WalthMac Measurement&Control Technology Co., Ltd. |

|

Verified Suppliers

|

|

Small Amount Of Raw Material Side Feeder Color Masterbactch Lose-In-Weight

1. Product Profile

Side Feeder is widely used in industries which need to feed small even micro amount of raw materials.Such as color masterbatch ,addivitives and other small density of granules.Here has a requirement of material shape,it must in granular.

2. Main Components

3. Parameter

| The application for material | Masterbatch,additives in granular |

| Model | GD-D-45 |

| Output | 1-25 kg/hr |

| Display unit | 7''/10'' inch touch screen |

4. Features

5.Applications

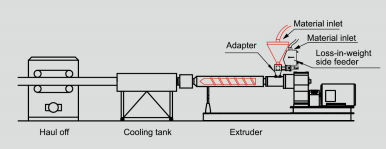

Below application is used on the extruders with our Gravimetric Control System,which are used for producing plastic pipes.

6.Installation

Installing an adapter on the extuder firstly,then set the Side Feeder on the adapter,there will have two hoppers to send materials into machine like picture show.

7.Profile of WalthMac

Mianyang WalthMac Technology Co., Ltd. is a national high-tech enterprise pursuing "product is art". We have set high standards for product design, internal management, and quality control.

Achieving a highly intelligent workshop in the future is the trend of factories in the future, and it is also the parent goal for Worth to strive for. Worth products focus on helping users achieve automation throughout the production process, from improving product quality and saving raw materials to reducing the dependence on labor throughout the process.

Since extablished in 2009,in these 14 years, we have participated in plastic and rubber exhibitions in China and other countries such as Vietnam,Thailand,America,England etc. We are cooperating with over 800 companies like DEMUKA,GSM etc, and establishing long-term cooperative relationships with them.