WalthMac Measurement&Control Technology Co., Ltd. |

|

Verified Suppliers

|

|

Plastic Raw Material Mixing Machine Gravimetric Dosing Mixing System Made By Stainless Steel

1.Products Introduction

Gravimetric Dosing Mixing System under WalthMac mainly used for mixing raw materials of 2/4/6/8 components to obtain the precise ratio of raw materials required by the manufacturer. By precisely controlling the proportion of multi-component raw materials, in addition to obtaining the required mixture, it can also save on the use of raw materials.

2.Main Structure

3.Parameter

| HMI | 7'' Inch touch screen |

| Components | 4 components |

| Capacity | 1000kg/h |

| Feeding/dosing error | 0.1-0.3% |

| Language | Multiple Language Option |

4.Features

5.Benefits

6.Applications Scope

Gravimetric Dosing Mixing System has a wide range of application space, as long as it involves the proportion of plastic raw materials and mixing occasions, can use this product, such as plastic films/ cables/ pipes/ production of raw materials/ plastics modification and other industries such as Chemicals.

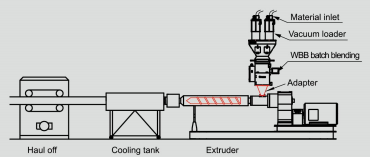

7.Way of installation

Installing Gravimetric Dosing Mixing System with an adapter on the extruder ,this method needs to convey raw materials once from storage to system by vacuum loader.

Installing the Gravimetric Dosing Mixing System on the floor with a platform,there will convey raw materials twice ,first step is from storage to system by vacuum loaders,second step is from the bottom hopper of Gravimetric Dosing Mixing System to vacuum loader upon the material hopper which set on the extruder.

8.On-sight Application

Most customers will send us the applications in their factories to give us a feedback.Over 60% proportion of domestic market was belonging to our machines.

9.Profile of WalthMac

Mianyang WalthMac Technology Co., Ltd. is a national high-tech enterprise pursuing "product is art". We have set high standards for product design, internal management, and quality control.During 14 years,we are cooperating with over 800 companies in the world and passed CE,ISO etc certifications.

Achieving a highly intelligent workshop in the future is the trend of factories in the future, and it is also the parent goal for Worth to strive for. Worth products focus on helping users achieve automation throughout the production process, from improving product quality and saving raw materials to reducing the dependence on labor throughout the process.

Since extablished in 2009,in these 14 years, we have participated in plastic and rubber exhibitions in China and other countries such as Vietnam,Thailand,America,England etc. We are cooperating with over 800 companies like DEMUKA,GSM etc, and establishing long-term cooperative relationships with them.

10.FAQ

Q1:Are you a trade company or manufacturer?

A:We are Manufacturer who design and sell machines.

Q2:What's the terms of payment?

A:Usually via T/T before exporting.

Q3:What's the deliver term?

A:For EXW,FOB,CIF,CFR can be accepted.