JIANGSU HUI XUAN NEW ENERGY EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

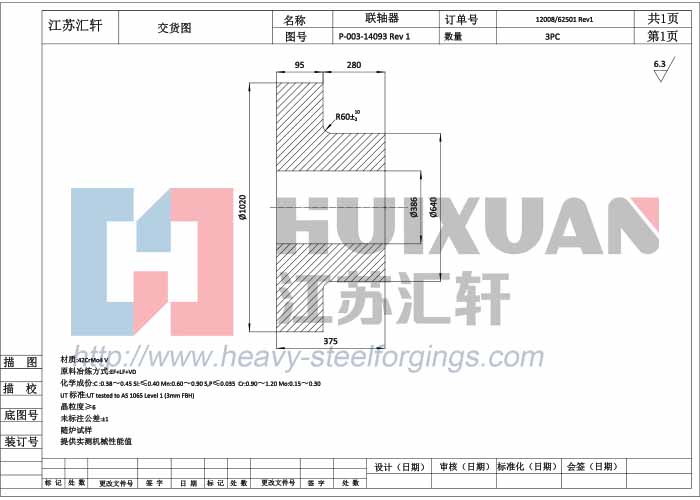

18CrNiMo7-6 LF EF VD Flanges Rough Machined Coupling Forged Steel

A.Content of Delivery

| Item No | Quantity(Pcs) | Description | Heat No | Factory Product No |

| 00116045 | 10 | Φ663*185 | 20170414-206 | 5793-5802 |

B.Chemical Analysis

| Heat No | C% | Si% | Mn% | S% | Cr % | Mo % | P% | Ni% | H% |

| 18CrNiMo7-6 | 0.15-0.21 | 0.17-0.35 | 0.50-0.90 | 0.008-0.016 | 1.50-1.80 | 0.25-0.35 | P≤0.015 | 1.40-1.70 | H≤2.0 |

| SX1702049 | 0.18 | 0.29 | 0.72 | 0.008 | 1.64 | 0.28 | 0.010 | 1.45 | 1.6 |

C.Mechanical Properties Tests

| Specimen | Test Temp | Yield Strength | Tensile Strength | Elongation(Tr) | Reduction of Area | Charpy Impact(20℃) | Hardness | |

| Nr./No | 20℃ | Rp0.2 N/mm² | Rm N/mm² | A% | Ψ% | Joule | HB | |

| 18CrNiMo7-6 | L | T | 179-229 | |||||

00116045 Sample position 1(T) | 205-217; 207-246(YL5800) | |||||||

FORGING REDUCTION STATEMEN

We hereby certificate that the forge reduction ratio as follow:

| Item No | Dimension | Forging Reduction | Quantity(Pcs) |

| 00116045 | Φ663*185 | 4:1 | 10 |

Metallographic Test Report

| Sample Name | Forged coupling | Item No: | 00116045 | Factory Product No | YL5793-YL5802 | |||||

| -YLQuantity( Pcs) | 10 | Material | 18CrNiMo7-6 | Heat No | 20170414-206 | |||||

| Sample Condition | OK | Heat treatment | Q+T | Test Place | Laboratory | |||||

| Ambient Condition | 23℃ | Test Date | Sampling Location | Longitudinal | ||||||

| Test Standard | ASTM E45-76 Method A | |||||||||

| Test Results | ||||||||||

| Test Item | Technical Requirements | Test Results | Single Evaluation | |||||||

Non-Metallic Inclusions | Type A | Thin | ≤1.5 | 1.0 | Qualified | |||||

| Thick | ≤1.5 | 0.5 | Qualified | |||||||

| Type B | Thin | ≤1.5 | 1.0 | Qualified | ||||||

| Thick | ≤1.5 | 0.5 | Qualified | |||||||

| Type C | Thin | ≤1.0 | 0.5 | Qualified | ||||||

| Thick | ≤1.0 | 0 | Qualified | |||||||

| Type D | Thin | ≤1.5 | 1.0 | Qualified | ||||||

| Thick | ≤1.5 | 0.5 | Qualified | |||||||

| Grain size | ≥6 | 7 | Qualified | |||||||

| Statement:This report only responsible for samples | ||||||||||

Certificate of Ultrasonic Test

| Parts | Customer | Date | 2017-04-27 | ||||

| Name of forging | Forged coupling | Testing surface | Surface | ||||

| Material of forging | 18CrNiMo7-6 | Surface condition | Ra 6.3 μm | ||||

| Test Condition Requirement | Woke piece state | Q+T | Detection method | Straight vertical Wave | |||

| Instrument model | HNW-6100 | Working sensitivity | Φ4 | ||||

| Prode model | 2.5P20 | Coupling way | Direct contact | ||||

| Block model |   Big calm bottom CS-1 Big calm bottom CS-1 | Couplant | Machine oil | ||||

| Sweep | Deepness way | Surface compensation | 0db | ||||

| Standards | AS 1065 | Rate as require | 1:1 | ||||

| Acceptance standard | Level 1 | Acceptable class | ≤Φ4 | ||||

| Test Result | Item No | Forging specifications | Qty | Defect | Result | Note | |

| 00116045 | Φ663*185 | 10 | None | Qualified | / | ||

| Test Result | 1.The above forgings are meet the standard,The result is eligibility | ||||||

| Nondestructive testing Signature | Tested by:(UT-II) | Approved by:(UT-III) | |||||