Zhengzhou Huitong Pipeline Equipment Co.,Ltd. |

|

1.INCONEL Alloy 601 Overview:

INCONEL nickel-chromium-iron alloy 601 (UNS N06601/W.Nr. 2.4851) is a general-purpose engineering material for applications that require resistance to heat and corrosion. An outstanding characteristic of INCONEL alloy 601 is its resistance to hightemperature oxidation. The alloy also has good resistance to aqueous corrosion, has high mechanical strength, and is readily formed, machined and welded. The composition is a facecentered-cubic solid solution with a high degree of metallurgical stability. The alloy's nickel base, in conjunction with substantial chromium content, provides resistance to many corrosive media and hightemperature environments. Oxidation resistance is further enhanced by the aluminum content.

Elementary composition :

| Ni | Cr | C | Mn | Si | S | Fe | |

| Max | 63 | 25 | 0.1 | 1 | 1 | 0.015 | Bal |

| Min | 58 | 21 |

Mechanical Properties:

| Ultimate Tensile | Yield Strength (0.2% OS) | Elong. in 2 in., or 50mm or 4D, min., % | R/A | Hardness | |

| Cold Worked/Annealed | |||||

| Min | 80 KSi | 30 KSi | 30 | ||

| Max | |||||

| Min | 550 MPa | 205 MPa | |||

| Max | |||||

| Hot Worked/Annealed | |||||

| Min | 80 KSi | 30 KSi | 30 | ||

| Max | |||||

| Min | 550 MPa | 205 MPa | |||

| Max | |||||

Specifications:

| Form | Standard |

| Metal Type | UNS N06601 |

| Bar | ASTM B166 Din 17752 |

| Wire | |

| Sheet | ASTM B168 Din 17750 |

| Plate | ASTM B168 Din 17750 |

| Fitting | |

| Forging | Din 17754 |

| Weld Wire | FM 82 |

| Weld Electrode | FM 617 |

| Din | 2.4851 |

Characteristics:

The most important property of Inconel 601 is resistance to oxidation at very high temperatures up to 1250C. Even under severe conditions such as, cyclical heating and cooling. This is possible due to Inconel 601 having a tightly adherent oxide layer which is resistant against spalling.

Resistance to carburization is good, also resistant to carbon nitriding conditions.

Due to high chromium and some aluminum content, good resistance in oxidizing sulfur bearing atmospheres at elevated temperatures is demonstrated.

2.Regular packaging Inconel 601 ASTM B474 UNS6601 pipe:

Woven

Wooden:

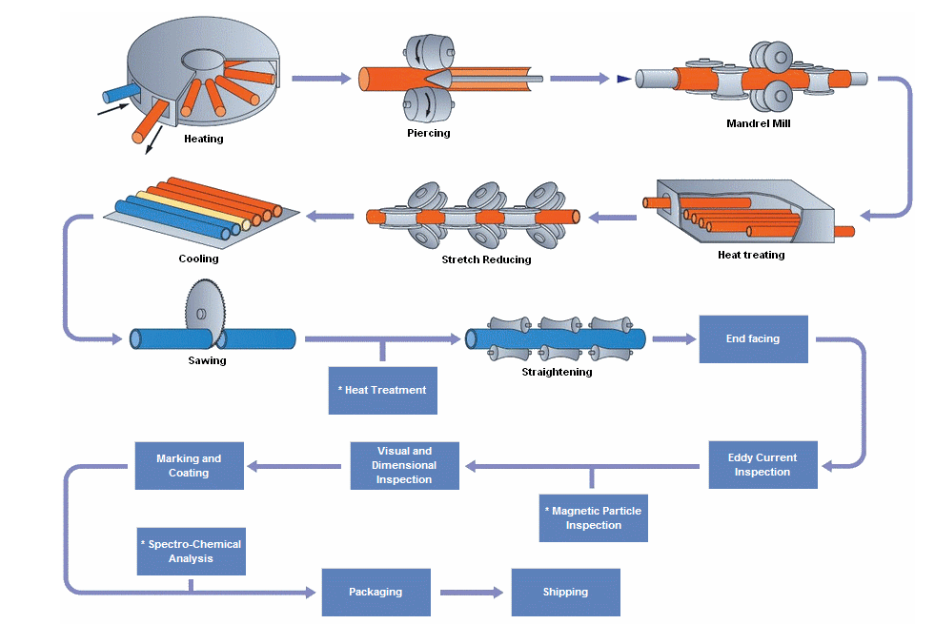

3.Process for Inconel 601 ASTM B474 UNS6601 pipe:

4.Fabrication and Heat Treatment for INCONEL Alloy 601:

Inconel 601™ is formed using all conventional techniques.

Inconel 601™ is welded using gas-tungsten arc welding, gas metal-arc welding, shielded metal-arc welding, and submerged-arc welding methods.

Inconel 601™ does not respond to heat treatment.

Inconel 601™ is forged at 1038 to 1233°C (1900 to 2250°F)

Inconel 601™ is hot worked at 872 to 1233°C (1600 to 2250°F)

Inconel 601™ can be cold formed using standard tooling.

Inconel 601™ is annealed at 1149°C (2100°F). It is then cooled at temperatures ranging from 538 to 760°C (1000 to 1400°F) in order to prevent thermal cracking.

Inconel 601™ can be hardened only by cold working.