WalthMac Measurement&Control Technology Co., Ltd. |

|

Verified Suppliers

|

|

Feeding Color Masterbatch By Screw Side Feeder In High Precision

1.Product Description

Screw Side Feeder under WalthMac use the principle of

weight loss, high-precision weighing sensors are used to control

small or micro amounts of color master batches.Applicable

industries include plastic film, cable, pipe, raw material

production, etc

2.Main components

3.Parameter

Mechanism material | Stainless steel,aluminum alloy |

| Feeding error | <0.3-0.5% |

| Weighing resolution | 1/4000000 |

| Power | 50-200w |

4.Benefits

5.Scope of use

For the feeding of trace raw materials such as color masterbatches and additives in the fields of plastic film, cable, pipe, raw material production, plastic modification, and chemical industry.

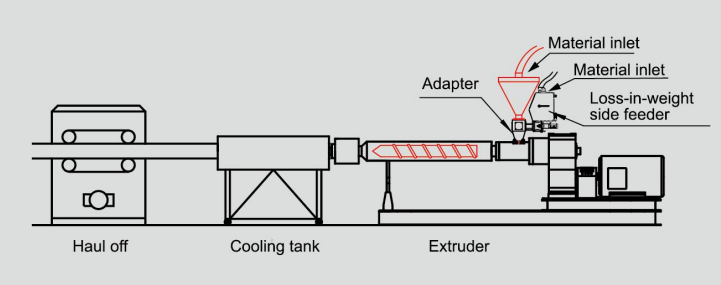

6.How to install system

Install an adapter under the system onto the extruder, and then install the system directly onto the adapter.

7.On-sight Application

8.About WALTHMAC

Mianyang WalthMac Technology Co., Ltd. is a national high-tech enterprise pursuing "product is art". We have set high standards for product design, internal management, and quality control.

Achieving a highly intelligent workshop in the future is the trend of factories in the future, and it is also the parent goal for Worth to strive for. Worth products focus on helping users achieve automation throughout the production process, from improving product quality and saving raw materials to reducing the dependence on labor throughout the process.

Since its establishment for 14 years, we have participated in rubber and plastic exhibitions in domestic and abroad every year, cooperating with over 800 companies like DEMUKA,GSM etc, and establishing long-term cooperative relationships with them.