VAINO INTERNATIONAL LIMITED |

|

high effeciency energy saving injection molding machine with variable pump system

Detailed Product Description

INJECTION PART

High speed and high pressure adopt special injection structure which improve injection speed

The barrel and nozzle of injection setting can be disassembled randomly ,it is easy to maintain

Twin carriage cylinder ensures more even and stable injection .

High quality linear bearing couple ensure smooth and accurate injection

Specific screw and barrel designs are available for processing different material requirements

CONTROL PART

Adopt imported computer which special for injection machine ,its processed and controlled by CPU,This is to expedite response from control system as well as to improve operational accuracy of the machine

Industrial quality components and circuit hardware design provide a stable and reliable control system

Ultra bright LED’S are provide for input and output point inspection providing convenient indication of the machine’s operation and machine servicing .

HYDRAULIC PART

Rexroth variable pump system ,energy saving is more than 30%(V series configuration )

Hydraulic system adopts famous plastic injection molding hydraulic system designed by Germany company

The hydraulic valve are set adjacent to all the oil cylinders for rapid oil transfer

Hydraulic device can choose twice clamping system ,which can meet second-molding product request

Injection part adopts dual nitrogen and cartridge valve’s oil system design ,which improve injection’s high speed performance .

The pre-injection ratio valves control device ,with easy operation and accurate control .

The hydraulic system incorporates control technology from reliable international manufacturers,which accurately control every machine movenment

Injection ,mould close and open are controlled by servo valve is optional ,which improve movement ‘stable and accuracy

SPECIFICATIONS

| SPECIFICATIONS | ||||

| DESCRIPTION | UNIT | K1-220 | ||

| INJECTION | A | B | C | |

| SHOT VOLUME | CM3 | 381 | 470 | 569 |

| SHOT WEIGHT | G | 347 | 429 | 520 |

| (PS) | OZ | 12.1 | 15.0 | 18.1 |

| SCREW DIAMETER | MM | 45 | 50 | 55 |

| INJECTION PRESSURE | MPA | 217 | 176 | 145 |

| SCREW L:D RATIO | 22:1 | 20:1 | 18:1 | |

| SCREW STROKE | MM | 240 | ||

| SCREW SPEED (STEPLESS) | R/MIN | 0~200 | ||

| CLAMPING UNIT | ||||

| CLAMPING FORCE | KN | 2200 | ||

| OPENING STROKE | MM | 480 | ||

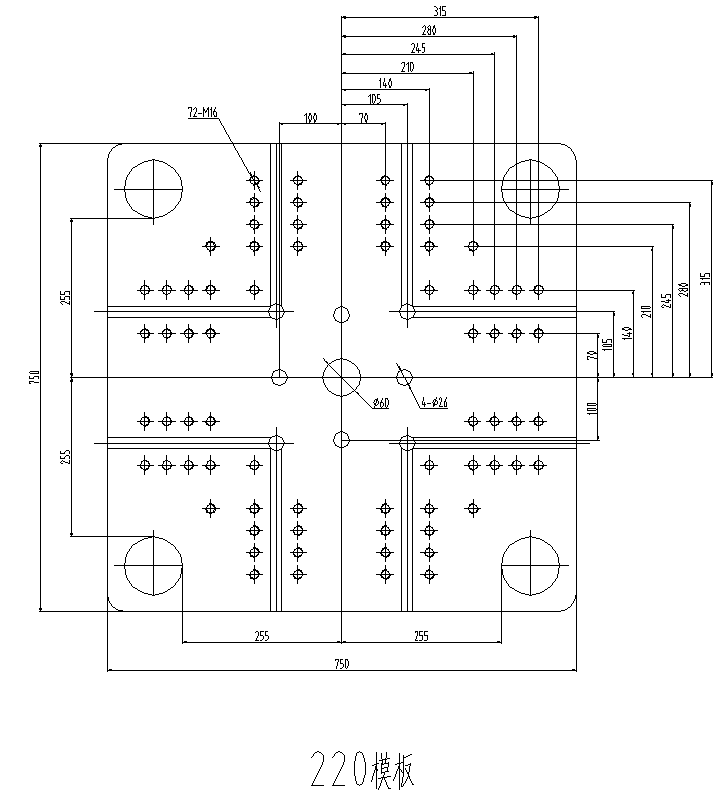

| PLATEN SIZE | MM*MM | 745*745 | ||

| SPACE BETWEEN TIE BARS | MM*MM | 510*510 | ||

| MOLD THICKNESS (MIN-MAX) | MM | 200~560 | ||

| MAX.DAYLIGHT | MM | 1040 | ||

| HYDRAULIC EJECTION STROKE | MM | 150 | ||

| HYDRAULIC EJECTION FORCE | KN | 67 | ||

| POWER UNIT | ||||

| HYDRAULIC SYSTEM PRESSURE | MPA | 17.5 | ||

| PUMP MOTOR(V/S) | KW | 18.5/28.3 | ||

| HEATING CAPACITY | KW | 13.1 | ||

| NUMBER OF TEMP CONTROL ZONES | 4+(NOZZLE ) | |||

| GENERAL | ||||

| DRY-CYCLE TIME | SEC | 4.5 | ||

| OIL TANK CAPACITY | L | 310 | ||

| MACHINE DIMENSIONS | MXMXM | 5.4*1.3*2.1 | ||

| MACHINE WEIGHT | KG | 6800 | ||

HYDRRULICS

Variable displacement pump System

Servo System

Oil suck filiter

Oil temperature control and alarm

By-pass oil filter

ELECTRONICS

8.7' lcd solor screen

200sets of mold memory

Barrel temperature monitoring and thermocouple break alarm

System hardware i/o testing function

Interface for printer and floppy drlver

Electric motor safety protection

Emergency stop safeguard device

RCCESSORIES

Adlustable machine leveling pads

Easily damaged spare parts

Professional tools

Manual

OPTIONRL DEVICE

Wide range of injection unit for specific appliaction

Spacific material screw and barrel

Accumulator fast injection

Core pull fittings

Air blast fittings

Glass water regulations

Extended nozzle