Dongtai Yaoqiang machinery Co.,Ltd |

|

Specification:

The cut material plate is fed into abdominal cavity, only to press

the button, it can work till the material formed into finished

steel one time. During the process, manual interference is reduced.

The production efficiency improved highly and equipment cost and

manpower cost reduced, and equipment installation room also saved.

It is the most efficient steel H beam and T beam production

equipment.

Supply scope:

Assembling machine: Main transmission parts, web clamp, flange

clamp, upper gate press device, hydraulic alignment device, drag

bar centralizing system, inlet table roller, outlet table roller,

hydraulic system unit and etc.

Gantry gate welding machine: Double screw welding gun adjusting

device, welding gun lean tracking device, welding gun clamping

device, flux automatic recovery and transmission machine, MZ-1000S

double screw and double arc sub merge arc welding machine(domestic

and imported optional) and etc.

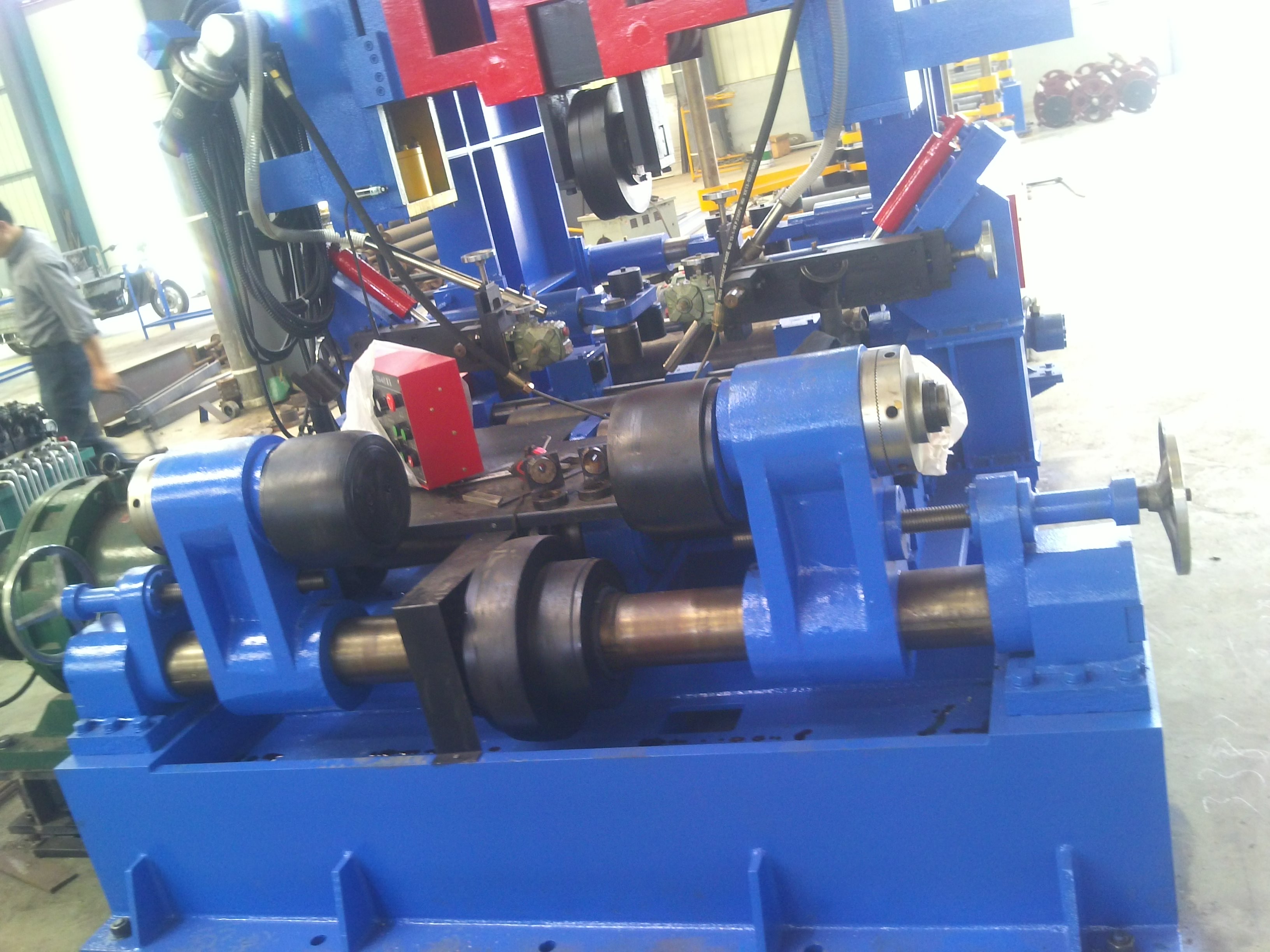

Flange straightening machine: Straightening assistant supporting

wheel unit, flange left and right clamping unit, hydraulic clamping

left and right stretching out and drawing back straightening wheel

unit and etc.

Electric control system: Electrical cabinet, AC frequency

converter, PLC programming controller and etc.

Spare parts: 5PCS buttons, 4PCS HH54PDC24V electric relay, 6PCS

each 4A and 6A molten core.

| Model | web height | web thickness | welding and straightening speed | flange width | flange thickness | overall power |

| YQPJ1000 | 1000mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

| YQPJ1200 | 1200mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

| YQPJ1500 | 1500mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

1. The main assembly unit adopts the heavy duty assembly machine

patent which has been submitted for approval. The web and flange

are positioned automatically, with highly improved accuracy and

efficiency.

2. The endurable welding guns fix device can adjust height as well

as horizontal move place. It can also adjust the welding guns angle

from 2 positions. So the welding seam can be nice and neat.

3. Assisting straightening part has unique design. The two

straightening wheels could actively straighten the work piece under

cylinder drive. From the straightening device, the user can see

clearly the welding seam, easy for welding gun position adjustment

and observation of welding seam.

4. The main assembly unit together with assistant straightening

unit could be used as assembly-weld machine or assembly machine

separately.

5. After modification, the straightening unit could be used as mini

straightening machine.

| NO. | MODEL | YQPJ1500 |

| 1 | Web height | 1500 mm |

| 2 | Web thickness | 6~32 mm |

| 3 | Flange width | 150~800 mm |

| 4 | lange thickness | 6-40 mm |

| 5 | H beam length | 4000~15000 mm |

| 6 | Dimensional adjustment system | Separate, mechanical |

| 7 | welder | 2 sets of Mechanical submerged arc welding machine |

| 8 | Welder Power | 2×75KW |

| 9 | Welder type | automatic submerged arc welding |

| 10 | weld speed | 0-1000 mm/min |

| 11 | Weld speed adjustment | level and smooth |

| 12 | Head angle adjustment | ±45°±12.5 |

| 13 | Pressure of hydraulic system | ≤10 Mpa |

| 14 | Automatic welding cycle system | 2sets |

| 15 | Flux | 2×100 kg |

| 16 | Total power | 24 kw Except for welding power supply |

| 17 | Overall dimensions (L * w * h) | 30000×3270×5150 mm |

| weld size(mm) | wire diameter(mm) | welding current (A) | welding voltage(V) | welding speed(mm/min) |

| 4 | 3 | 350~370 | 28~30 | 880~910 |

| 6 | 3 | 450~470 | 28~30 | 900~960 |

| 4 | 480~500 | 28~30 | 960~1000 | |

| 8 | 3 | 500~530 | 30~32 | 730~760 |

| 4 | 670~700 | 32~34 | 800~830 |

| No. | Name | |

| 1 | welder | MZ-1000(optional,also can use CO2 welder) |

| 2 | Welding machine control box | MZ-1000 |

| 3 | Inverter manufacturers | 11KW,2.2KW HUICHUAN |

| 4 | Major electrical equipment manufacturers | SIEMENS, OMRON (Japan) |

| 5 | Hydraulic parts manufacturers | TAIWAN |

| 6 | main motor supplier | NANTONG |

| 7 | Wing web centering motor | 2 sets NINGBO |

| 8 | Main reducer manufacturers | CHANGZHOU |

| 9 | recovery equipment | 2 sets WUXI |

Supply matching:

Frame;

Console;

Pre assembled mechanism;

Feed roller table;

Delivery roller table;

2 sets of welding machine;

Hydraulic station;

Mushroom shaped deformation correcting mechanism for beam;

Welding console -2 sets for wire feed mechanism;

Wire box -2 parts;

Hydraulic hose;

Flux cycle system ----2 set;

Work platform and ladder;