Chengdu Gute Machinery Works Co., Ltd. |

|

Verified Suppliers

|

|

Overview

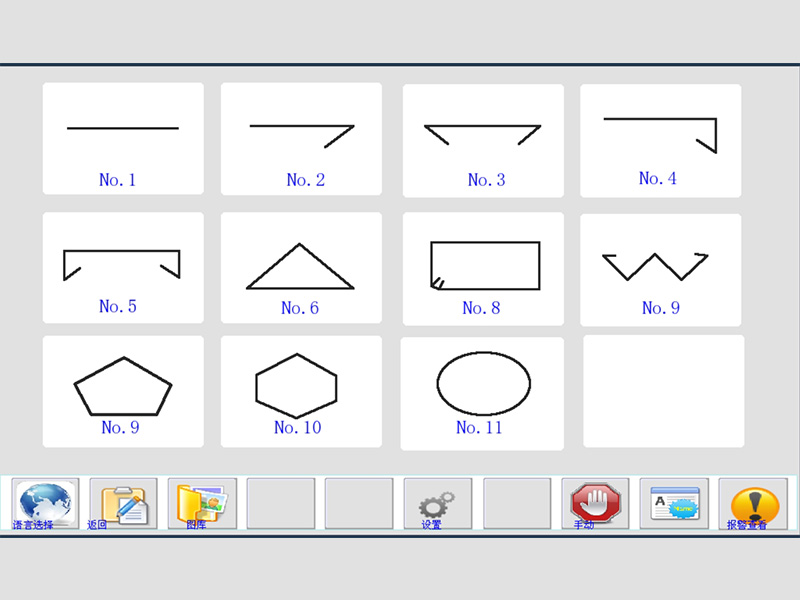

It can be bent in two directions and in two lines, and the processing capacity is very comprehensive. At the same time, the return mechanism and the material rack can be used to complete the production of hook ribs and plate ribs, realizing multiple uses in one machine. The equipment uses a numerical control system, and controls the servo system through a touch screen and PLC. The finished stirrup has high processing accuracy, stable and reliable quality, and has strong graphic storage capabilities. It is simple to operate and convenient to set up, which can save a lot of labor and waste. Improving processing efficiency is an indispensable part of modern construction buildings, and it is also an intelligent equipment that meets national standards.

Scope of application

Mainly used in the construction of housing construction, highways, roads and bridges, subways and other projects

Device parameters

| Single wire bending diameter | 5–13mm |

| Rebar double wire bending diameter | 5–10mm |

| Processing material | Steel Coil |

| Maximum towing speed | 100 m/min |

| Maximum bending speed | 1050°/sec |

| Rib straightness error | 0.02/1m |

| Total power | 48KW |

| Power consumption | 7KW/H |

| Stirrup length accuracy | ±1mm |

| Rib length accuracy | ±5mm |

| Angle accuracy | ±1° |

| Maximum bending angle | ±180° |

| Longest stirrup side | 1000mm |

| Shortest stirrup side | 90mm |

| The longest length of the rib | 7m |

| Working temperature | -5~40 ℃ |

| Traction control method | Servo |

| Bend control method | Servo |

| Loopback control method | Servo |

| Total Weight | 5.7T |

Equipment advantages

Our factory

Our service

Certification