Sunrise Foundry CO.,LTD |

|

Silica Sol Investment Casting Stainless Steel Casting

Product Details

| Process | Investment casting Shell mold casting Lost wax casting |

| Processing Ability | Surface finishment: Ra1.6-Ra3.2 |

| Size tolerance: VDG P690 D2 | |

| Maximum size: ≤1200mm×800mm×400mm | |

| Weight range: 0.1Kg-120Kg | |

| Material | stainless steel, carbon steel, alloy steel, heat-resistant steel, hardend steel,mild steel |

Brass CuZn38,H62 Aluminum bronze AB2,863 | |

| Cast aluminium alloy ZL101,ZL114A,A356 | |

| Application | Mechanical Components/parts Boat parts and Marine hardware Construction hardware Auto parts and accessories Medical Instrument parts pump & valve parts and accessories Impellers and propellers(propellors) Pipe Fittings or pipeline accessories Other industry metal casting parts |

| Design | Various type of 2D or 3D drawings are acceptable,such as JPG,PDF,DWG,DXF,IGS,STP,X_T,SLDPRT etc. |

| Standards | AISI,ATSM,UNI,BS,DIN,JIS,GB etc. |

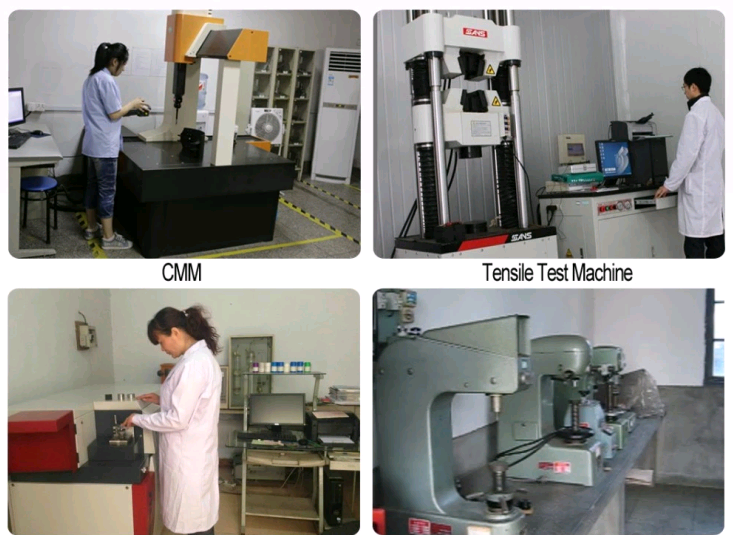

| Inspection | Dimension inspection Chemical composition analysis (Spectrum analysis) Mechanical property testing X-Ray inspection Dye penetrant inspection Magnetic powder inspection Metallographic inspections |

About Us

Sunrise Foundry is a professional Metal Foundry, located in Ningbo. We have been producing Gray Iron,

Ductile Iron Castings and and any other precision castings for more than 25 years.

We are dedicated to meet different requirements of various customers across the world, products are mainly

involved Agricultural and Construction Machinery, Hydraulic, Mining industry, Municipal Products, some steel

and stainless steel castings for Pumps and Valves, Pipe Fittings, etc.

Please feel free to contact us if you have any requests.

Production Process

Our factory supply OEM service(custom service) in precision investment casting,which are also called lost wax casting, We have been committed to this technique for over 25 years . Our specialized engineer can provide you the full-service of technology advice and products improving projection,and also reduce the cost of the parts.

Quality Control

Quality Control is one of the most important process in production. We insist that 100% inspection before

shipment and ensure parts without any flaws when sending out.

We have complete quality inspection facilities including mechanical testing, chemical analysis, tensile strength,

hardness, spectrometer, ultrasonic testing, etc.

FAQ

How could I get a sample?

Before we received the first order, please afford the sample cost and express fee. We will return the sample cost back to you within your first order.