Sunrise Foundry CO.,LTD |

|

Grey Iron Casting Rear Axle Housing Transmission for Tractor Part

Product Description

Rear axle housing transmission refers to a part of the vehicle's drivetrain that transfers power from the engine to the wheels. It is responsible for delivering torque to the rear wheels and plays an important role in the overall performance and handling of the vehicle.

The rear axle housing transmission consists of several key components, including the differential, axle shafts, and driveshaft. The differential is responsible for transferring power between the two rear wheels, while the axle shafts connect the differential to the wheels.

The driveshaft transfers power from the transmission to the rear axle housing. It is also responsible for keeping the wheels aligned and preventing vibrations or other drive-related issues.

Rear axle housing transmissions are essential to ensuring a smooth, safe, and efficient driving experience. They are commonly found on trucks, SUVs, and other large vehicles, and come in a variety of configurations to suit different driving needs.

Proper maintenance and repair of rear axle housing transmissions are critical to ensuring their longevity and continued performance. Regularly checking fluid levels, changing damaged or worn parts, and following manufacturer recommendations can prevent costly breakdowns and keep the vehicle running smoothly for years to come.

Product Details

Production Process

We have updated our production line. Our production process include Resin Sand Molding Line, Shell Molding Line,

Wet Green Sand Casting and Lost Wax Investment Casting Production Process.

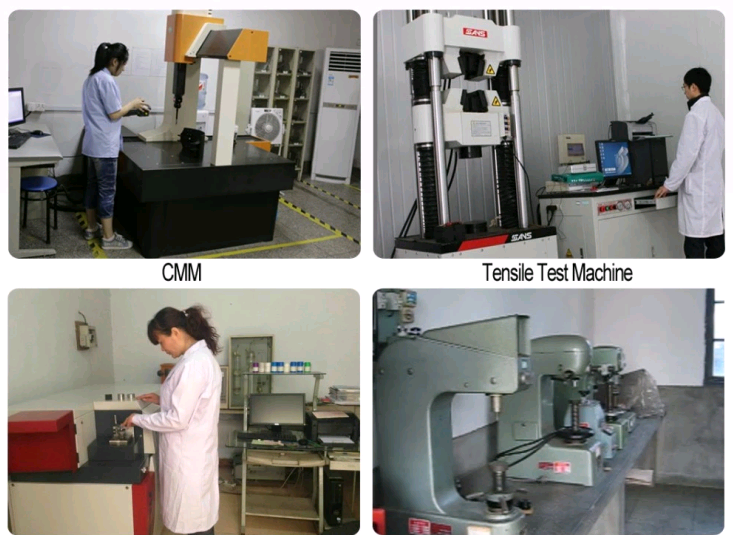

Quality Control

FAQ

A: We are manufacturer.

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.