Zhengzhou Huitong Pipeline Equipment Co.,Ltd. |

|

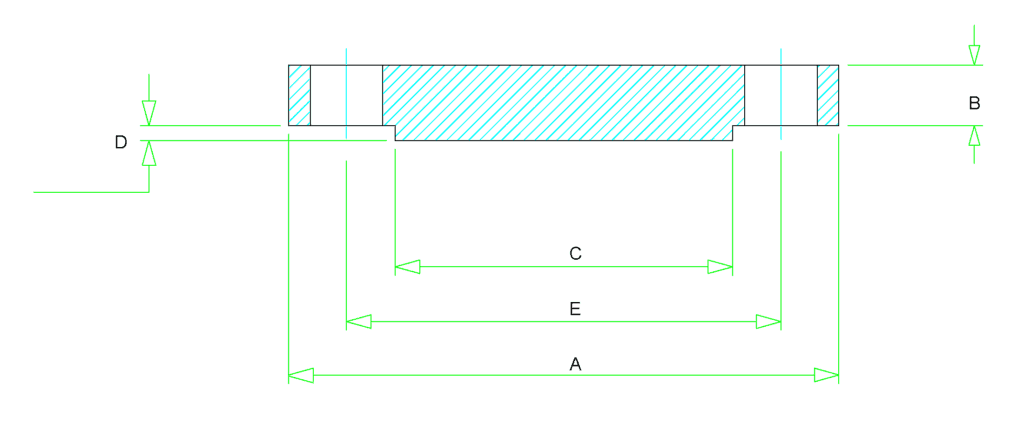

Carbon Steel Pipe Flange Smooth Surface 2500# 1/2" - 24" ASTM B16.5

1. Flange Specification:

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | ||||||||

| 1/2 | 15 | 135 | 30.2 | 34.9 | 7 | 88.9 | 4 | 3/4 | 120 | 7/8 | M20 | 3.2 |

| 3/4 | 20 | 140 | 31.8 | 42.9 | 7 | 95.2 | 4 | 3/4 | 125 | 7/8 | M20 | 3.7 |

| 1 | 25 | 160 | 35 | 50.8 | 7 | 108 | 4 | 7/8 | 140 | 1 | M24 | 5 |

| 1 1/4 | 32 | 185 | 38.1 | 63.5 | 7 | 130.2 | 4 | 1 | 150 | 1 1/8 | M27 | 7.8 |

| 1 1/2 | 40 | 205 | 44.5 | 73 | 7 | 146 | 4 | 1 1/8 | 170 | 1 1/4 | M30 | 10.5 |

| 2 | 50 | 235 | 50.9 | 92.1 | 7 | 171.4 | 8 | 1 | 180 | 1 1/8 | M27 | 18 |

| 2 1/2 | 65 | 265 | 57.2 | 104.8 | 7 | 196.8 | 8 | 1 1/8 | 195 | 1 1/4 | M30 | 25.5 |

| 3 | 80 | 305 | 66.7 | 127 | 7 | 228.6 | 8 | 1 1/4 | 220 | 1 3/8 | M33 | 39 |

| 4 | 100 | 355 | 76.2 | 157.2 | 7 | 273 | 8 | 1 1/2 | 255 | 1 5/8 | M39 | 61.5 |

| 5 | 125 | 420 | 92.1 | 185.7 | 7 | 323.8 | 8 | 1 3/4 | 300 | 1 7/8 | M45 | 102 |

| 6 | 150 | 485 | 108 | 215.9 | 7 | 368.3 | 8 | 2 | 345 | 2 1/8 | M52 | 157 |

| 8 | 200 | 550 | 127 | 269.9 | 7 | 438.2 | 12 | 2 | 380 | 2 1/8 | M52 | 241 |

| 10 | 250 | 675 | 165.1 | 323.8 | 7 | 539.8 | 12 | 2 1/2 | 490 | 2 5/8 | M64 | 470 |

| 12 | 300 | 760 | 184.2 | 381 | 7 | 619.1 | 12 | 2 3/4 | 540 | 2 7/8 | M72 | 575 |

2.Carbon Steel

Carbon steel is a steel with carbon content up to 2.1% by weight.

The term "carbon steel" may also be used in reference to steel which is not stainless steel; in

this use carbon steel may include alloy steels.

As the carbon percentage content rises, steel has the ability to become harder and stronger

through heat treating; however, it becomes less ductile. Regardless of the heat treatment, a

higher carbon content reduces weldability. In carbon steels, the higher carbon content lowers

the melting point.

AISI classification

Carbon steel is broken down into four classes based on carbon content:

Low-carbon steel

0.05 to 0.30% carbon (plain carbon steel) content.

Medium-carbon steel

Approximately 0.3–0.6% carbon content.Balances ductility and strength and has good wear

resistance; used for large parts, forging and automotive components.

High-carbon steel

Approximately 0.60 to 1.00% carbon content.Very strong, used for springs, edged tools, and high-

strength wires.

Ultra-high-carbon steel

Approximately 1.25–2.0% carbon content.Steels that can be tempered to great hardness. Used for

special purposes like (non-industrial-purpose) knives, axles or punches. Most steels with more than

2.5% carbon content are made using powder metallurgy.

3.Carbon Steel Flange Packaging

Carbon Steel Flanges are widely used in various industries including petrochemical, oil and gas,power

generation, bulk liquid transportation, chemicals, pharmaceuticals, pulp and paper manufacturing,

textiles and others. All our Carbon Steel Flange are manufactured in accordance with international

standards. Carbon Steel Flanges are packaged to ensure that there is no damage during transit.In case

of exports, standard export packaging is done in wooden cases. All Carbon Steel Flanges are marked

with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make custom

marking on Carbon Steel Flanges.

4.Delivery:

Port:

Tianjin/Shanghai/Ningbo

Lead Time :

| Quantity(Pieces) | 1 - 100 | >100 |

| Est. Time(days) | 15-30 | To be negotiated |

5.Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of

boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce

or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204

3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record,

WPS/PQR

• Form A for the purposes of the Generalized System of Preferences

(GSP)