Jiangsu Hanpu Mechanical Technology Co., Ltd |

|

Verified Suppliers

|

|

Removable Industrial Tvr Ball Type Vacuum Mvr Polluted Water Evaporator For Paper Making Salt Making

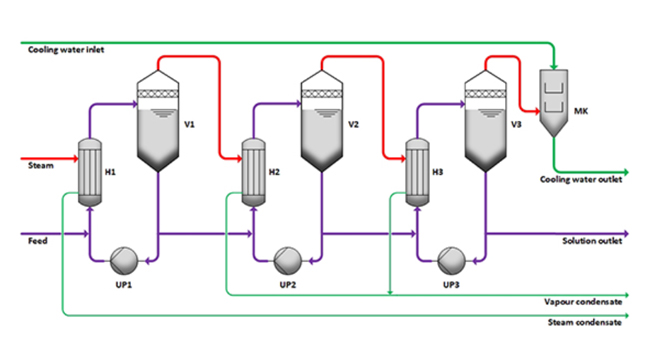

Process description – Example Parallel flow principle

The solution enters the evaporator circuit of the first stage. Here it mixes with the circulated solution and is heated in heater H with steam. In the evaporator V1, solvent (water) evaporates while cooling the solution to the boiling temperature.The first stage's evaporator circuit is where the solution is introduced. Here, it combines with the circulating solution and receives steam heating in heater H. In the evaporator V1, the water-based solvent evaporates as the solution is cooled to boiling point. The second stage, which is run at a lower temperature and lower pressure, receives the solution after that. The solution is evaporated in the second stage using the vapour produced in the first stage as a heating medium. Depending on the elevation of the solution's boiling point and the frame circumstances at the time, this procedure may be repeated numerous times.

Structure

Multiple-effect falling film evaporator consists of (first-effect, second-effect, third-effect)separators and evaporators and pre-heaters,condenser and vacuum pump, feeding pump,circulation pump, discharge pump, condensed water pump, pipeline and fittings, etc. It is equipped with vacuum gauge, thermometer,pressure gauge,and so on.

Characteristic

1. Evaporation rate: 500 kg per hour to 80 tons per hour

2. Stainless steel 304 or 316L as the material; 3. A fully closed

process with rapid evaporation at low temperatures;

4. Since seamless sanitary pipes have a mirror finish inside, it is

difficult to attach materials to them.

5. Low evaporation temperature: A portion of secondary steam can be

inhaled into a single-effect heater by a spray type hot pressure

pump. It is simple to clean. As a result, the heat would be fully

utilized, and the temperature for evaporation is low.

6. Large concentration ratio: adopt falling film evaporation, which

make the material liquid with larger viscosity be easy to flow and

evaporate, hard to scale, short concentration time.

7. This equipment can realize automatic production, intellectual

system management.

8. Can be designed into different technological process according

to the different characteristics of the materials and different

users' requirements.

Application

Multiple Effect Evaporators are widely used in the following areas as per the requirement.

Effluent Treatment: Industries like Chemical, Pharmaceutical, Textile, Dyeing, Breweries, Automobiles, Milk, Food industries etc, generates process effluents which are harmful to the environment. These effluents generally consist of water in huge amount and waste(contaminants). By evaporating the water from the effluent using MEE system results in the recycling of water.

Desalination: Reject of RO (Reverse Osmosis) have a huge amount of water. With MEE the water can be recycled.

Chemical Industry/ Pharma Industry: For the production of product the desired concentration is required or desired material need to be separated. Using MEE system desired concentration is achieved.

Milk Industry: Milk can be concentrated in the MEE system.

Sugar Industry: Sugar cane juice can be concentrated with MEE system.

Food industries: Tomato juice concentration, Sausages, Fruit juice concentration can be done in MEE system.

Advantages: Evaporation can be achieved with low consumption of heat source.

Typical three effect falling film evaporator specifications and technical parameters:

Parameter/ Specifications | HP-3.0 | HP-4.5 | HP-6.0 | HP-9.0 | HP-12.0 | HP-15 | HP-20 | HP-24 | HP-30 | HP-50 | |

Evaporation capacity(kg/hr) | 3000 | 4500 | 6000 | 9000 | 12000 | 15000 | 20000 | 24000 | 30000 | 50000 | |

Consumption of raw steam(kg/hr) | 900 | 1350 | 1800 | 2700 | 3600 | 4500 | 4500 | 7200 | 9000 | 15000 | |

Vacuum degree of each effect | First Effect | 0 | |||||||||

Second Effect | 448 | ||||||||||

| (mmHg) | Third Effect | 640 | |||||||||

Evaporation temperature of each effect | First Effect | 99 | |||||||||

Second Effect | 76 | ||||||||||

Third Effect | 53 | ||||||||||

Steam pressure for evaporation(MPa) | 0.6-1.0(Absolute pressure) | ||||||||||

| Solid content in feed(%) | 6-7(Corn pulp example) | ||||||||||

| Solid content outlet(%) | 42-48(Corn pulp example) | ||||||||||

Our Production Site