Guangyuan Technology (HK) Electronics Co., Ltd. |

|

Verified Suppliers

|

|

Fast Heating Industrial Induction Heating Machine 380V 3phase For Steel Plate Heating

GY Induction heating machine adopts the most advanced technology MOS-FET, IGBT frequency conversion control to ensure high efficiency and maximum out-put power.

Call us for money-saving,apply for heating,brazing,annealing,hardening,melting and so on.Benefit from our induction heating consultants nearly 27 years experiences creating precision heating treatment solutions.

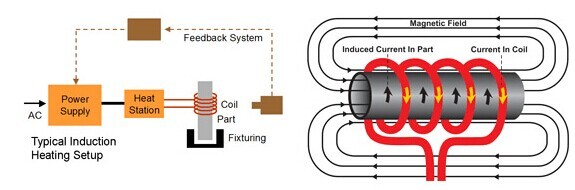

What is induction heating?

Induction heating is a fast,efficient,precise and repeatable heat treatment method for heating metals or other electrically-conductive material.Material is a metal such as steel,iron,brass,aluminum,alloy,copper,stainless steel,tungsten,nickel,precious metals,silver,zinc,gold and etc.or be semiconductor such as silicon carbide,carbon or graphite.

Induction Heater Power Require depends on following factors :

| |||

| » | Mass of work piece

| » | Material properties of work piece |

| » | Temperature increase you require

| » | Heating time require |

| » | Effectiveness of coil design

| » | Comprehensive full load design |

| » | Any heat loss during heating process

| ||

The parameters of the Fast Heating Industrial Induction Heating Machine GYSQ-TC-120AB:

| Model | GYSQ-TC -120AB (Three phase) |

| work power | 340V-430V |

| Maximum input current | 180A |

| Output power | 120KW |

| fluctuating frequency | 10-50khz |

| output current | 400-4000A |

| the flow rate of cooling water | 0.08-0.16Mpa 10L/Min |

| water temperature protection point | 50C |

| product size | main : 770x550x1510mm |

| transformer : 870x430x750 mm | |

| net weight | main : 150gks |

| transformer : 120kgs |

Delivery Time: within 7 workdays.

Shipping Term:By sea,By air,by express.

In the early induction heating equipment, the high frequency inverter equipment required by the inverter unit determines the form of the equipment. From electron tube, thyristor to current universal IGBTs. In the current main stream IGBT-type induction heating products, there are still many differences in-circuits and structures. From the rectifier unit controlled rectification mode and uncontrollable rectification mode; from the perspective of the inverter unit, there are pulse width modulation inverter mode and chopper voltage regulation inverter mode. Parallel resonance from resonant output unit vibration mode and series resonance mode. Various circuits and structures have differences in performance (such as efficiency,power factor, and reliability).

Although using IGBT instead of thyristor Tubes and electronic tubes have made great progress, but most of the induction heating power supply devices developed and produced by manufacturers still have some common problems.

Compared with non-digital products, all-digital products have improved performance in all aspects. This series of products are IGBT or MOSFET inverters, and all adopt DSP Digital precision control, the core control strategy is the reactance analysis method, which can always ensure that the IGBT is ni the ZCS switching state under various working conditions, as to adapt to the inductance and Strong on-site working conditions; multiple operation and control modes and set table functional parameters to make the product meet the requirements various processes needs.

DSP full digital control products, according to different cooling

methods,are divided into two categories: air-cooled and

water-cooled; the internal components of the equipment are composed

of The water circulation takesaway the heat generated by the work

of the components, which is the water-cooled type; and the internal

components of the equipment are cooled by wind energy, which is the

air-cooled type. This type is a new research and development

process.

Induction heating Application:

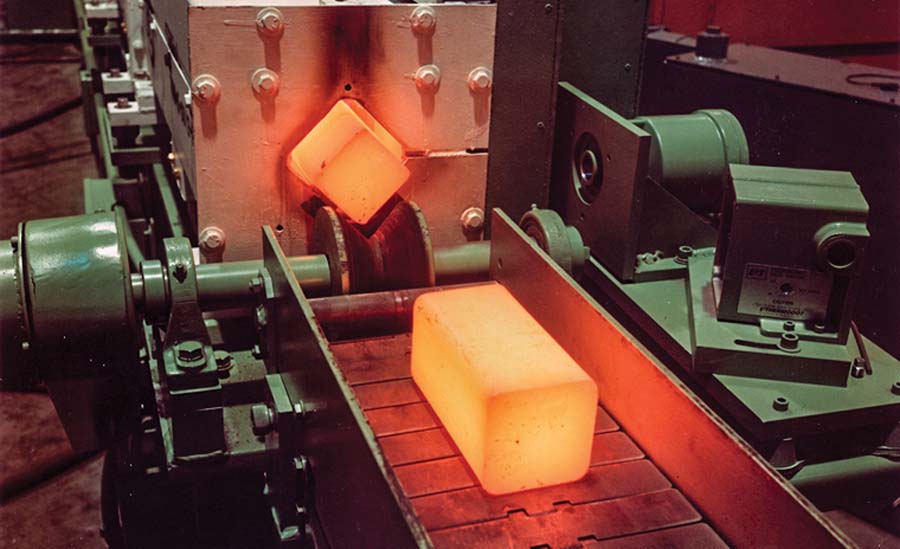

1. Forging

(Bar,flat plate,bar end heating,pipe ends,bar end heating)

2. Pre-heating

(Pipe,steel wire,stainless steel wire)

3. Brazing

(Saw blades,carbide tools,cooper tube,aluminum part,drilling tools,Pan)

4. Annealing

(Steel pipe,golf ball head,brass lock,aluminum pan)

5. Hardening

(Gear,shaft,pipe,bearing,pump fitting,steel plate,roller)

6. Shrink fitting

(motor,pipe)

7. Melting

(Iron,steel,brass,aluminum,silver,zinc)

Q: Why choose GuangYuan Company?

A: We are manufacture which had in this filed for nearly 20

years.No matter quality,price,service,delivery time,we all have

large advantage.

Q:How to choose suiteble machine?

A:You can tell us your application,need

forging,hardening,welding,melting or other,pass me workpiece

material & size,Temperature requirement and heating time

requirement.Then we will recommend fit machine for you reference.

Q:How about the machine delivery time?

A: Small machine delivery time is 3~7 workdays.Big machine delivery

time 15~25 workdays. Normally based on orders.

Q:How about the machine warranty?

A:Our goods support one year warranty not by personal

purpose,support technical service all life.

During the warranty,if machine have problem need change spare

parts,we can replace for you charge free.

Our services

1).Pre-sale service.

1.Inquiry and consulting service

2.recommend the most suitable for our customers according to their

requirements

3.Sample testing support

4.working videos available

5.View our factory

In-sale service.

1. Strictly manufacture the machine, according to relevant

technical standards.

2. Take run test, according to relevant equipment test run

regulations.

3. Strictly check up the machine, before delivery

4. Delivery on time.

After-sale service.

1. Warranty time: 1year Warranty.

2. Within warranty all parts are free for customer, any fault

caused by non-artificial reason, any quality problems such as

design, manufacture, or procedure occurs, We shall provide

replacement parts after detecting the faults.

3. If any big quality problems occurs out of the guarantee period,

we will send maintenance

technician to provide visiting service after checking with the

customer and charge for a favorable price.

5. We will provide a lifetime cost price to the buyer with the

materials and spare parts used in system operation, equipment

maintenance.

6. The above mentioned are only basic aftersale service

requirements,we will make more promises related to quality

assurance and operation guarantee.