Sunrise Foundry CO.,LTD |

|

Precision Investment Casting Carbon Steel Clamping Support Parts for Construction

Product Details

| Raw Material | Ductile iron, grey iron, carbon steel, alloy steel, stainless steel |

| Standard | ISO, EN, DIN, AISI, ASTM, JIS, GB |

| Casting Process | Green sand casting, resin sand casting, lost wax steel casting and silicon sol casting |

| Tolerance | ISO8062 CT5-CT9 |

| Roughness | Ra3.2-Ra12.5 |

| CNC Machines | 12 sets of MC and 20 sets of CNC lathes |

| Machining Tolerance | 0.01mm |

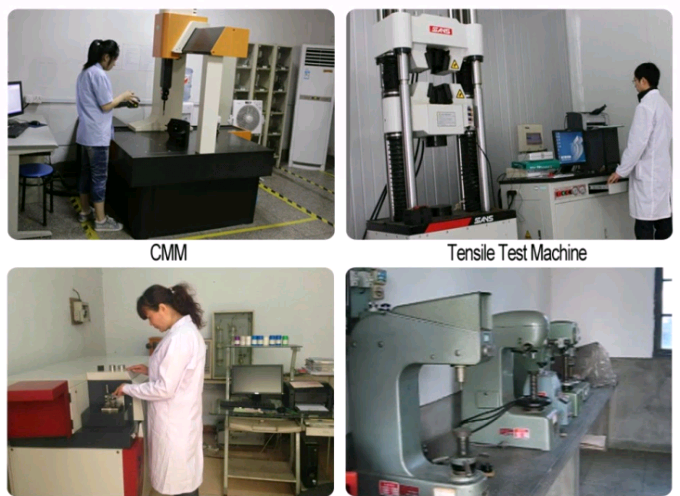

| Quality Control | The first sample checking, process monitoring and final quality checking |

| Finish | Phosphating, primer painting, anti-rust oil, powder coating, galvanized zinc coating, electro polishing and shot blasting |

| Certificate | ISO9001-2015, ISO14001-2015 |

| Service | OEM/ODM offered |

Product We Made

We divide our products into several categories. Gray Iron Casting, Ductile Iron Casting, Steel Casting, Stainless

Steel Casting for Scaffolding Accessories, Post Tension Anchorage, Automotive Part, Pump and Valve Body,

Pipe Fitting, Manhole Cover and Bollard, Ornamental Fence and Spear, Light Pole and Bench Casting, Railway Part.

Our Service

More than 20 years experience on manufacturing

Good Quality Material Used

Strictly Quality Control system

100% finished products are checked before shipment

Provide Technical servicesto clients in order to assist them with

their requirement

Experiencced Technical Team

Competitive price, Rapid Delivery, Excellent Services

Can ask for Technical Details of products

Quality Control

FAQ

Q: What is your lead time?

3-5 weeks for making new molds (OEM products);

2-6 weeks for mass production after order confirmation.

Q: Can we get samples?

A: Yes, we could offer the sample for free charge but do not pay

freight costs.

Q: Can you produce according to our own drawings?

A: Yes, OEM items are welcome.

If you have any question or any inquiry, please don't hesitate to

contact us.