Guangzhou Haoshun Mold Tech Co., Ltd. |

|

Cnc Machine Customized Small Nylon Gear Epicyclic Gear Plastic Parts For Machine

| Part Name | Cnc Machine Customized Small Nylon Gear Epicyclic Gear Plastic Parts For Machine |

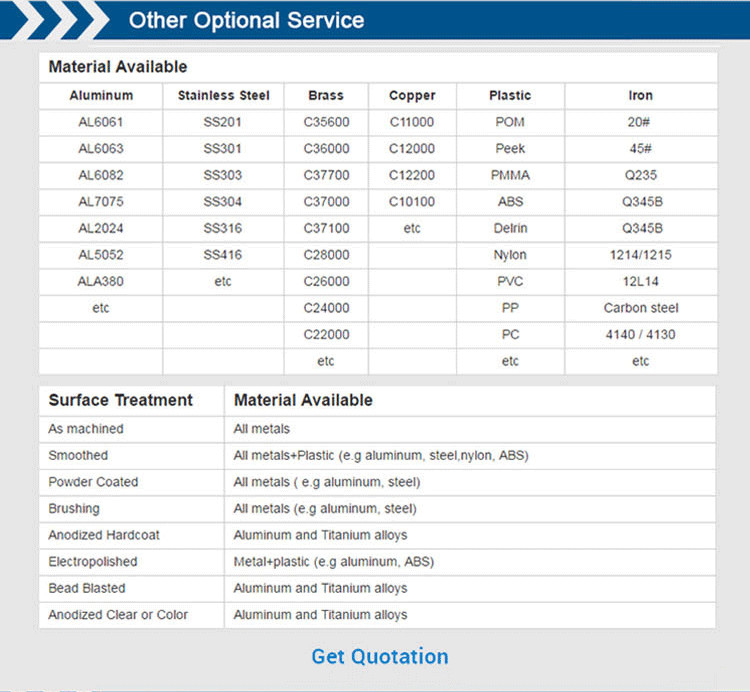

| Material | Aluminum ,Stainless steel ,Steel,Brass,Copper, Plastic |

| Surface Finishing | Anodizing, Plating, electroplating, Sandblasting, Painting, Powder Coating /Sandblast/ Electroplating/Colour Anodize |

| Main Product | Injection Mould/Tooling, Plastic molding parts, Structural foam molding parts, Gas- assisted molding parts, Prototype, Die casting, etc. |

| Usage | For Auto Parts, For Medical Parts, For Household Parts, etc |

| Machining Machines | Milling, Grinding, CNC, EDM, Wire Cutting, Carving, Lathes, Surface Finish, etc. |

| Quality System | ISO9001 |

About Us

HMT has with 15+ years experience in the 3D printing and CNC industry, our own factory, QC department, R & D and Sale department,and we can provide CNC Machining, 3D Printing Project One-Step Service.Also we can provide CNC Machining, 3D Printing,Professional OEM & High Precision Making For All Kind Of Products.We are a has Famous Brand CNC Machining, 3D Printing Supplier.

1) Material: Alloy 1050, 1060, 6061, 6063 etc.

2) Surface Treatment: Powder Coating /Silver Anodized & Black

Anodized /Electrophoresis /Mill Finish 5/Polish etc.

3)Coating Color: silver,white, black and so on.

4)Packing:Protective film, pearl cotton paper, hot shrink film

wrap, string, woden case,or according to customers' need.

| aterial | aluminum 6061,copper , steel , brass ,Various plastic,stainless steel , aluminum alloy : 6061,6082,6063,7075 ,5052 ...etc |

| Surface treatment service | 1.Bead Sandblasting 2.Anodizing 3. Powder coating 4. Painting 5. Alodine / passivation 6. zinc plating 7. silk printing 8. Laser etching 9. Polishing 10. Teflon finish 11.Chrome plating |

| CAPBILITIES | 1.CNC MILLING 2.CNC TURNING 3.MOLD MAKING 4.PLASTIC INJECTION 5.DIE CASTING 6.CARBON FIBER PARTS FORMING 7.STAMPING 8. 5 axis cnc machining |

| SAMPLE TIME | 1. 3-10 days for machining parts 2. 25- 35 Days for molding parts |

| Quality Control | We will provide test report and pics before shipping |

| Test equipment | Cmm testing, Quadratic element measure. |

FAQ

Q: Are you a factory or trading company?

A: Haoshun is an injection mold and prototype factory in Guangzhou

of China, welcome to visit us.

Q: How can I get the quotation?

A: We will submit the quotation in 24 hours if getting detailed

information during working days. In order to quote for you earlier,

please provide us the following information together with your

inquiry.

1) 3D STEP of Files and 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing,

labels,delivery,etc.

Q: What are the main oversea markets of Haoshun?

A: Currently HMT regular oversea customers are from the US, Canada,

the UK, Italy, Germany, France and India etc.

Q: What should we do if we receive defective products?

A: If receive defective product, please send us the photos, we will

feedback to our engineers and QC departments and solve the problems

ASAP.

Q: How to pack the moulds and products?

A:1).For moulds, we will be coated one-layer anti-rust oil first,and

then also will be covered thin films on the mould, finally pack

into fumigation wooden case.

2).And as to products, we will pack into standard export cartons or

as per customer’s request to pack.

WHY CHOOSE US?

1. One Stop Service

We can offer part design, model building, rapid prototype testing and injection molding mass production services.A range of surface finishing, post-processing and assembly are also workable. Can bring you a convenient and efficient experience.

2. Non Disclosure Agreement

We can sign NDA with you and keep secret to your idea and design.

3. Professional Engineering Team

We have a professional engineering team, half of whom have more than 15 years of experience in the mold industry, especially tooling, pleastic molding products, CNC machining and 3D printing.

4. Fast Delivery Time

We have advanced technology processing machines and time-mobilized

staffs, so can finish prototype project within 3-5 days, prototype

mold within 15 days, and 3-5 weeks to make mass production complex

mold.

5. Quality Control Expert

We have passed ISO9001 Quality Management System Certification,

having onsite materials, toolings and parts inspection before

production and delivery.

6. Experienced Business Development Team

We have 15 business development specialists with good English capabilities and communication skills to know your need timely.

Welcome to Get a Quote