged or aged masonry

walls, when a key for rendering is not certain due to

disintegration or softening of the wall face.

Lath should be fixed with apexes of ribs against the wall, edge

ribs of sheets nesting into each other should be wire-tied every

15cm and ends of sheets should be lapped not less than 2.5cm and

nesting ribs securely tied together.

Stainless steel fixings should be used at sufficient intervals to

hold the lath firmly in position.

Packing & Shipping

seaworthy packing 2. according to customer's requirement

Water-proofed parper ,plastic film

1. Is your samples free?

Yes, we can provide free samples to my clients.

2. How many days will the samples be finished?

Generally the samples will be sent immediately by the air express

in 2~3 days if the goods are in stock.

3. And how about the mass production?

Normally within 20-25 days according to your order.

4. Are you a manufacture?

Yes, we have been in providing the products in this field for 15

years.

5. Is customized availabls?

Yes, we can OEM according to your detailed drawings.