Dongtai Yaoqiang machinery Co.,Ltd |

|

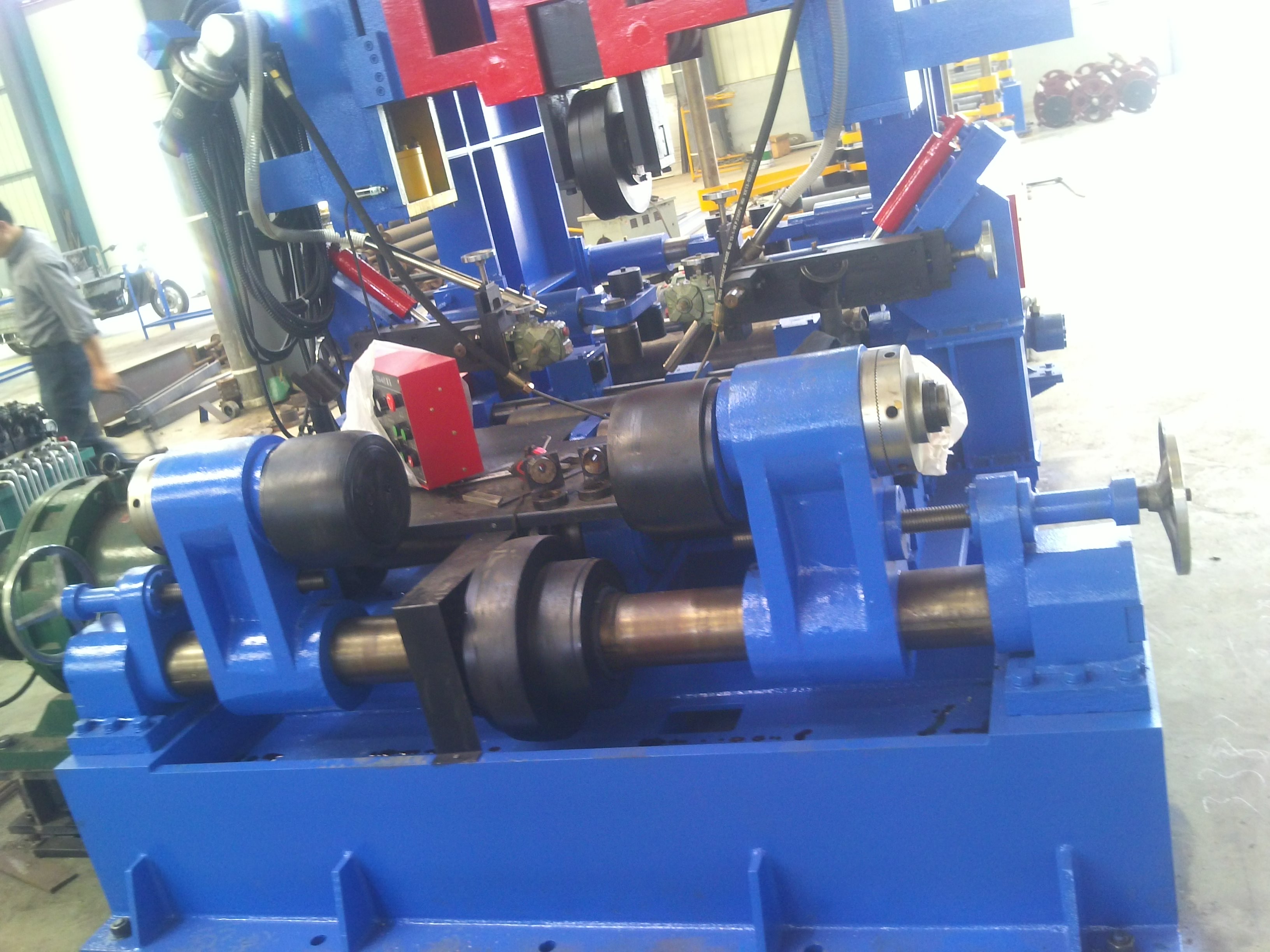

YQPJ1500 CE Certificate Auto Assembly-Welding-Straightening 3 in 1 Intergrated Machine for H Beam with MZ1250 welder

Product Description

This machine is suitable for use in the workplace, less affordable,

comprehensive functions. It includes 3 main steps: H beam

manufacturing assembly - Welding - correction. It can be symmetric

and non symmetric section production H type and T type beam. It

also can complete the following steps: the initial beam assembly

and final assembly, welding submerged arc butt beam in the vertical

state, the welding deformation of the beam (mushroom) correction.

Automatic assembly machine is equipped with.H type assembly solder

circulating system to reduce the consumption of the beam and

welding flux for automatic production mode. By adjusting the speed

of the beam in the program monitor, so as to ensure the quality of

welding seam.

Specification:

The cut material plate is fed into abdominal cavity, only to press

the button, it can work till the material formed into finished

steel one time. During the process, manual interference is reduced.

The production efficiency improved highly and equipment cost and

manpower cost reduced, and equipment installation room also saved.

It is the most efficient steel H beam and T beam production

equipment.

Composition:

1.Main machine: including H steel assembly, welding, straightening,

roller conveying and so on.

2.Electrical control system: main control cabinet, set the PLC

program system, touch screen display lamp

3.Erecting mechanism: Web clamping, wing plate clamping, lower

pressing device

4.Lifting mechanism: inputting roller table device;

5.The discharging mechanism (including lifting mechanism 2):

outputting roller table device;

6.Hydraulic system: oil cylinder, hydraulic pump station,

high-pressure oil pipe lamp

7.Alignment mechanism: cylinder lifting device

8.Wire feeding mechanism assembly:

9.Work platform and escalator: accessories and so on

10.Welding power supply two: power supply, control box, welding

cable, control cable and so on

11.Flux recovery device two sets: whirlpool pump, recovery device,

funnel, etc.

Technical Parameters

| Model | web height | web thickness | welding and straightening speed | flange width | flange thickness | overall power |

| YQPJ1000 | 1000mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

| YQPJ1200 | 1200mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

| YQPJ1500 | 1500mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

| NO. | MODEL | YQPJ1500 |

| 1 | Web height | 1500 mm |

| 2 | Web thickness | 6~32 mm |

| 3 | Flange width | 150~800 mm |

| 4 | lange thickness | 6-40 mm |

| 5 | H beam length | 4000~15000 mm |

| 6 | Dimensional adjustment system | Separate, mechanical |

| 7 | welder | 2 sets of Mechanical submerged arc welding machine |

| 8 | Welder Power | 2×75KW |

| 9 | Welder type | automatic submerged arc welding |

| 10 | weld speed | 0-1000 mm/min |

| 11 | Weld speed adjustment | level and smooth |

| 12 | Head angle adjustment | ±45°±12.5 |

| 13 | Pressure of hydraulic system | ≤10 Mpa |

| 14 | Automatic welding cycle system | 2sets |

| 15 | Flux | 2×100 kg |

| 16 | Total power | 24 kw Except for welding power supply |

| 17 | Overall dimensions (L * w * h) | 30000×3270×5150 mm |

| weld size(mm) | wire diameter(mm) | welding current (A) | welding voltage(V) | welding speed(mm/min) |

| 4 | 3 | 350~370 | 28~30 | 880~910 |

| 6 | 3 | 450~470 | 28~30 | 900~960 |

| 4 | 480~500 | 28~30 | 960~1000 | |

| 8 | 3 | 500~530 | 30~32 | 730~760 |

| 4 | 670~700 | 32~34 | 800~830 |

| No. | Name | |

| 1 | welder | MZ-1000(optional,also can use CO2 welder) |

| 2 | Welding machine control box | MZ-1000 |

| 3 | Inverter manufacturers | 11KW,2.2KW HUICHUAN |

| 4 | Major electrical equipment manufacturers | SIEMENS, OMRON (Japan) |

| 5 | Hydraulic parts manufacturers | TAIWAN |

| 6 | main motor supplier | NANTONG |

| 7 | Wing web centering motor | 2 sets NINGBO |

| 8 | Main reducer manufacturers | CHANGZHOU |

| 9 | recovery equipment | 2 sets WUXI |

Supply matching:

Frame;

Console;

Pre assembled mechanism;

Feed roller table;

Delivery roller table;

2 sets of welding machine;

Hydraulic station;

Mushroom shaped deformation correcting mechanism for beam;

Welding console -2 sets for wire feed mechanism;

Wire box -2 parts;

Hydraulic hose;

Flux cycle system ----2 set;

Work platform and ladder;

The supply does not include:

1. foundation;

2. connect to the power and air source of the equipment;

3. equipment grounding;

4. welding wire or flux etc.