VAINO INTERNATIONAL LIMITED |

|

Plastic Injection PVC Injection Molding Machine with Servo Motor Save Energy

Detailed Product Description

MZ - D series servo energy - saving

plastic Injection molding machine , More fast

cycle:valve panel design in bigger hole with bigger oil pipe.Oil go

though the valve more fast flow and the Machine action more goes

more faster in mould open and ejector process.

COMPONENT

| COMPONENT | BRAND&ORIGINAL | ||

| hydraulic system | Servo | ||

| hydraulic motor | INTERMOT-ITALY-CHINA | ● | |

| servo motor control system | HUICHUAN/PHASE-CHINA | ● | |

| hydraulic pump | fixed Pump | VICKERS OR YUKEN | / |

| gear pump | SUMITOMO-JAPAN | ● | |

| hydraulic direction valve | NORTHMAN-TAIWAN | ● | |

propotional flow control valve&propotiona l pressure control valve | HNC-TAIWAN FOR BIG MACHINE, SMALL MACHINE USE DONGFENG-CHINA | / | |

| mould adjust hydraulic motor | INTERMOT-CHINA | ● | |

| hydraulic safety valve | NORTHMAN-TAIWAN | ● | |

| electric system | |||

| computer/controller | TECHMATION-TAIWAN | ● | |

| relay | SCHNEIDER-GERMANY | ● | |

| main switch | LS-KOREA | ● | |

| linear transducer | GEFRAN-ITALY | ● | |

| limited switch | PANASONIC-JAPAN | ● | |

| breaker | CHENTAI-CHINA | ● | |

| electric motor | ZHONGDA-CHINA | / | |

| others | |||

| High pressure hydraulic pipe | GOODYEAR-USA | ● | |

| seals | VALQUA-JAPAN | ● | |

| pressure meter | Tecsis-USA | ● | |

| automatic lubrication | SL-CHINA | ● | |

| screw | JINGXING-CHINA 38CrMoAlA | ● | |

SPECIFICATION

| SPECIFICATION | M-560 | ||||

| ITEM | A | B | C | D | |

| INJECTION UNIT | |||||

| SCREW DIAMETER | mm | 75 | 80 | 85 | 90 |

| SCREW L/D RATIO | L/D | 23 | 22 | 21 | 19.5 |

| SHOT VOLUME(THEORETICAL) | ㎤ | 1811 | 2061 | 2327 | 2608 |

| INJECTION WEIGHT(PS) | g | 1666 | 1896 | 2140 | 2400 |

| INJECTION PRESSURE | Mpa | 190 | 168 | 148 | 132 |

| INJECTION RATE | g/sec | 306 | 348 | 393 | 441 |

| SCREW SPEED | rpm | 160 | |||

| CLAMPING UNIT | |||||

| CLAMP TONNAGE | KN | 5600 | |||

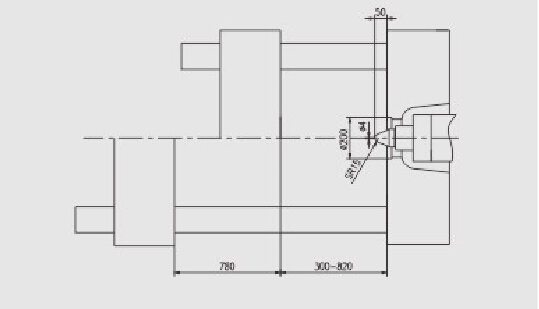

| TOGGLE STROKE | mm | 780 | |||

| MIN.MOLD HEIGHT | mm | 300 | |||

| MAX.MOLD HEIGHT | mm | 820 | |||

| SPACE BETWEEN TIE BARS | mm | 830X780 | |||

| EJECTOR TONNAGE | KN | 120 | |||

| EJECTOR STROKE | mm | 230 | |||

| EJECTOR NUMBER | PC | 13 | |||

| OTHERS | |||||

| MAX.PUMP PRESSURE | Mpa | 16 | |||

| HEATER POWER | KW | 32 | |||

| PUMP MOTOR POWER | KW | 45 | |||

| OIL TANK CUBAGE | L | 700 | |||

| MACHINE DIMENSION(LxWxH) | M | 8.15X1.95X2.5 | |||

| MACHINE WEIGHT | T | 17.5 | |||

Machines feature

High enery saving

In an ideal working state , compared with conventional inject molding machines , their energy saving can reach 20%-80%.

Material charging more faster

Adopt proportional control for backpressure,can be set in the controller ,more smart and easy operation.when material charging,you can set 0 in the backpressure,so the charging will be more efficient and faster.make sure every shot to be more accurate than manual control type.

Double oil tank design

because short the distance for the oil return line ,the hydraulic system response is getting more quicker. In the meantime,this design will reduce the oil temperaure ,protect the oil seal.