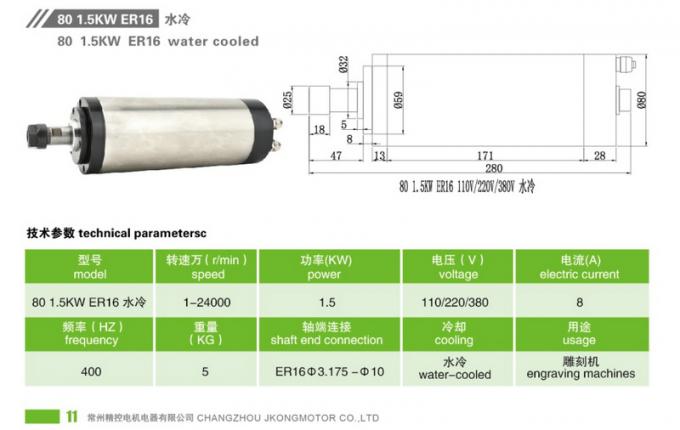

ER16 Water Cooled Spindle CNC Motor , 110V / 220V Inverter Kit Φ80

1.5KW

Spindle motors are powered by a Vector drive.

Some smaller machines use a power supply and servo amplifier to

power the spindle motor. On machines built before January 1997

spindle motors were powered by a Spindle Drive. Spindle motors are

used to drive various spindle configurations, which include

gearbox, direct belt drive, and inline spindle assemblies.

Electrical Specification:

Matching inverter: 1.5kw inverter

Spindle motor features:

1) Imported bearings with good quality, long working life.

2) Application: Milling,Engraving,Drilling in all kinds of CNC

Router machine.

3) There are water cooling spindle , air cooling spindle and self

cooling spindle for your choose.

4) Every spindle motor must be passed polishing process, Improve

spindle concentricity to increase motor working life.

Provide:

1. water cooling:800w,1.5kw,2.2kw,3kw,4kw,3.2kw,4.5kw,5.5kw

2. air cooling: 800w,1.5kw,2.2kw.3.5kw,4.5kw,6kw,7.5kw

| Model | Speep (RPM) | Power (KW) | Voltate (V) | current (A) | frequency

(HZ) | weight (KG) | cool | Phase |

| HJ2 Φ65 *208 | 1-2.4 | 1.5 | 220 | 8 | 400 | 3.2 | air | 3 |

| HJ3 Φ80*200 | 1-2.4 | 1.5 | 220 | 8 | 400 | 3.7 | air | 3 |

| HJ6 Φ80*160 | 1-2.4 | 1.5 | 220 | 7 | 400 | 4 | water | 3 |

| HJ7Φ80*170 | 1-2.4 | 1.5 | 220 | 8 | 400 | 4.5 | water | 3 |

Accessories:

We also have spindle motor matching inverter(VFD), collet , gripper

etc.

If you need other kinds of parts, please don't hesitate to contact

us.

TIPS:

The spindle motor of woodworking engraving machine is an important

component of woodworking engraving machine. The advantages and

disadvantages of the spindle motor directly affect the processing

speed and accuracy of the engraving machine. How to select

high-quality spindle motor is very important. ATO summarizes the

main points of woodworking engraving machine spindle selection for

the reference of users:

If we pursue the efficiency of woodworking engraving machine, we

should not only have a high speed, but also a large amount of

knives. For example, when processing solid wood, we need a spindle

motor with a power of more than 3KW.

Whether the spindle motor of woodworking engraving machine adopts

high-precision bearings or not, if it does not use high-precision

bearings, the performance is that the spindle motor overheated

after long-term high-speed rotation, which affects the service life

of the spindle motor.

Whether the spindle of woodworking engraving machine rotates at

different speeds, especially at high speeds, the sound is uniform

and harmonious.

Whether the radial force of the principal axis of woodworking

engraving machine is applied. The main reference is whether the

material with hard texture can be cut at high speed. Some spindle

motors can only cut hard materials at very low speed, otherwise the

performance of the motor will be seriously lost, which will affect

the accuracy of the spindle after a period of time, or even cause

faults.