Sunrise Foundry CO.,LTD |

|

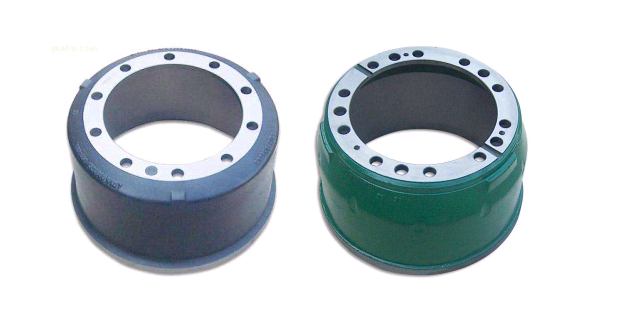

HT250 Grey Cast Iron / Resin Sand Casting Brake Drum for Heavy Duty

Truck Trailer

About Us

We specialize in production of Braking Hub(Brake Drum) for all

kinds of automobile & trailer& tractors. We have

completed production line and have advanced equipments for

Casting, Machining and quality testing.

Product Description

| Working life | Long life time, above 60000-80000kms |

| Application | Auto brake system |

| Material: | Gray iron HT250 |

| Weight | 20kgs-85kgs |

| Chemical composition | C:3.0-3.3% Si:1.6-1.9% Mn:0.7-0.9% P:<0.12% S<0.12% |

| Quality: | Meet or Exceed OE Manufacturer Specifications; |

| Certification | ISO/TS16949 |

| Package | 1.PP bag+individual box+outer carton+pallet; |

| 2.According to buyers' requirements. | |

| OEM/ODM | Both |

| Port | Ningbo |

| QC | 1. Sample check; |

| 2. Before production, mould and model check; | |

| 3. Technicians self check in production; | |

| 4. Engineer spot check; | |

| 5. Packing check; | |

| 6. Check before shipping. |

2. Machining: CNC machining center.

3. Inspection: Advance test equipment including CMM, tensile

strength testing machine, hardness tester, spectrometer, parallel

tester, etc.

4. Every detail contributes to our products of consistent quality

and excellent performance.

FAQ

Q: How about your packing?

A: One piece one plastic bag or according to the customers'

requirement.