HENAN TAIGUO BOILER PRODUCTS CO.,LTD. |

|

Verified Suppliers

|

|

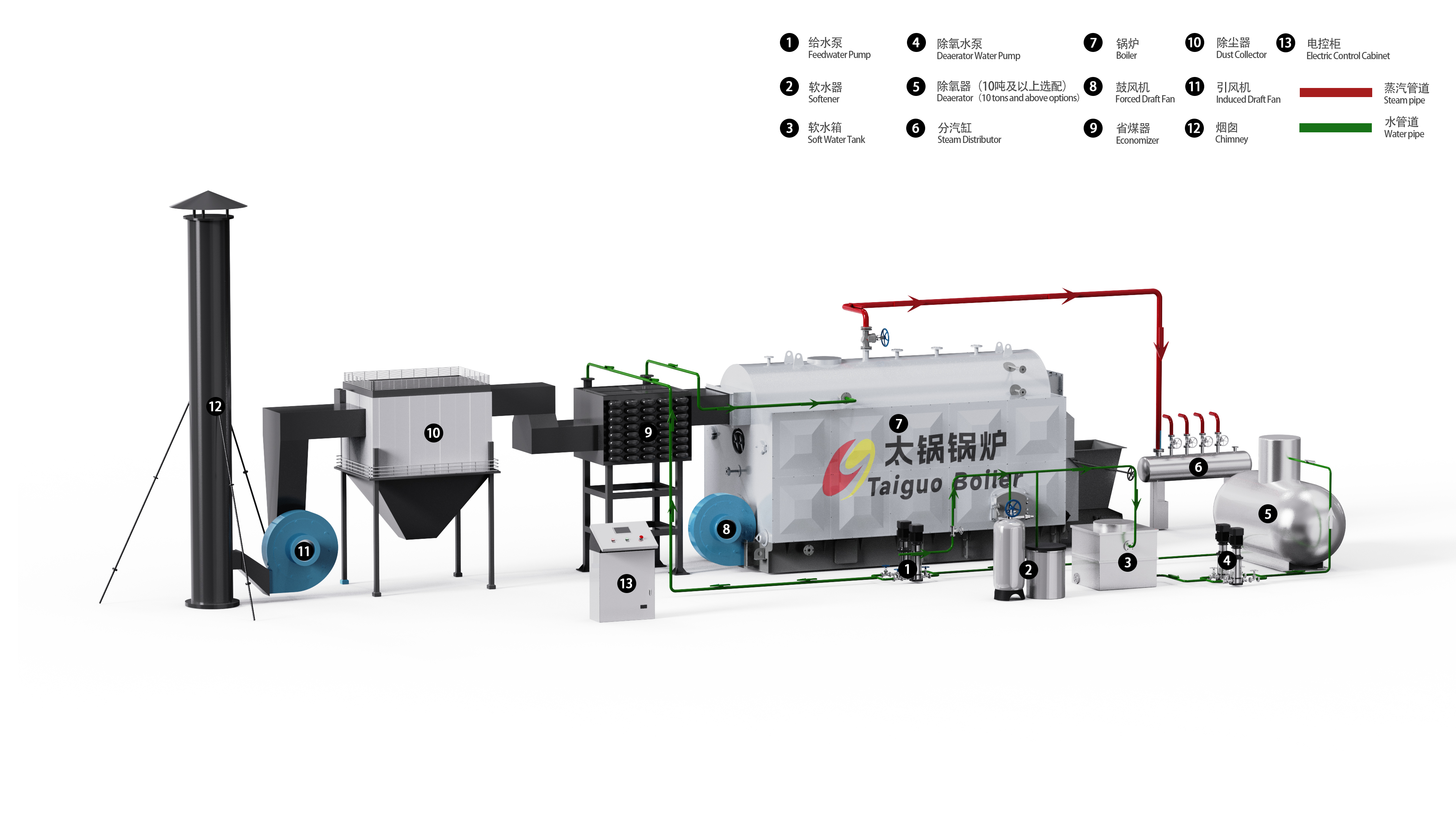

The new DZL series steam boiler is a single cylinder-type longitudinal water-fire tube shell boiler, and the combustion equipment is a chain grate. The water cooling wall on the left and right sides of the furnace is a radiant heating surface, the convection heating surface in the upper two wings of the furnace is a convection heating surface, and the threaded smoke pipe (with a diameter of 57×3) is arranged in the boiler drum. The furnace wall adopts a new process of heat-resistant concrete cast and rammed as a whole, and the outer side of the boiler main engine is a three-dimensional protective plate shell. This series of boilers use the latest scientific research results, such as: arch tube plate, threaded smoke pipe, secondary air and other new technologies, better solve the shell boiler tube plate cracks, low thermal efficiency, insufficient output, poor fuel adaptability and other problems.

(1) The cylinder is composed of arch tube plate and threaded smoke

pipe, so that the cylinder is changed from a quasi-steel body to a

quasi-elastic structure, and the pulling member in the tube plate

area is cancelled and the stress is reduced. The smoke pipe in the

tube plate is changed from two return trips to one return trips,

which solves the problem of tube plate cracks.

(2) Due to the arrangement of the rising pipe row in the lower part

of the drum, the dead water area at the bottom of the drum is

eliminated, so that the mud is not easy to deposit, and the lower

part of the drum has a refractory layer, so that the high

temperature area of the drum is not directly affected by the flame

radiation heat, and the lower part of the boiler shell is prevented

from bulging.

item |

DZL1 |

DZL2 |

DZL3 |

DZL4 |

DZL6 |

DZL8 |

DZL10 |

DZL12 |

DZL15 | ||

Rated evaporation capacity(t/h) | 1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 15 | ||

| Rated pressure(Mpa ) | 0 .7/ 1 .0/ 1 .25 | 0 .7/ 1 .0/ 1 .25 | 0 .7/ 1 .0/ 1 .25 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | ||

| Rated steam temperat ure( ℃ ) | 170/ 184/ 194 | 170/ 184/ 194 | 170/ 184 / 194 | 194/204 | 194/204 | 194/204 | 190/204 | 194/204 | 194/204 | ||

| Feed water temperat ure( ℃ ) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| Heating Area( m) | Body | ~33 | ~50 | ~75 | ~100 | ~170 | ~200 | ~250 | ~340 | ~415 | |

| Economizer | 20 .7 | 25 .3 | 28 .6 | 33 . 12 | 87 .2 | 98 | 145 | 168 | 189 | ||

| Effective area of garte ( m) | 2 .22 | 4 . 1 | 5 .85 | 6.2 | 7 .95 | 9 .75 | 10 .77 | 13 .4 | 16 .6 | ||

| Fuel type | Biomass pellet,wood sawdust,bamboo chip,wood block,straw ,Jute, palm shell | ||||||||||

Fuel Consumption (kg/h) | ~200 | ~400 | ~600 | ~800 | ~1000 | ~1200 | ~1400 | ~1600 | ~1800 | ||

| Flue gas temperat ure( ℃ ) | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ||

| T hemal efficiency(%) | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ||

Weight of biggest part for t ransportation(t) | 17 | 18 .5 | 20 | 25 | 35 | 45 | 58 | 64 | 77 | ||

| Overall dimension of biggest part for t ransportation( m) | 5 . 1*2 .2 *3 | 5 .5*2 .3 *3 .3 | 6 .4*2 . 4*3 .5 | 6 .6*2 .6 *3 .6 | 8 . 1*2 .9 *3 .8 | 8 .3*3 . 1 *4 .0 | 8 .6*3 .2 *4 .2 | 9 .8*4 .2 *4 .5 | 12 .9*4 *7 .5 | ||