Jiangsu Hanpu Mechanical Technology Co., Ltd |

|

Verified Suppliers

|

|

Tubular type exchanger forced circulation MVR evaporator equipment

MVR tubular falling film evaporator

Working principle and characteristics:

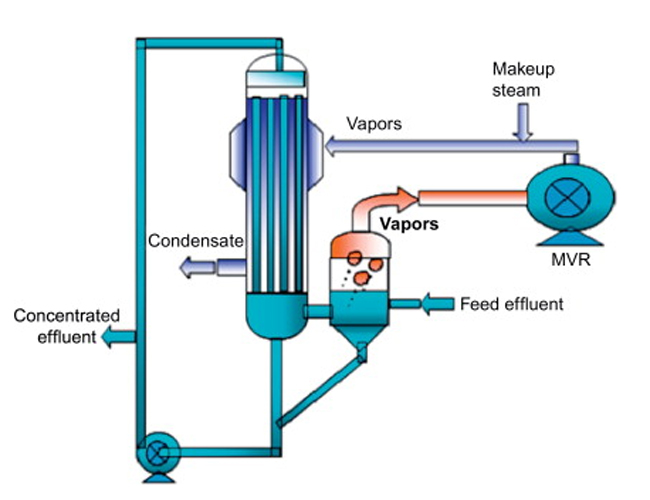

The material is added from the heat exchanger's upper tube box after it has been preheated by the preheater. Through the liquid distributor, the material is dispersed into each heat exchange tube, and a homogeneous liquid film is created along the inner wall of the heat exchange tube. During the process of flowing downward, the liquid film in the tube is heated by the heating steam on the shell side, boiling, and evaporating while flowing downward. The substance transforms into secondary steam and concentrated liquid at the heat exchange tube's bottom. The secondary steam enters the gas-liquid separator, and the concentrated liquid falls into the lower pipe box.

The characteristics of MVR falling film evaporator are as follows

1. The solution flows in a film shape in a one-way evaporator with high heat transfer coefficient;

2. It covers a small area;

3. For heat sensitive material, it can be made into one pass material, the material retention time is short, and it is not easy to cause material deterioration;

4. Low energy consumption;

5. Small liquid retention, easy to realize automatic cleaning.

MVR falling film evaporation system is suitable for the concentration of materials and pre concentration of salt crystallization. It is suitable for evaporating materials without particles, not easy to scale and with low viscosity, especially for heat sensitive materials.

Main features:

The MVR evaporator energy-saving technology is the most cutting-edge international evaporator technology, requiring only a small amount of live steam (during normal operation, almost no live steam is required), which significantly lowers business operating costs and lowers environmental pollution.

Due to adopt compressor supply heat source, there is little temperature difference which compared with traditional evaporator, and can achieve moderate evaporation,greatly improved product quality and reduce fouling.

No need condenser or only need small size condenser, the structure and process are quite simple, it can be full automatic operation, continuous running, safety and reliable.

This evaporator internal system equipped with CIP clean pipeline, which can achieve clean in place, easy to operate and without dead angle.

Liquid material can be evaporated under low temperature (50-100℃) in this evaporator, the liquid material is uniform and without running material, not easy coking, material heating denaturation is minimal.

Due to the utilization of 100% recycled secondary steam latent heat and total avoidance of live steam, the amount of steam used has been significantly decreased.Vacuum pumps can be used with heat-sensitive materials to achieve low temperature evaporation, with a minimum evaporation temperature of 50 °C. This can be done in close to absolute pressure under vacuum.

simple automation and process control—The falling film evaporator may be changed according to changing vacuum degrees, feeding capacities, concentrations, and temperatures due to the tiny amount of fluid retention, which is one of the fundamental requirements for steady product quality.The handling capability is up to 100T/h, and benefits include a small footprint, a compact design, steady operation, and more.

Mechanical Vapor Recompression MVR Evaporator consumption compared with traditional evaporation equipment calculated by evaporating 1T water

| Name | Steam | Electric Power | Total Cost (RMB) | ||

| Evaporation Capacity (kg/h) | Consumption (T) | Cost (RMB) | Consumption (kw) | Cost (RMB) | |

| Single Effect Evaporator | 1.1 | 220 | 3 | 2.1 | 222.1 |

| Double Effect Evaporator | 0.55 | 110 | 3 | 2.1 | 112.1 |

| Three Effect Evaporator | 0.4 | 88 | 3 | 2.1 | 90.1 |

| MVR Evaporator | 0.02 | 4.4 | 30 | 21 | 25.4 |

Working principle drawing

Product Details