Guangyuan Technology (HK) Electronics Co., Ltd. |

|

Verified Suppliers

|

|

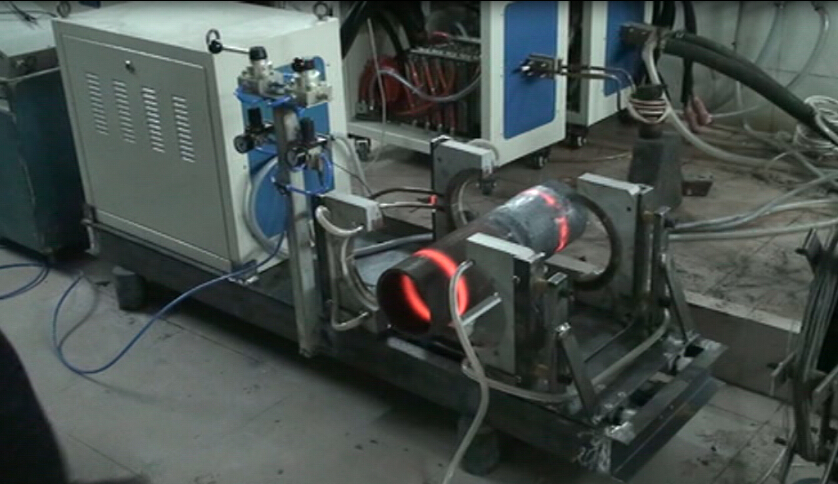

250KW Induction Heat Treatment Machine For Shrink Fitting of Gears, Bears and Rings

INDUCTION HEAT TREATMENT SYSTEM

Induction heat treatment includes induction hardening, induction tempering and induction annealing. Induction heat treatment system combines hardening and temping process with induction heading for high productivity and optimal treat result. Application of induction heat treatments system are chain, bar, screw bar, tube and pipe. Induction Annealing machines mainly be employed in annealing of stainless steel parts,pipes, and other workpieces.

Specification:

| Model | GYMD-250AB (Three phase) |

| Work power | 340V-430V |

| Maximum input current | 375A |

| Output power | 250KW |

| Fluctuating frequency | 1-10KHZ |

| Output current | 400-6500A |

| The flow rate of cooling water | 0.08-0.16Mpa 15L/Min |

| Water temperature protection point | 50C |

| Product size | main : 1090x650x1610mm |

| transformer : 1070x480x850mm | |

| Net weight | main : 258kgs |

| transformer : 178kgs |

Advantages of induction heat treatment machine:

1. Fast heating: the minimum rate of heating is less than 1 second (rate of heating is available for adjustment and control).

2. Wide coverage of heating: it can be used to heat various metal parts (replace removable induction coil as per different operating switches).

3. Easy installation: it can be used once it is connected with power source, induction coil as well as water supply pipe and rising pipe; it is small in size and light in weight.

4. Easy operation: you can learn to operate it within several minutes.

5. Fast start-up: it can be started to perform heating operation on condition that water and power supply is available.

6. Low power consumption: As compared with conventional vacuum tube high frequency equipments, it can save the power by approximately 70%. The smaller the size of the work piece is, the lower power consumption would be.

7. High effectiveness: it has such features as uniform heating (it is applicable to adjust the spacing of the induction coil to ensure the appropriate temperature as required by each part of work piece), fast warming and limited oxic horizon, and can guard against any waste after annealing.

8. Comprehensive protection: it has such functions as overpressure, over-current, overheat and water shortage alarm indications as well as automatic control and protection.

9. Controllable temperature: it is applicable to control the temperature for heating work pieces as per the preset heating time, and thereby control the heating temperature at a certain technical point.

10. Comprehensive full load design: it can work continuously for 24 hours.

11. Small size and light weight: it has a weight of only several dozens of kilograms, of which, the limited floor space can effectively save the workshop space.

12. Elimination of high voltage: it requires no step-up transformer which may produce approximately ten thousand voltage, and thus can ensure the maximum safety.

Shrink fitting refers to the process that inserts or removes a metal component from another. Taking advantage of the thermal expansion principle, the induction heating equipment preheat the workpiece to expand its caliber for insertion or removal process. The joint components will strongly be connected after cooling at ambient temperature.

Induction shrink fitting solution is well-adapted to the practical application. The contact-free induction heating could precisely apply the heating to a small part of the component without impacting the atmosphere.

Induction heating avoids the energy waste on heating irrelevant parts of the component and increase the heating efficiency. As the heat produced by induction shrink fitting equipment is uniformed and accurately targeted to inducted zone, the process is highly controllable. This ensures the tight connection of components and available for employment in flame-free environments.

Induction shrink fitting is broadly applied in industries. The automotive industry is one of the most important applications. Induction shrink fitting solutions well-adapted to the fitting of gears, bears and rings. Furthermore, it is also introduced to the fitting of tubes and pipes, electrical motor etc. Our induction shrink fitting solutions have already served for many clients in mechanical domains.

Our services

Pre-sale service.

In-sale service.

After-sale service.