Shenzhen Omini Technology Co.,Ltd |

|

Verified Suppliers

|

|

Immersion Gold 10U'' Copper Base PCB For Precision Communication Equipment

Quick details:

Base Material: Copper

Copper Thickness: 3oz

Board Thickness: 2.4 mm

Min. Hole Size: 12 mil

Min. Line Width: 4 mil

Min. Line Spacing: 4 mil

Surface Finishing: Immersion silver/Gold Finger/Immersion Tin/ENIG/ENEPIG

Board Size: Customize Min:6mm*6mm Max:457mm*610mm

Application: Lighting, Automotive, Power supply, Precision Communication Equipment

Sheet thickness: 0.1mm-7mm

Maximum board width: Customize

Type: Copper base PCB

Certificate: TS16949.ISO14001.ROHS. ISO9001

Color: Green, White, Blue, Black, Red, Yellow

Package: Vacuum packing

Description of Copper PCB Printed Circuit Board Advantage:

1. Advantages of thermal conductivity

Under the same conditions:

Aluminum base: about 200 W/M.K.

Copper base: about 400 W/M.K.

From the thermal conductivity, we can intuitively see the heat

dissipation advantage of the metal copper substrate over the

aluminum substrate.

2. Advantages of PCB processability

(1) Since the metal copper base can be etched with fine patterns by

etching lines, the copper substrate can be processed into a boss

shape, so that it protrudes to the wiring layer or the surface of

the patch is flush with the surface of the patch, and the

components can be directly Paste on the boss to achieve excellent

grounding and heat dissipation effects;

(2) Due to the PCB processing technology itself, it is impossible to directly realize metallization on the aluminum base (such as single-sided aluminum substrate), while the copper base can be processed into metallized holes, so that the corresponding single-sided or multi-layer backplane It has excellent optional grounding performance, and secondly, copper itself has solderability, so that the final installation of the designed structural parts can be selected for welding, which is much better than the heat dissipation effect of using heat sinks.

(3) Due to the difference in elastic modulus between copper and aluminum (the elastic modulus of copper is about 121000MPa, and the elastic modulus of aluminum is 72000MPa), the corresponding warpage and expansion of the copper substrate will be smaller than that of the aluminum substrate, and the overall performance more stable.

Specification of Omini High Frequency PCB Printed Circuit Board:

| Layer | 2-24 layer |

| Material | Copper |

| Board thickness | 0.4mm-5.0mm |

| Max.finished board side | 457mm*610mm |

| Min.drilled hole size | 0.25mm |

| Min.line width | 0.075mm(3mil) |

| Min.line spaceing | 0.075mm(3mil) |

| Surface finish/treatment | Electroless/immersion gold/ENIG/Immersion silver/Organic solderability |

| Copper thickness | 1oz - 8oz |

| Solder mask color | green/black/white/red/blue/yellow |

| Inner packing | Vacuum packing, Plastic bag |

| Outer packing | Standard carton packing |

| Hole tolerance | PTH:±0.076, NTPH:±0.05 |

| Certificate | UL, ISO9001, ISO14001, RoHS, CQC |

| Profiling Punching | Routing, V-CUT, Beveling |

| Assembly Service | Providing OEM service to all sorts of printed circuit board assembly |

FAQ:

Q1:Does Omini have enough capacity to prodece high-quality products?

A: Omini has 20 years of history in manufacturing PCB, more than 200 employees and 10,000㎡ factory area.We got the UL, ISO9001 certificates, and our production is sold abroad. We have engouh machines & equipment to ensure the quality, please check our Production Equipment list picturers.

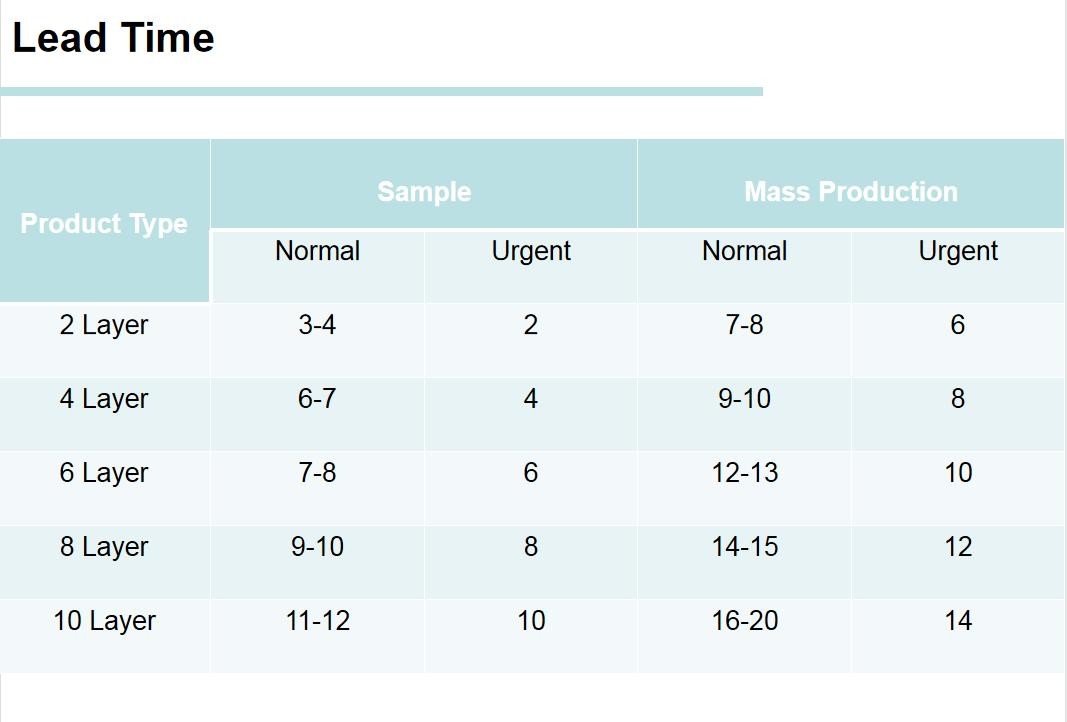

Q2:How long does customers need to wait for the quotation and lead time?

A: We have a prefessional group to deal with your inquiry. In our working time, we will reply to your email within 30 minutes to show we have received your inquiry, Then we will send you our quotation in no more than 6 hours. Please noticed our working time is Monday to Friday, 8am to 24pm.

Q3:How can I make sure my PCB gerber is safety?

A: We promise we won't divulge your gerber to the 3rd party, one of our responsibilities is protecting customer information privacy and security, customer information can be included: company name, address, number, trademark, ect. And we could sign NDA with client if necessary.