VAINO INTERNATIONAL LIMITED |

|

CE reliable servo injection mold machines with hydraulic oil pump

Detailed Product Description

v

SERVO ENERGY-SAVING DUAL COLOR SERIES INJECTION MOLDING MACHINE

Servo energy-saving dual color series injection molding machine ,according to the two color drinks ,handicraft processing technological requirements,Adopt two group independent feed tube,synchronous do the injection action ,Two color fully fashioned .it can greatly shorten the cycle time and increase the operation profit .

HYDRAULIC PART

Use international brand hydraulic oil pump ,energy-save credibility.stability

High speed and high pressure is controlled by hydraulic system

The pre-injection ratio valves control device ,with easy operation and accurate control .

The hydraulic oil flow design incorporates modular block technology for rapid oil transfer and dynamic system response ,control valves are located in close proximity to each major control group .

Oil pipelines are positioned fro aesthetic appearance and easy of maintenance .

CLAMPING PART

Optimum designed double-toggle five-joint clamping machinery

High rigid mold platen with enlarged space between tie bar

Mold platen with bothT-slot nd mold mounting holes .

Moving platen flowing bearing system ,have raised the efficiency of open /close mold and reduces the energy consumption.

Optimized lubrication system ensuring precision clamping and prolonging the life time of the clamping mechanism

INJECTION PART

High speed and high pressure adopt special injection structure which improve injection speed

The barrel and nozzle of injection setting can be disassembled randomly ,it is easy to maintain

Twin carriage cylinder ensures more even and stable injection .

High quality linear bearing couple ensure smooth and accurate injection

Specific screw and barrel designs are available for processing different material requirements

CONTROL PART

Adopt imported computer which special for injection machine ,its processed and controlled by CPU,This is to expedite response from control system as well as to improve operational accuracy of

SPECIFICATIONS

| SPECIFICATIONS | ||||

| DESCRIPTION | UNIT | K1-170 | ||

| INJECTION | A | B | C | |

| SHOT VOLUME | CM3 | 277 | 318 | 392 |

| SHOT WEIGHT | G | 260 | 298 | 368 |

| (PS) | OZ | 9.1 | 10.5 | 12.9 |

| SCREW DIAMETER | MM | 42 | 45 | 50 |

| INJECTION PRESSURE | MPA | 190 | 166 | 135 |

| SCREW L:D RATIO | 21.5:1 | 20:1 | 18:1 | |

| SCREW STROKE | MM | 200 | ||

| SCREW SPEED (STEPLESS) | R/MIN | 0~200 | ||

| CLAMPING UNIT | ||||

| CLAMPING FORCE | KN | 1700 | ||

| OPENING STROKE | MM | 430 | ||

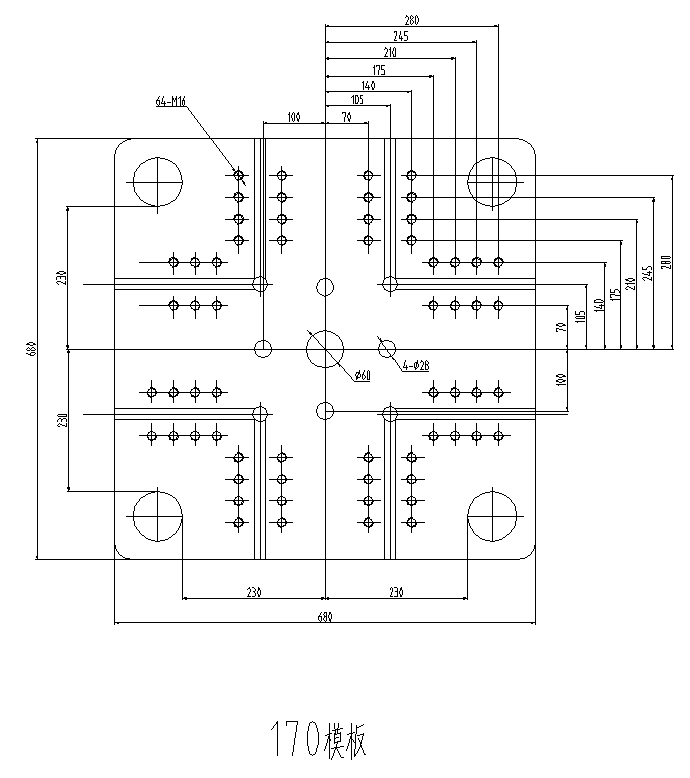

| PLATEN SIZE | MM*MM | 680*680 | ||

| SPACE BETWEEN TIE BARS | MM*MM | 460*460 | ||

| MOLD THICKNESS (MIN-MAX) | MM | 200~530 | ||

| MAX.DAYLIGHT | MM | 960 | ||

| HYDRAULIC EJECTION STROKE | MM | 140 | ||

| HYDRAULIC EJECTION FORCE | KN | 50 | ||

| POWER UNIT | ||||

| HYDRAULIC SYSTEM PRESSURE | MPA | 17.5 | ||

| PUMP MOTOR(V/S) | KW | 15/18.5 | ||

| HEATING CAPACITY | KW | 12.6 | ||

| NUMBER OF TEMP CONTROL ZONES | 4+(NOZZLE ) | |||

| GENERAL | ||||

| DRY-CYCLE TIME | SEC | 2 | ||

| OIL TANK CAPACITY | L | 210 | ||

| MACHINE DIMENSIONS | MXMXM | 4.9*1.2*2.0 | ||

| MACHINE WEIGHT | KG | 5300 | ||

HYDRRULICS

Variable displacement pump System

Servo System

Oil suck filiter

Oil temperature control and alarm

By-pass oil filter

ELECTRONICS

8.7' lcd solor screen

200sets of mold memory

Barrel temperature monitoring and thermocouple break alarm

System hardware i/o testing function

Interface for printer and floppy drlver

Electric motor safety protection

Emergency stop safeguard device

RCCESSORIES

Adlustable machine leveling pads

Easily damaged spare parts

Professional tools

Manual

OPTIONRL DEVICE

Wide range of injection unit for specific appliaction

Spacific material screw and barrel

Accumulator fast injection

Core pull fittings

Air blast fittings

Glass water regulations

Extended nozzle