WalthMac Measurement&Control Technology Co., Ltd. |

|

Verified Suppliers

|

|

Optical Cable Sheath Material Saving Gravimetric Feeder Stabilize Production Lines

1. Products Introduction

The cable sheath Gravimetric Feeder delivers accurate

weight measurement, improving quality, efficiency, affordability,

and energy conservation. It stabilizes production and conserves raw

materials effectively.

2.Main Structure

| Controller | Tractor controls speed, extruder controls diameter, and synchronous speed control uses statistical data in production. |

| Display Unit | Real-time data reflection in production: output, meter weight, extruder speed, and haul-off speed |

| Laser Micrometer | Real time measurement of outer diameter value combined with the statistical algorithm of the Gravimetric Doservto calculate the meter weight value corresponding to the set outer diameter value, forming a closed-loop control |

| Detection Device | Dose raw materials and equip the Controller within the extruder. |

3.Features

4.Benefits

5.Applications

Perfect for the cable and optical fiber industries, the Gravimetric

Feeder effectively stabilizes sheath extrusion, resulting in

significant reduction in raw material consumption.

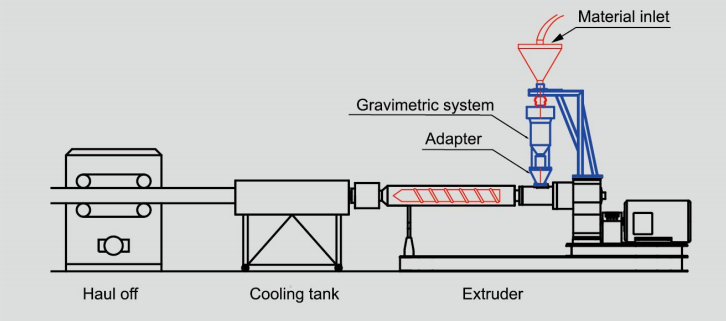

6.Way of installation

Customers are responsible for supplying the necessary bracket and

adapter for the installation of the Gravimetric Feeder on the

extruder, as the supplier may not be familiar with the production

environment.

7.On-sight Application

Our products have been widely adopted by companies globally,

receiving positive feedback from manufacturers.

8.Profile of WalthMac

Mianyang WalthMac Technology Co., Ltd. is a national high-tech

enterprise dedicated to achieving excellence in artistic product

manufacturing. We uphold rigorous standards in design, management,

and quality control, utilizing internationally certified machinery.

WalthMac is dedicated to embracing the future trend of smart

factories. Our products prioritize automation, enhancing quality,

optimizing material efficiency, and reducing reliance on manual

labor throughout the production process.

Since 2009, with a 14-year history, we have actively

engaged in global plastic and rubber exhibitions in countries such

as China, Vietnam, Thailand, USA, UK, and more. Through these

exhibitions, we have established long-lasting partnerships with

over 800 companies, including DEMUKA and GSM.

9.FAQ

Q1. What is your terms of packing?

A: Typically, our systems are packaged in wooden cases.

Q2.What is your items of payment?

A:We accept T/T or other payment methods. We will provide product and package photos for your review before final payment.

Q3.What is your terms of delivery?

A:EXW,FOB,CFR,CIF

Q4.Will you test the machine before exporting?

A:Yes,of course