Sunrise Foundry CO.,LTD |

|

Description

Factory Information

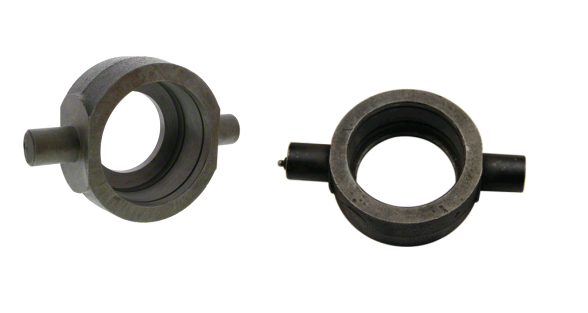

| 1. Product Name: | Trunnion Bearing Housing |

| 2. Place of origin: | Ningbo, China |

| 3.Lead time: | 25-30 days |

| 4.Payment term: | T/T, Sight L/C, etc |

| 5. Trade term: | FOB, CIF, etc |

| 6.Application fields: | Construction, Industry, Agricultural, etc |

| 7. Material range: | Alloy Steel, Carbon Steel, Stainless Steel, High Mn Steel, High Cr Iron, Ductile Iron, Gray Iron, Resistance Cast Iron |

| 8. Material Standard: | ASTM, AISI, ASME, SAE, NF EN, DIN, ISO, BS EN, SS, etc |

| 9. Process: | Investment casting, Precision casting, Lost wax casting, Silica Sol casting, Water glass casting, Foundry, steel foundry, Quartz sand casting, Furan resin sand casting, CNC Machining |

| 10. Software for specification drawings: | Pro-E, Solid work, PDF, JPG, Auto CAD |

| 11. Inspection equipment: | Spectrograph, Tensile Strength Test Machine, Impact Test Machine, Rockwell hardness Tester, hardness Tester, Magnetic Defect Detector, Ultrasonic Flaw Detector, X-Ray Test |

| 12. Machining Equipment: | CNC Machining Shop, Lathe, Milling Machine, Drilling Machine, Boring Machine, Grinding Machine, Heat treatment Furnaces |

| 13. Dimension Inspection: | Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge, three coordinates measuring instrument |

| 14. Surface treatment: | Cold/ Hot Zn Plating, Blackening treatment( Salt Spray Test 48-96hours), Ni Plating, Cr Plating, Spraying undercoat, Anti-rust Paint, Surface Paint, Plastic Paint, Coated Anti-Rust Water, Anti-Rust Oil, etc |

| 15. Surface Heat Treatment: | Medium Frequency Quenching, High Frequency Quenching and Carburizing and Quenching, Oil Quenching, Water Quenching, Normalizing, Temper, Annealing, etc |

| 16. Heat treatment Machine: | Mesh-belt Furnace, Carburizing Quench Furnace, Chamber Furnace, etc |

| 17. Packing: | Wood carton, Cardboard Carton, or according to customers' requirement |

| 18. Annual Output: | 8000-10000 Ton |

| 19. Certification System: | ISO 9001 Registered |

FAQ

Q: Do you test your products before shipping, what if there is any

quality problem?

A: We 100% test our products before shipping. If any quality

problem does happen, we will replace all the faulty ones at our

shipping cost, or refund to you.

Q: What about lead time?

A: For first order, usually lead time around 45-60 days. For repeat

order, usually around 30-45 days.

Q: Do you make custom parts?

A: Absolutely definitely YES! Outperforming the factory original is

what we do. We could make parts according to your sample or

drawing, and we could offer suggestions on how to design the

products to make it stronger!