Zhengzhou Huitong Pipeline Equipment Co.,Ltd. |

|

1. Corrosion resistant ASTM B462 Alloy 20 Carpenter 20Cb3 N08020 Hex Nipples Pipe Nipples Bosses as per BS3799

Alloy20 forged hex nipple, Alloy20 pipe nipples, Alloy20 bosses Manufacturer and Suppliers In China.

Alloy UNS N08020 Bosses Hex Nipple Pipe Nipple Exporter, Carpenter 20Cb3 bosses hex nipple pipe nipple Exporter in China.

2. Specification for Corrosion resistant ASTM B462 Alloy 20 Carpenter 20Cb3 N08020 Hex Nipples Pipe Nipples Bosses as per BS3799

| Specifications | ASTM B462 & ASME B462 |

| Size | 1/8” NB to 6” NB |

| Class Rating | 3000LB 6000LB |

| Standards | BS3799 |

| Type | Bosses Hex Nipple Pipe Nipple |

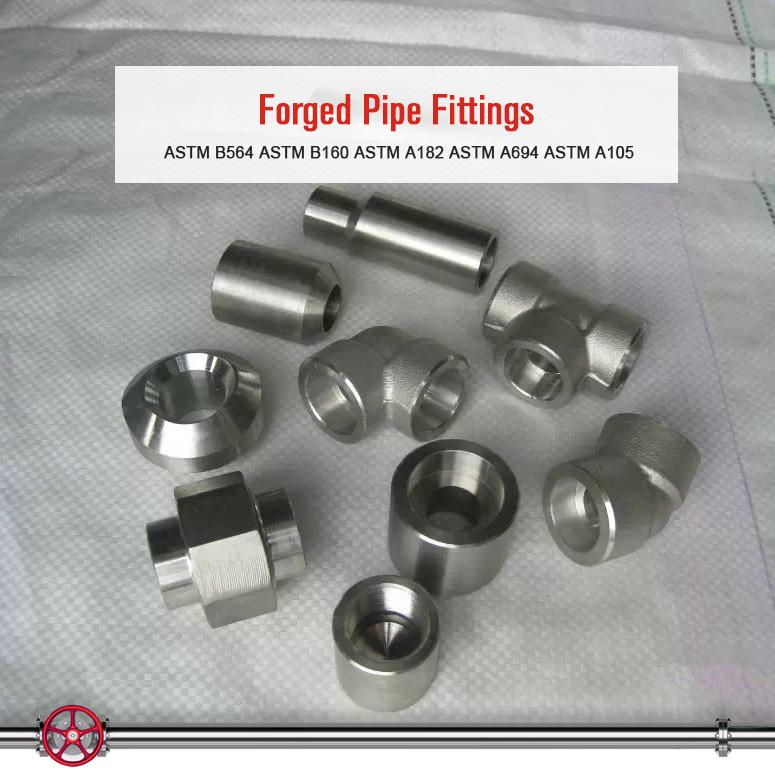

3. Other Forged Pipe Fittings We have:

| Standard | Types | Class Rating/Schedule | Ends | Size |

| ASME B16.11 | 90°Elbow/ 45°Elbow/ Tee/ Cross | 2000LB | Threaded | 1/4''~4'' |

| 90°Elbow/ 45°Elbow/ Tee/ Cross/Pipe Cap/ Half Coupling/Full Coupling | 3000LB/6000LB | Threaded | 1/4''~4'' | |

| Socket-welding | 1/8''~4'' | |||

| 90°Elbow/ 45°Elbow/ Tee/ Cross/Half Coupling/Full Coupling | 9000LB | Socket-welding | 1/2''~2'' | |

| Street Elbow | 3000LB | Threaded | 1/8''~2'' | |

| 6000LB | 1/8''~1-1/2'' | |||

| Lateral Tee | 3000LB | Socket-welding | 1/4''~2'' | |

| 6000LB | 1/2''~1-1/2'' | |||

| 3000LB | Threaded | 3/8''~2‘’ | ||

| 6000LB | 1/2''~2'' | |||

| 9000LB | 1/2''~1-1/2'' | |||

| Flush Bushing/Hex Bushing/Hex Plug/Round Plug/Square Plug | 3000LB/6000LB | Threaded | 1/8''~4'' | |

| MSS SP79 | Reducer Inserts | 3000LB/6000LB/9000LB | Socket-welding | 3/8‘’x1/4''~2x1/2'' |

| MSS SP83 | Union | 3000LB | Socket-welding/Threaded | 1/8''~3'' |

| MSS SP95 | Concentric/Eccentric Swaged Nipples | See Below Note1 | 1/4‘’~12'' | |

| Bull Plugs | Threaded | 1/8''~12'' | ||

| MSS SP97 | Weldolet | STD, XS, Sch 160/XXS | Butt-welding | 1/8''~36‘’ or larger |

| Sockolet | 3000LB/6000LB | Socket-welding | 1/8''~6'' | |

| Threadolet | 3000LB/6000LB | Threaded | 1/8''~6'' | |

| Nipolet | XS/XXS | Plain/Threaded | 1/2''~2'' | |

| Elbolet | 3000LB/6000LB | Socket-welding/Threaded | 1/4''~2'' | |

| STD/XS/160/XXS | Butt-welding | 1/4''~2-1/2'' or larger | ||

| Latrolet | 3000LB/6000LB | Socket-welding/Threaded | 1/2''~2'' | |

| STD/XS/160/XXS | Butt-welding | 1/2''~2-1/2'' | ||

| Flangolet,Nipolet,Sweepolet,etc. available as per client' demands. | ||||

| BS3799 | Hex Nipple | 3000LB/6000LB | Threaded | 1/8''~2''x1/2'' |

| Bosses | 3000LB | Threaded | 1/8''~2'' | |

| 6000LB | Threaded | 1/8''~4'' | ||

| Pipe Nipple | 40/STD/80/XS /160/XXS | See Below Note1 | 1/8''~6'' | |

| Material Grade | Nickel Alloy | ASTM / ASME B/SB 564 UNS N02200 (NICKEL200), UNS N04400 (MONEL 400), UNS N08825(INCOLOY825), UNS N06600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS N06625 (INCONEL 625), UNS N10276 ( HASTELLOY C 276), ASTM / ASME B/SB 160 UNS N02201 (NICKEL 201) ASTM / ASME B/SB 472 UNS N08020 ( ALLOY20 / 20CB3) | ||

| Copper Alloy | ASTM / ASME B/SB 151 UNS C70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30) | |||

| Stainless Steel | ASTM / ASME A/SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H. | |||

| Duplex and Super Duplex Steel | ASTM / ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61,F904L | |||

| Carbon Steel | ASTM / ASME A/SA 105(N) | |||

| Low Temp Carbon Steel | ASTM / ASME A/SA 350 LF 2. | |||

| High Yield Carbon Steel | ASTM / ASME A/SA694 F52 F56 F60, F65, F70 | |||

| Alloy Steel | ASTM / ASME A182 GR F5, F9, F11, F12, F22, F91. | |||

| Titanium | ASME ASTM SB/B381 Grade 2, Grade 5, Grade 7 | |||

| Note1 | PBE:Plain Both Ends BBE Bevel Both Ends TBE: Threaded Both Ends PSE:Plain Small End BSE:Bevel Small End TSE:Threaded Small End PLE:Plain Large End BLE:Bevel Large End TLE:Thread Large End | |||

| Note2 | For the swage nipples,pipe nipples,the material can be referred to the pipe standard. | |||

| Note3 | NPT(National Pipe Thread) FPT(Female Pipe Thread) MPT(Male Pipe Thread) BSPT(British Standard Pipe Thread) | |||

4. Types of Corrosion resistant ASTM B462 Alloy 20 Carpenter 20Cb3 N08020 Hex Nipples Pipe Nipples Bosses as per BS3799

| Alloy 20 bosses | Alloy 20 bosses Alloy 20 Carpenter Forged bosses Alloy 20 bosses Alloy UNS N08020 Forged bosses Carpenter 20Cb3 bosses ASTM B462 Alloy 20 Carpenter bosses |

| Alloy 20 Hex Nipples | Alloy 20 Hex Nipples Alloy 20 Carpenter Forged Hex Nipples Alloy 20 Hex Nipples Alloy UNS N08020 Forged Hex Nipples Carpenter 20Cb3 Hex Nipples ASTM B462 Alloy 20 Carpenter Hex Nipples |

| Alloy 20 Pipe Nipples | Alloy 20 Pipe Nipples Alloy 20 Carpenter Forged Pipe Nipples Alloy 20 Pipe Nipples Alloy UNS N08020 Forged Pipe Nipples Carpenter 20Cb3 Pipe Nipples ASTM B462 Alloy 20 Carpenter Pipe Nipples |

Description

Alloy 20 is an iron-base, austenitic alloy with excellent corrosion resistance to a number of different media and proves to be useful in a number of applications such as flue-gas desulfurization, chemical processing, food processing and storage as well as pharmaceutical applications to name a few. Application of the alloy could result in real cost savings when carefully compared to higher-cost alloys to determine if the necessary resistance is obtained in the chosen media. Applications are limited to a maximum temperature of 1000°F per ASME.

Resistance to Corrosion

Resistance to sulfuric acid is particularly exceptional but the alloy shows useful resistance in phosphoric acid, nitric acid as well as in chloride environments. Alloy 20 is an excellent option when chloride stress corrosion cracking is an issue and resists pitting and crevice corrosion.

Fabrication and Heat Treatment

Alloy 20 can be formed by either hot-working or cold-work using traditional methods. Hot forged material should be heated between 2100°F and 2250°F with careful temperature control insuring that the material not fall below 1800°F prior to forging. After hot working, anneal the material by heating to 1725°F and 1850°F for a minimum of 30 minutes per inch of thickness followed by water quench.

When stress relieving is desired, heat to a temperature below

1000°F followed by water quench after the desired time at

temperature

has been established. Annealing Alloy 20 should be between 1725°F

and 1850°F for 30 minutes at temperature per inch of thickness. A

lower hardness can be obtained by heating to 2100°F but his may

have a negative effect on the stabilization of the alloy.

Welding Alloy 20 is commonly performed via, TIG, MIG as well as submerged arc welding (SAW) using either the matching filler metal, ER320LR for TIG and MIG and E320LR for SAW. When welding to dissimilar alloys such as 316 or higher alloys such as C276 and Alloy 22, AWS ERNiCrMo-3 can be used for TIG and MIG while using ENiCrMo-3 for SAW.

Specifications

N08020, ASTM B473, ASME SB473, COLD DRAWN, HOT FINISHED, EN 10204-3.1, ASME SA 240, ASME SB 366, ASME SB 463, ASTM A 240, ASTM B 366, ASTM B 463,

Common Trade Names

INCOLOY® alloy 20, Carpenter® 20 alloy, 20CB-3®

INCOLOY® is a registered trademark of the Special Metals Corporation group of companies.

Carpenter® and 20CB-3® are registered trademarks of Carpenter.

Chemical Composition:

| Element | Nickel | Chromium | Molybdenum | Copper | Columbium + Tantalum | Carbon | Iron |

| Avg. Nominal % | 32.5 - 35.0 | 19.0 - 21.0 | 2.0 - 3.0 | 3.0 - 4.0 | 1.00 Max | 0.06 Max | Balance |

6. Corrosion resistant ASTM B462 Alloy 20 Carpenter 20Cb3 N08020 Hex Nipples Pipe Nipples Bosses as per BS3799 Test Certificates

We provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc

Material Testing:

We ensure that all our materials go through strict quality tests

before dispatching them to our clients.

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Chemical Analysis – Spectro Analysis

• Positive Material Identification – PMI Testing

• Flattening Test

• Micro and MacroTest

• Pitting Resistance Test

• Flaring Test

• Intergranular Corrosion (IGC) Test

Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of

boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce

or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204

3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record,

WPS/PQR

• Form A for the purposes of the Generalized System of Preferences

(GSP)

7. Corrosion resistant ASTM B462 Alloy 20 Carpenter 20Cb3 N08020 Hex Nipples Pipe Nipples Bosses as per BS3799 Packaging

We focus on every procedure to assure quality, the package we usually take is pack ASME B16.11 Forged Threaded ASTM B462 Alloy20 N08020 pipe nipples with environmental poly bags, and then in free fumigation wooden cases or wooden palte. Also can accept customized package such as OEM by negotiation. We offers just about everything to meet your Alloy20 Forged pipe nipples pack requirements. Lot of emphasis is placed on the packing and packaging. The Alloy20 swaged nipples are packed in wooden corrugated boxes foiled in plastic wraps and bubble wraps.

8. Corrosion resistant ASTM B462 Alloy 20 Carpenter 20Cb3 N08020 Hex Nipples Pipe Nipples Bosses as per BS3799 Quality Certificate: